The document, authored by Endika Gandarias, explores comprehensive aspects of cutting tools and parameters essential for manufacturing technologies. It covers the selection of cutting conditions, tool geometries, and the effects of various cutting parameters on machining processes, emphasizing the importance of factors like cutting speed, feed rates, and machining time. Additionally, it discusses high-speed machining techniques and considerations in tool insert fabrication and performance.

![9

CUTTING TOOLS

by Endika Gandarias

Temperature [ºC]

Hardness[HRC]

1550

1400

1300

900

800

Ceramic

CBN

Carbide

(Hard metal)

Diamond

HSS

ºC](https://image.slidesharecdn.com/5cuttingconditions-170204214000/75/Cutting-conditions-9-2048.jpg)

![10

Feed [mm/rev]

Cuttingspeed[m/min]

50

CUTTING TOOLS

by Endika Gandarias](https://image.slidesharecdn.com/5cuttingconditions-170204214000/75/Cutting-conditions-10-2048.jpg)

![33

F [mm/min]

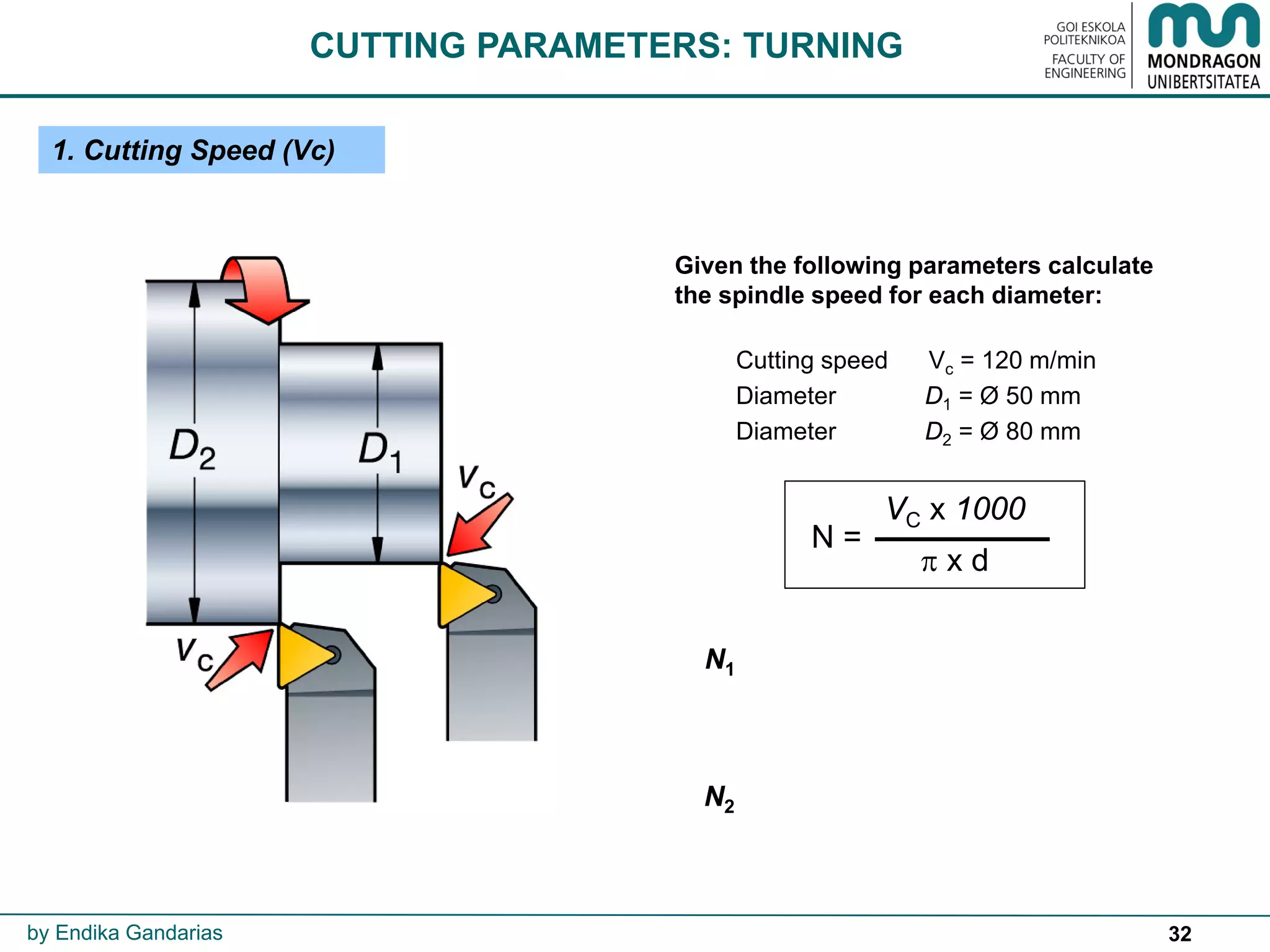

DEFINITION: Relative movement between the workpiece and the tool.

