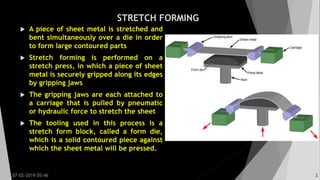

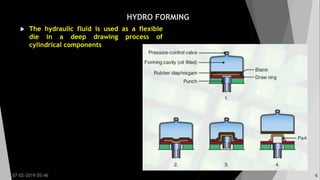

Stretch forming is a manufacturing process where sheet metal is stretched and bent simultaneously over a die to form large contoured parts. It is performed on a stretch press, where the sheet metal is gripped along the edges by jaws attached to carriages that stretch the sheet against a contoured form die. Special forming processes include hydro forming, where hydraulic fluid acts as a flexible die; rubber pad forming, where sheet metal is pressed between a die and rubber block; and metal spinning, where force is applied to sheet metal wrapped over a rotating mandrel to take its shape.