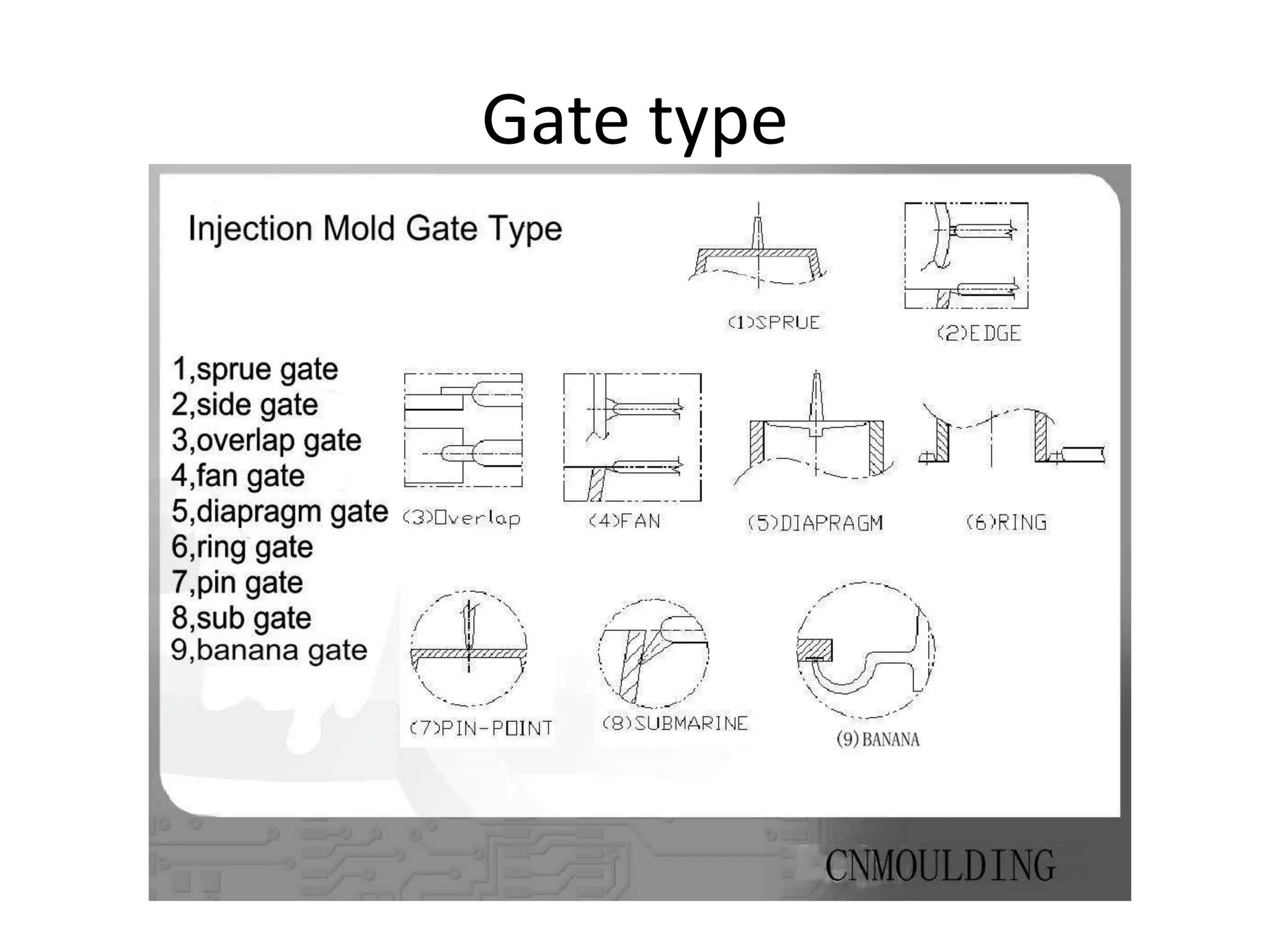