fn [mm/rev]

IN

TURNING

FEED PER

REVOLUTION

(fn)

→

2. Feed

3. Cutting depth (ap)

FEED PER REVOLUTION

F = fn·N

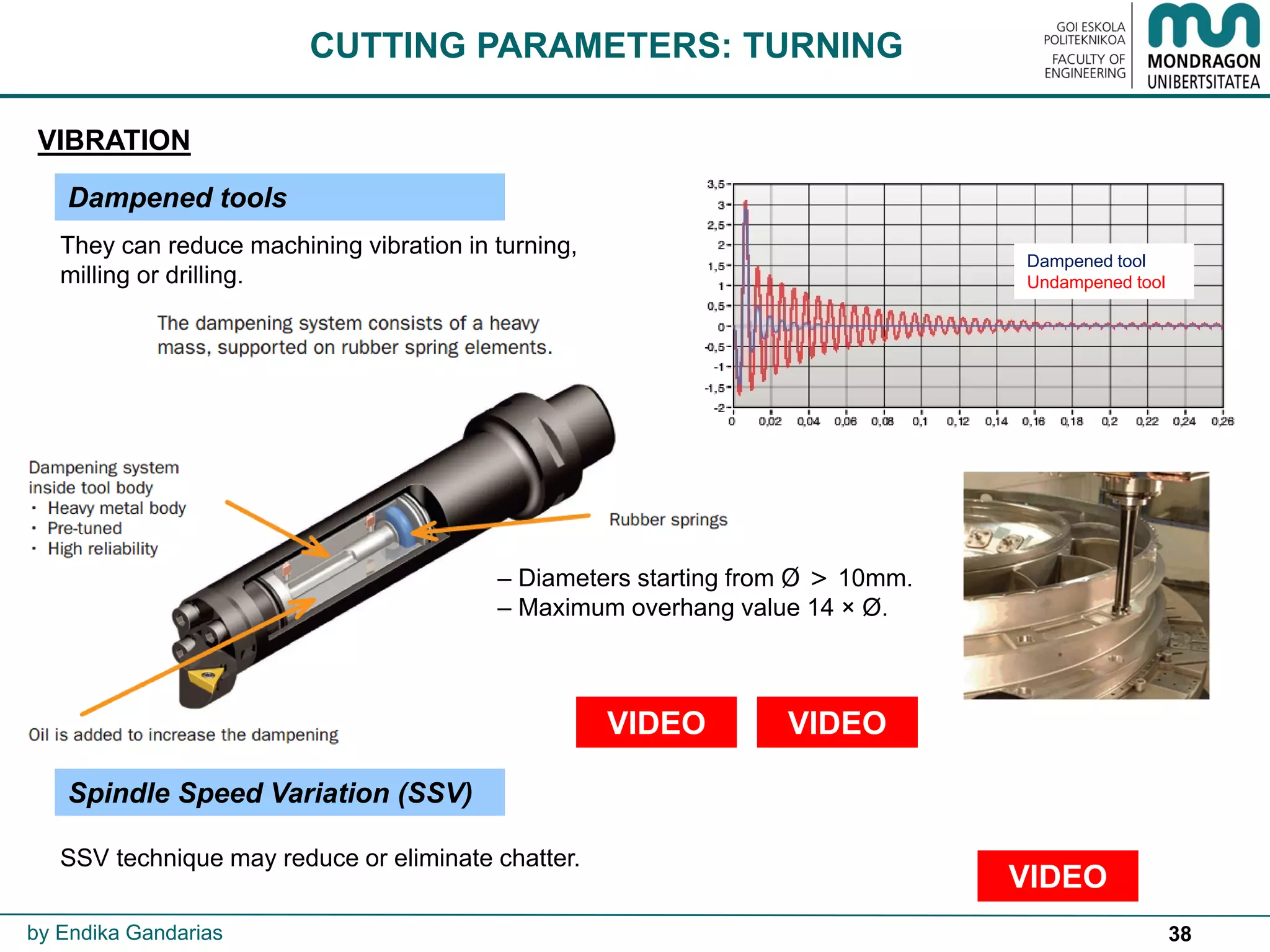

