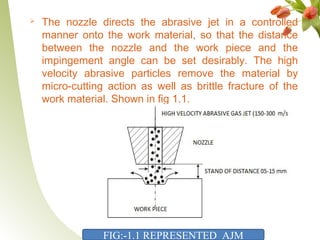

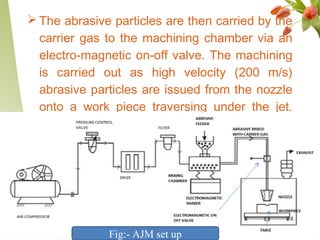

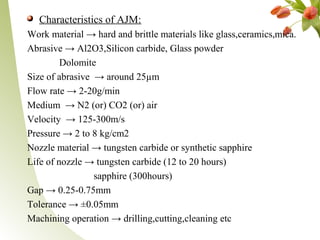

In abrasive jet machining (AJM), compressed air carries abrasive particles like aluminum oxide or silicon carbide through a nozzle to machine hard, brittle materials. The high-velocity abrasive particles remove material by micro-cutting and brittle fracture. AJM can drill intricate shapes, machine fragile materials, and is used for drilling, cutting, deburring, cleaning, and etching. Material removal rate is low, abrasives may embed, and environmental impact is high. AJM is suitable for hard, brittle materials like glass, ceramics, and mica.