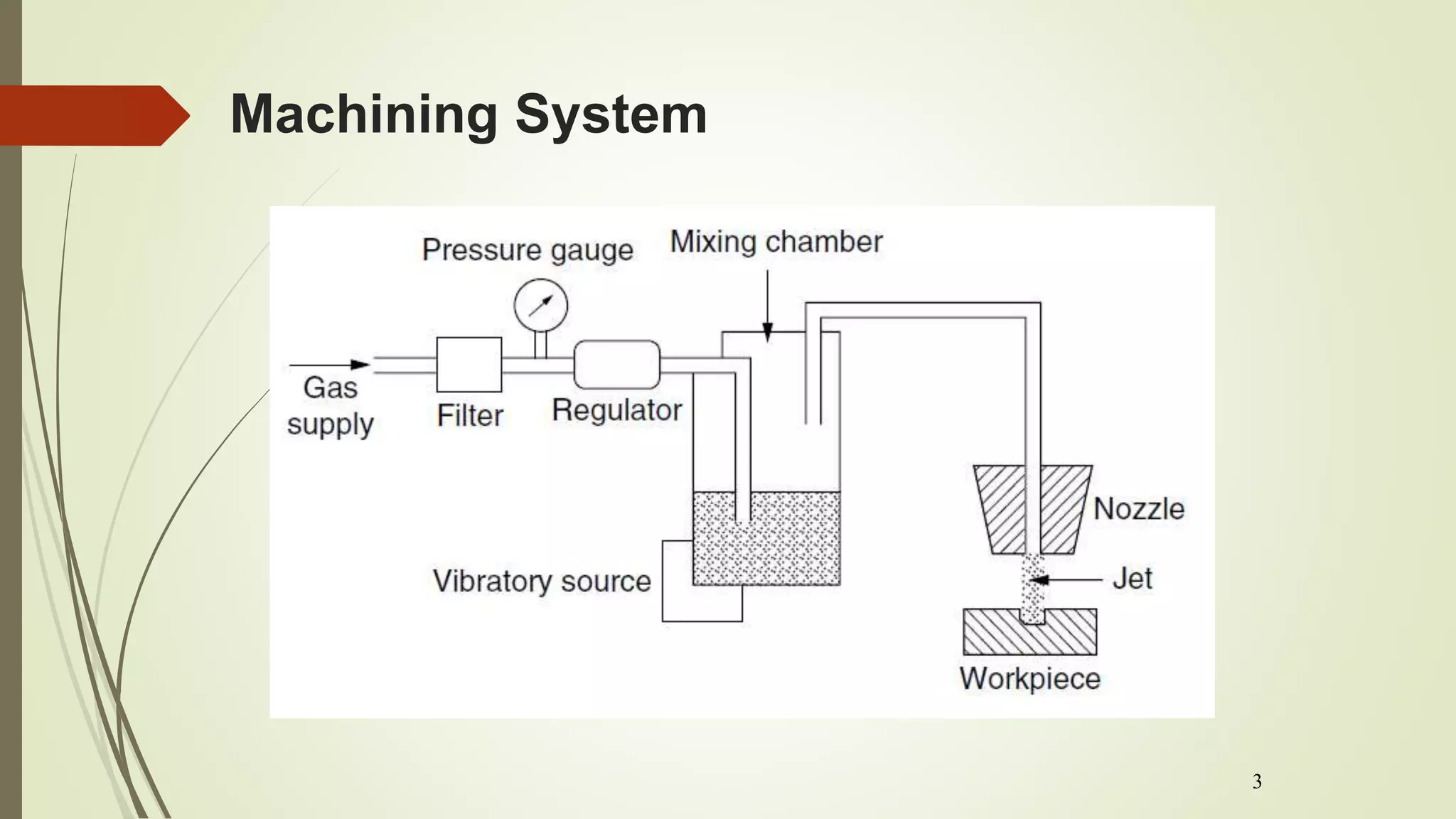

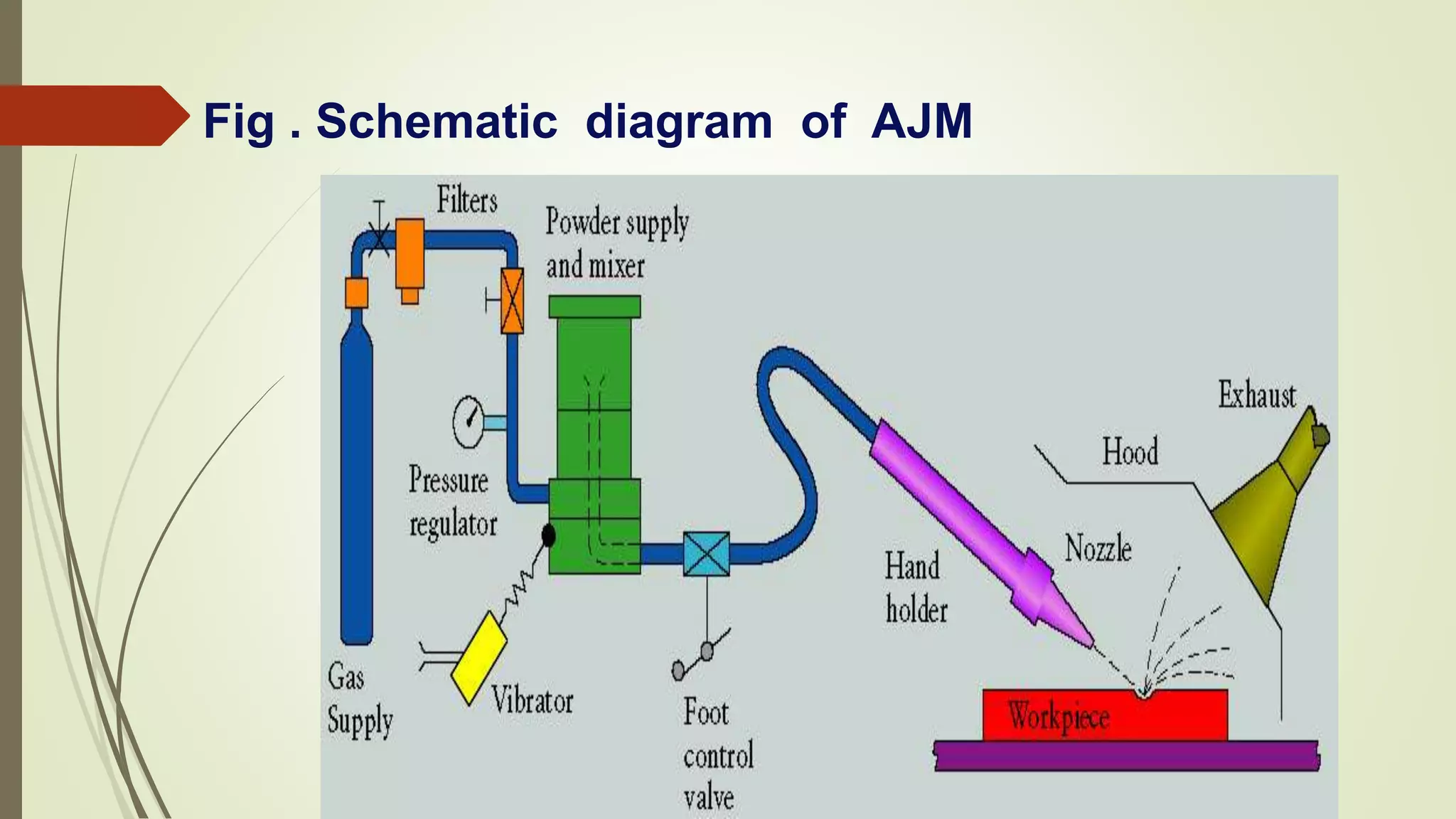

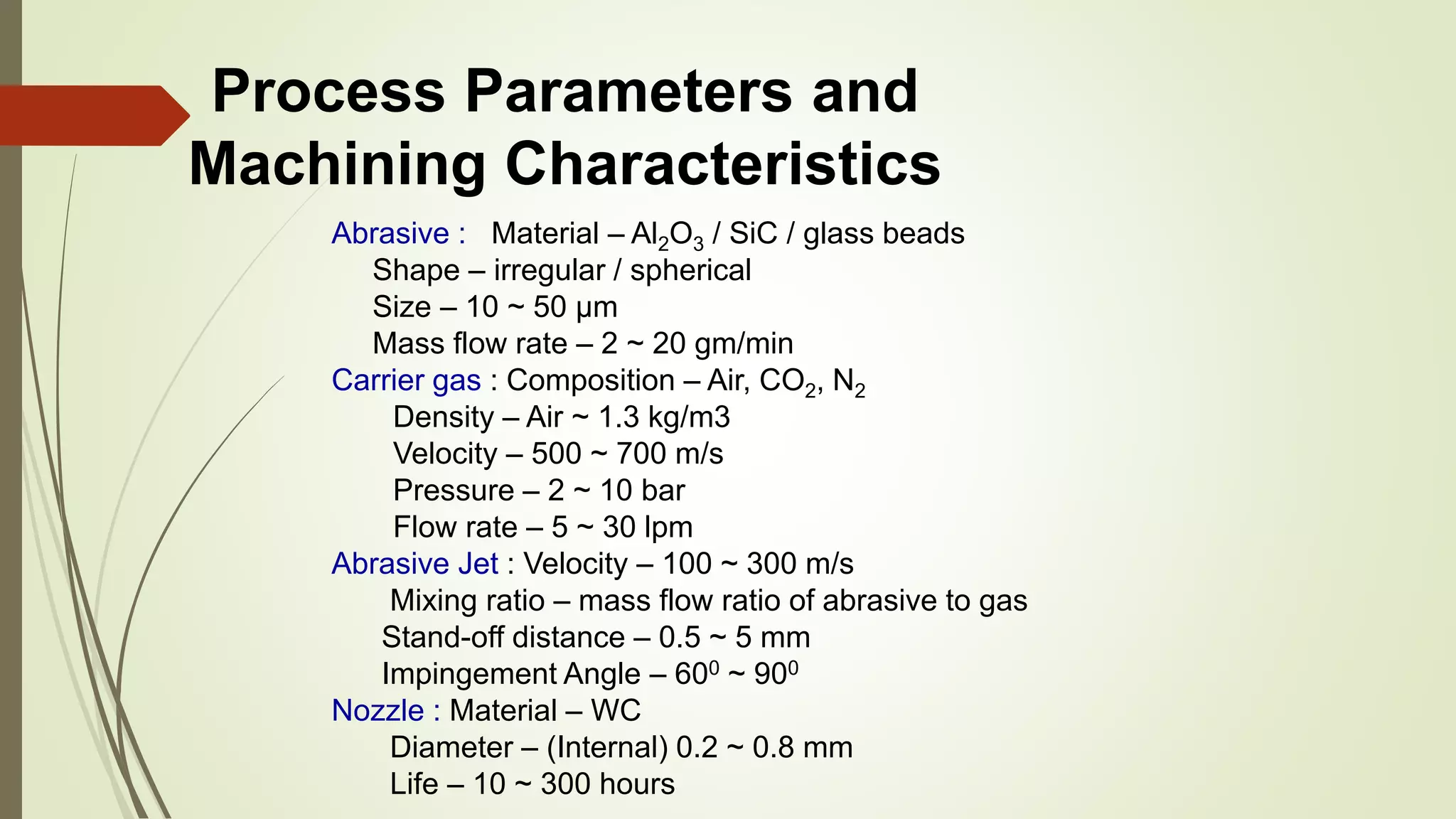

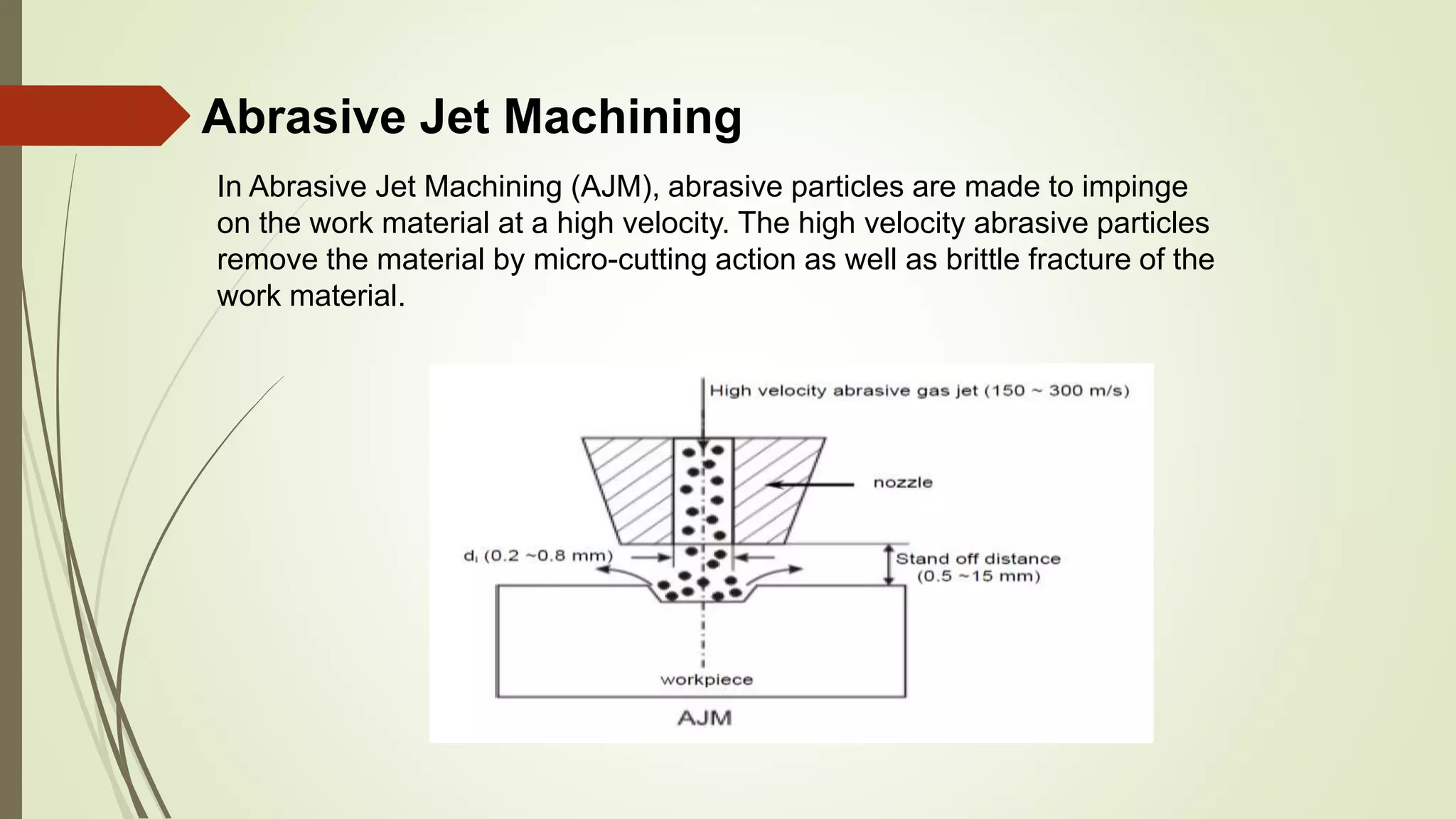

Abrasive jet machining involves a high velocity stream of gas or water mixed with abrasive particles being directed at a material to remove it. The process uses a mixing chamber to combine the abrasive particles like aluminum oxide or silicon carbide that are 10-50 micrometers in size with a gas like nitrogen or air. This mixture is then passed through a small tungsten carbide nozzle at speeds of 150-300 meters per second to machine the material.