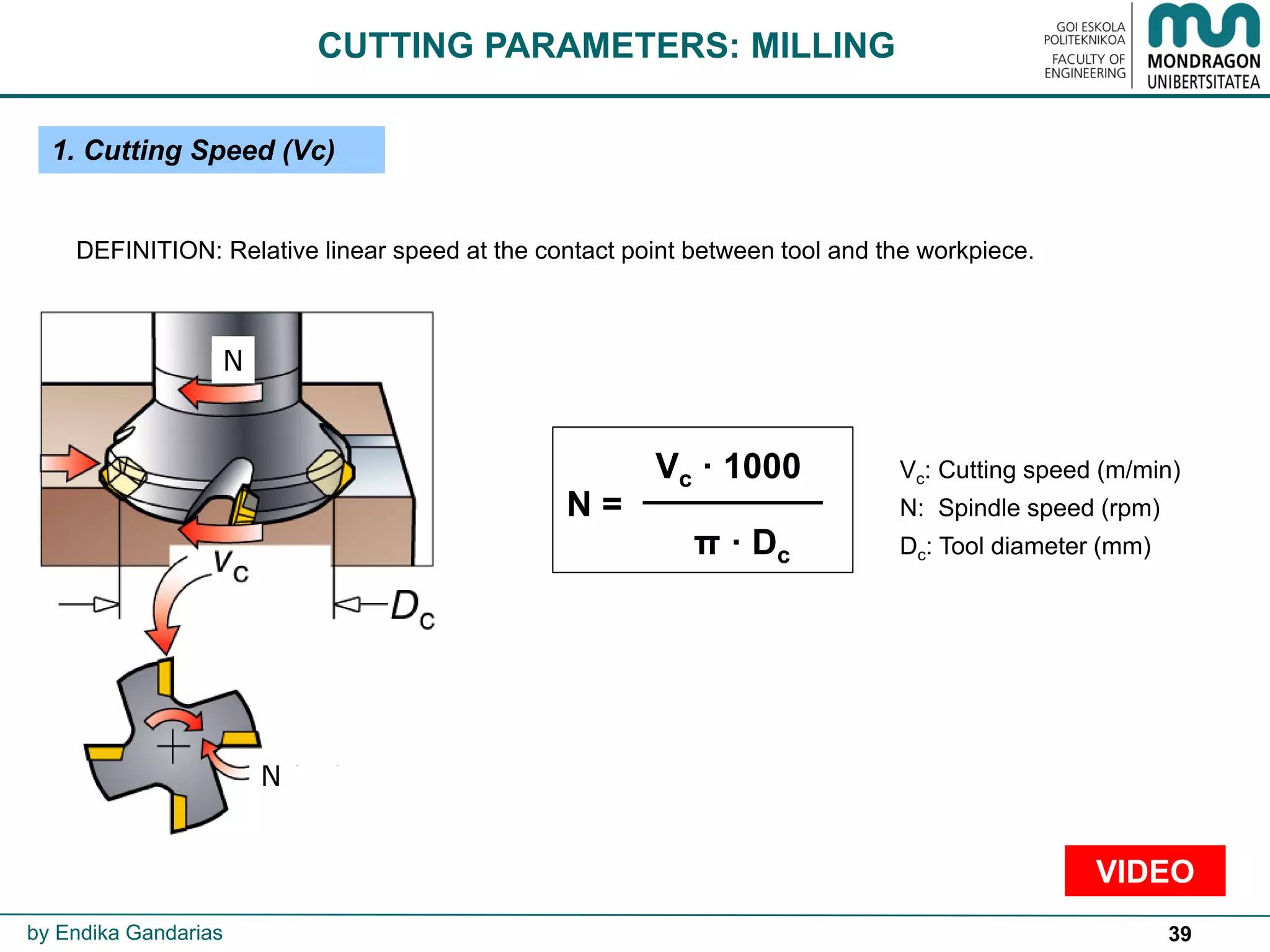

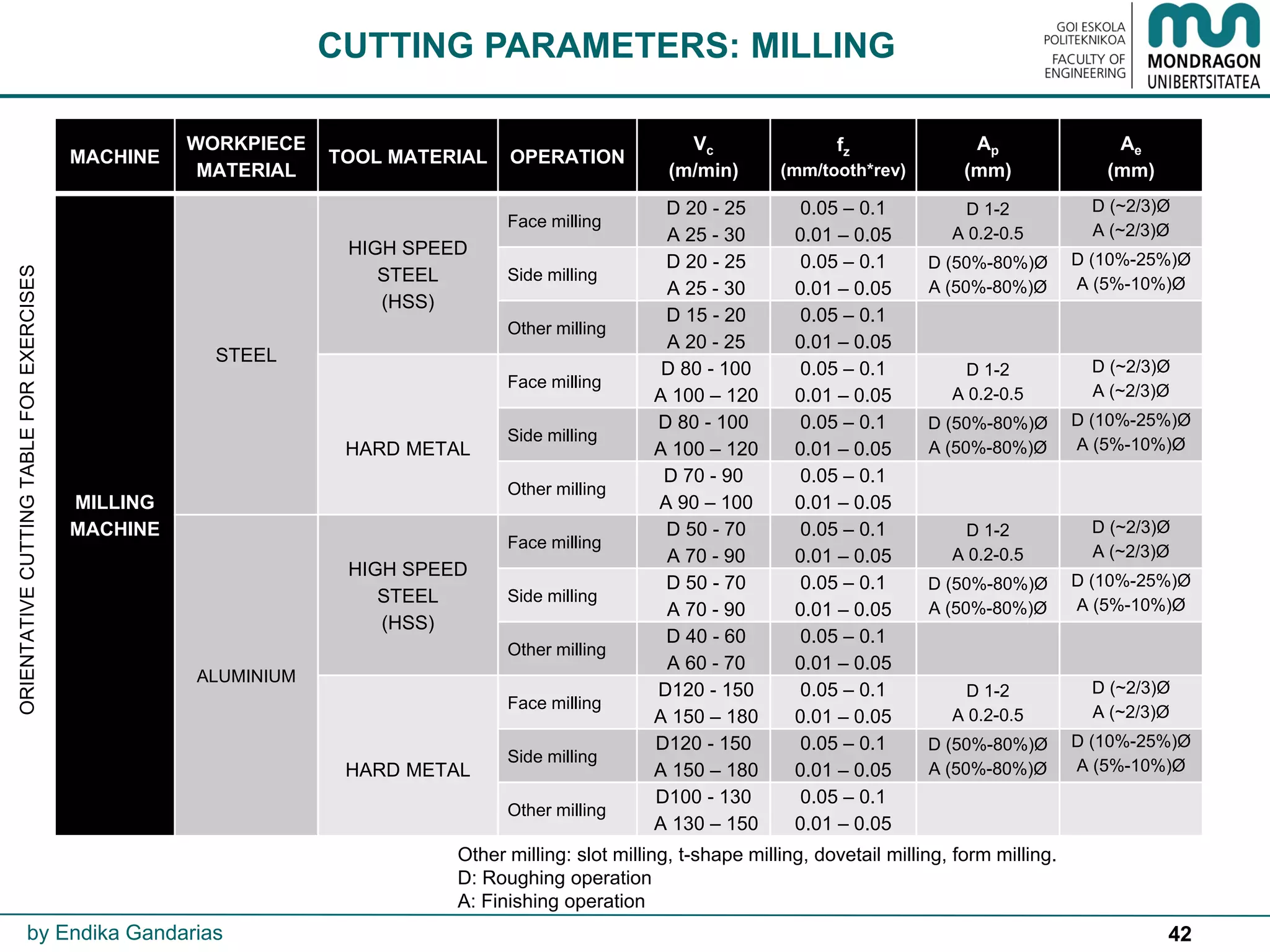

CUTTING PARAMETERS: TURNING

FEED RATE

or

FEED PER MINUTE

by Endika Gandarias

F

ap

ap

ap](https://image.slidesharecdn.com/5cuttingconditions-170204214000/75/Cutting-conditions-33-2048.jpg)

