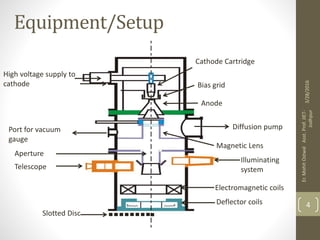

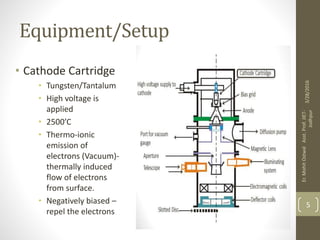

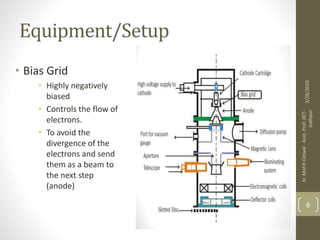

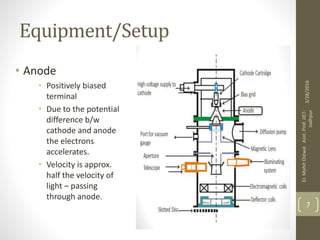

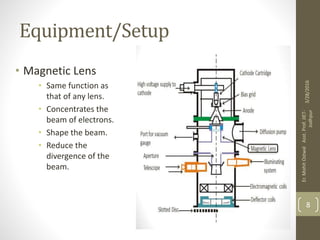

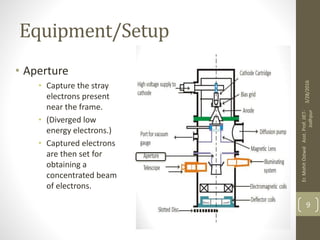

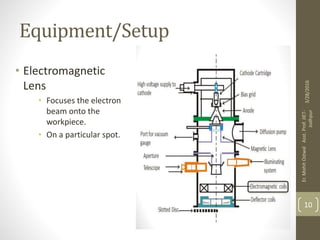

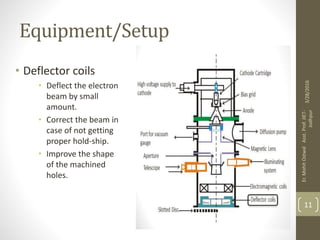

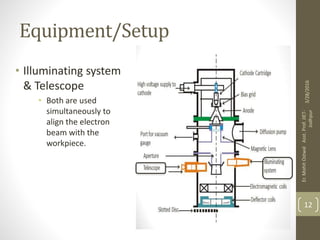

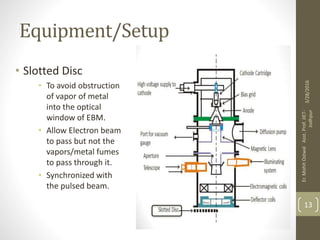

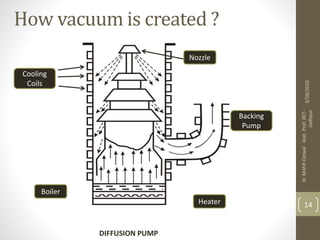

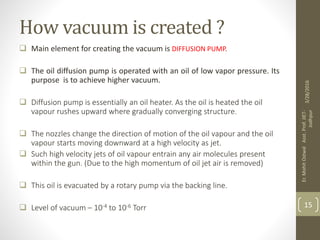

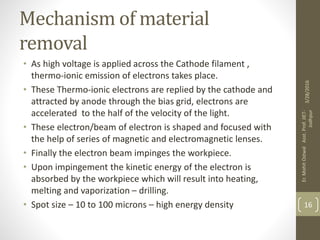

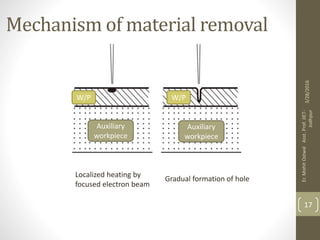

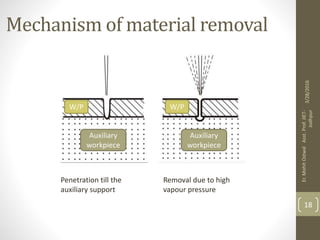

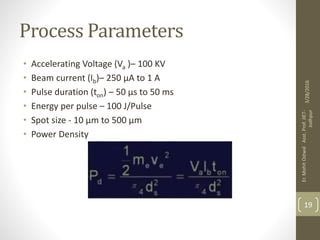

Electron beam machining (EBM) utilizes a focused beam of high-velocity electrons to perform high-speed drilling and cutting. It works by melting and rapidly vaporizing material through intense heating caused by bombarding electrons. The process requires vacuum and uses a cathode, magnetic lenses, and other equipment to generate and focus the electron beam. EBM can drill small, high aspect ratio holes in almost any material without mechanical forces. It has high material removal rates but also high equipment costs and non-productive pump down times. Applications include drilling, sheet perforation, and circuit pattern generation.