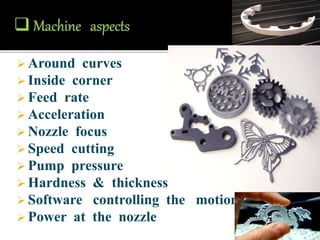

Abrasive jet machining (AJM) is a precision cutting process that utilizes a high-velocity stream of water or gas mixed with abrasives to remove material. Key components of AJM systems include pumps, nozzles, mixing tubes, and motion control systems, which together allow for precise, controlled cutting of a wide range of materials. The technique is effective for achieving high tolerances and features such as quick setup, low capital costs, and environmentally friendly operation, although challenges like abrasives not being reusable and tapering can arise.