![58

2. Feed

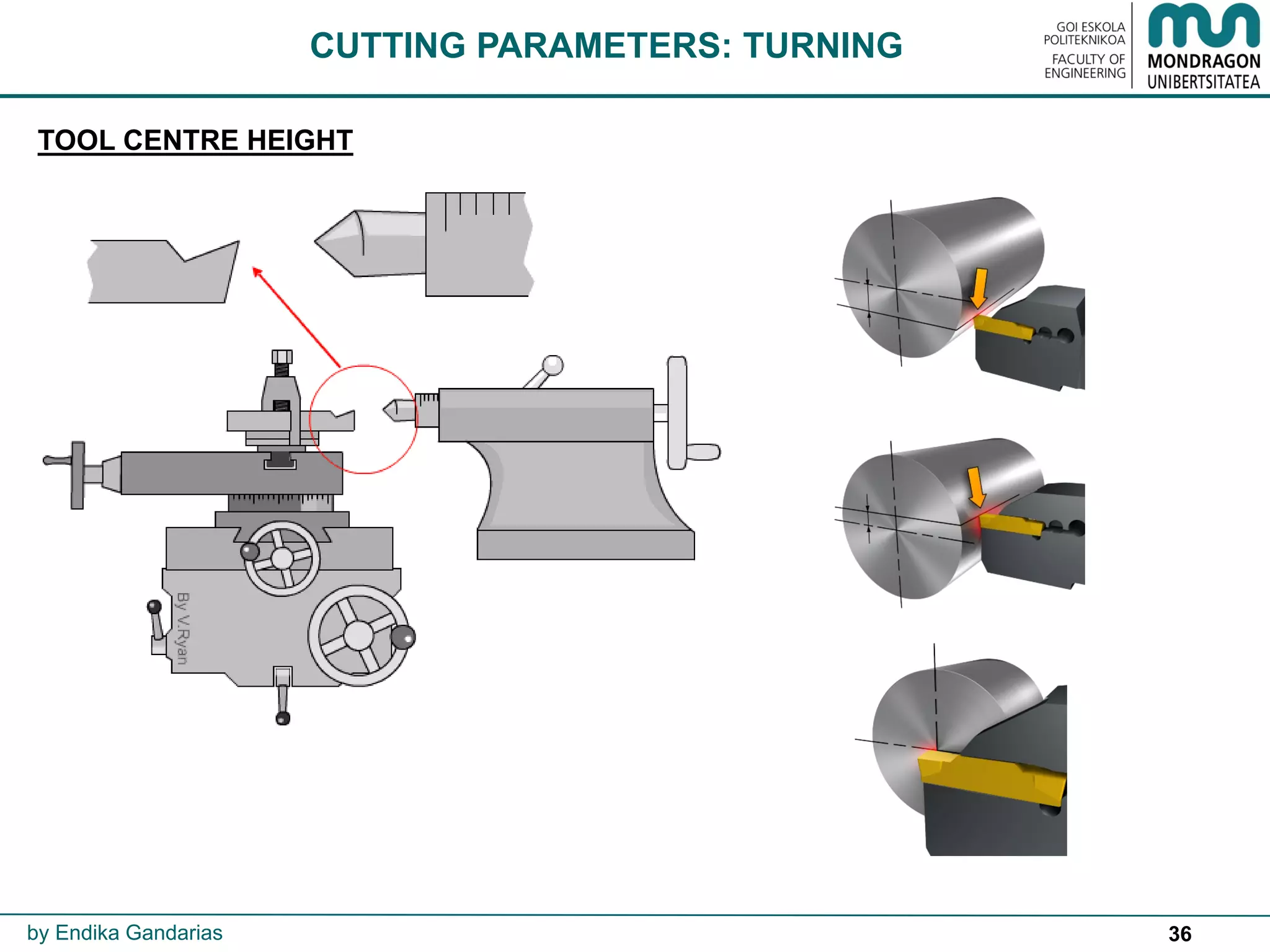

DEFINITION: Relative movement between the workpiece and the tool.

IN

DRILLING

FEED PER

REVOLUTION

(fn)

→

3. Cutting depth (ap)

F [mm/min]

FEED RATE

or

FEED PER MINUTE F = fn·N

CUTTING PARAMETERS: DRILLING

by Endika Gandarias

ap

VIDEO](https://image.slidesharecdn.com/5cuttingconditions-170204214000/75/Cutting-conditions-58-2048.jpg)

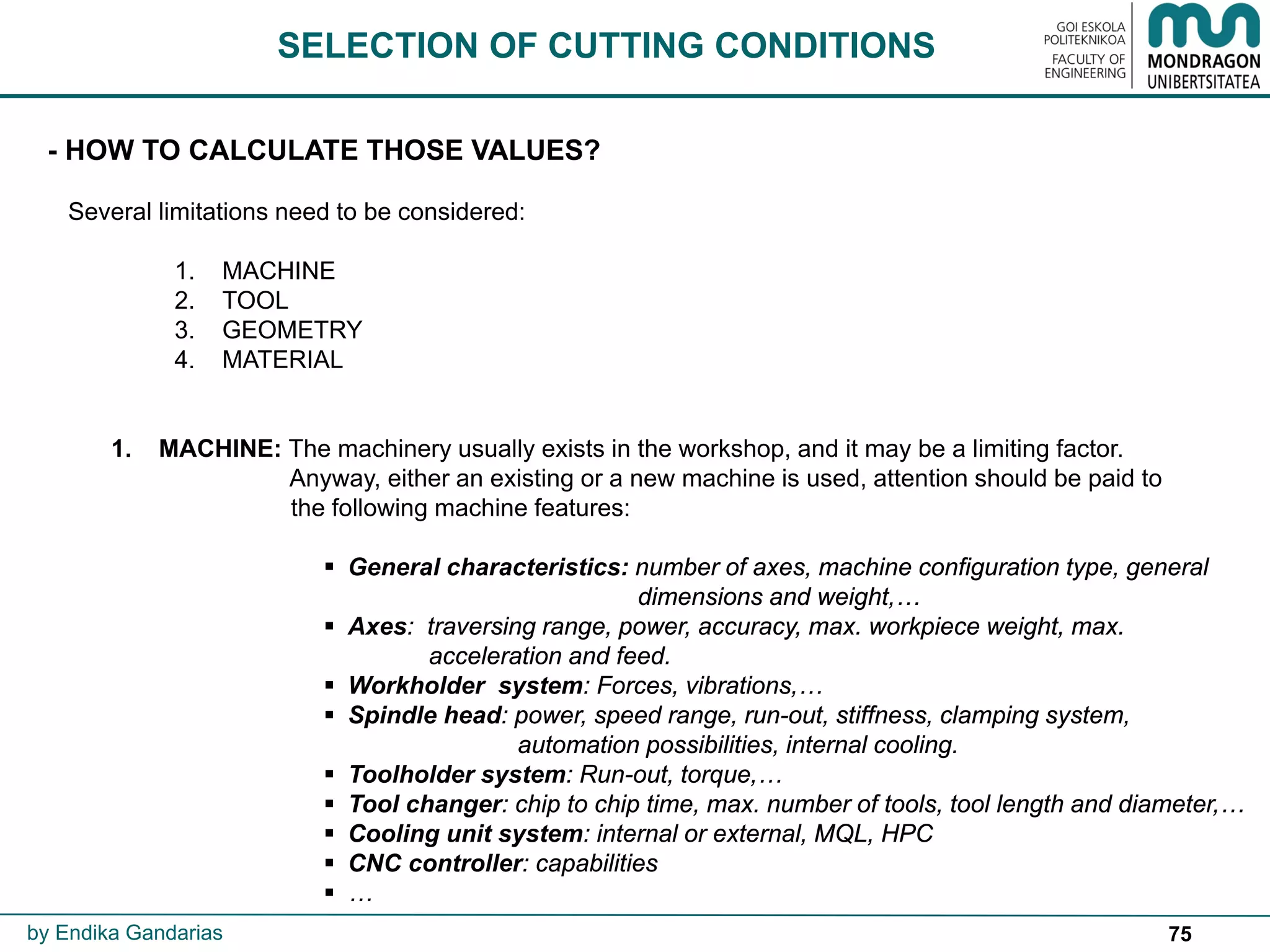

![80

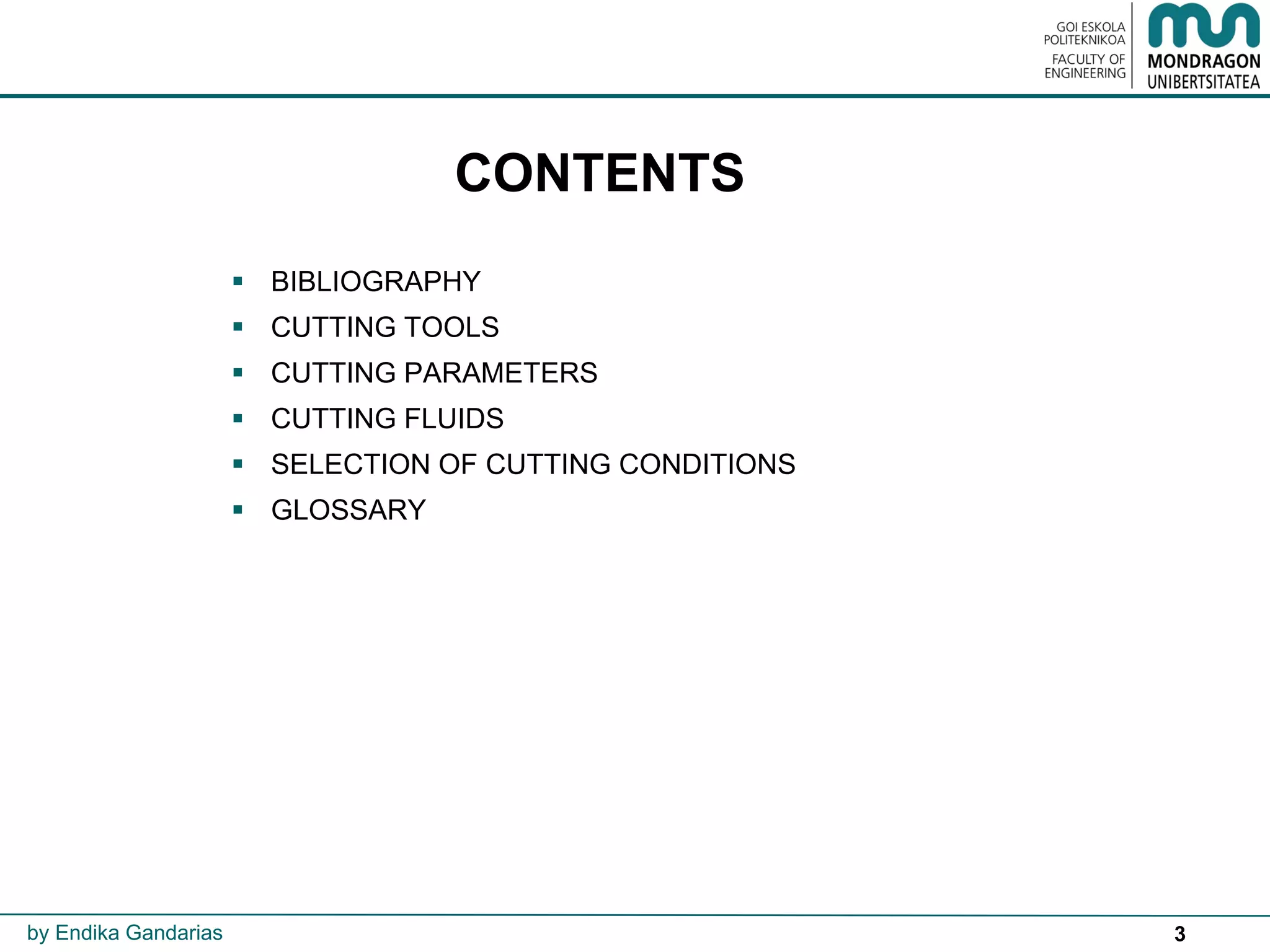

SELECTION OF CUTTING CONDITIONS

3. GEOMETRY: Part geometry will define:

Dimensional tolerances, expected surface roughness values and geometrical

tolerances to be obtained.

Process limitations such as vibration, chatter,…

Tool geometry will be chosen according to the process operations to be accomplished.

4. MATERIAL: Tool-workpiece material combination is very important.

According to that, tool manufacturers usually offer customers cutting condition tables for

free. These tables are the result of many experiments carried out.

Usually these values correspond to a tool life of 15 minutes and should be regarded as

starting values. They are obtained according to Taylor’s equation.

Taylor’s Tool life formula: Vc * Tn = C

Expanded Taylor`s Tool life formula: Vc * Tn * fn

a * ap

b = C

Vc : Cutting speed [m/min]

fn : Feed per revolution [mm/rev]

ap : Cutting depth [mm]

T : Tool life [min]

a, b, n, C: Constants

by Endika Gandarias

VIDEO](https://image.slidesharecdn.com/5cuttingconditions-170204214000/75/Cutting-conditions-80-2048.jpg)