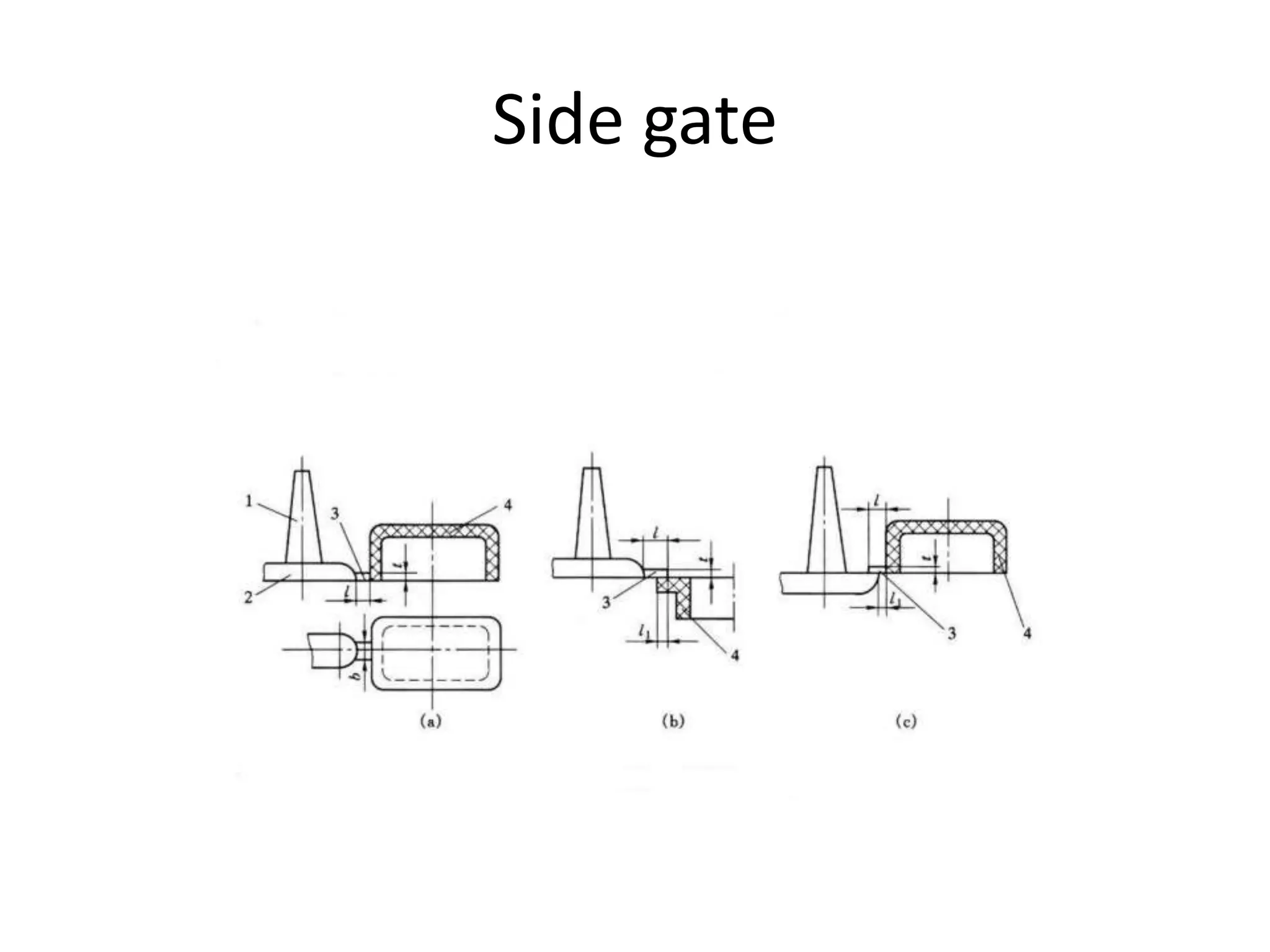

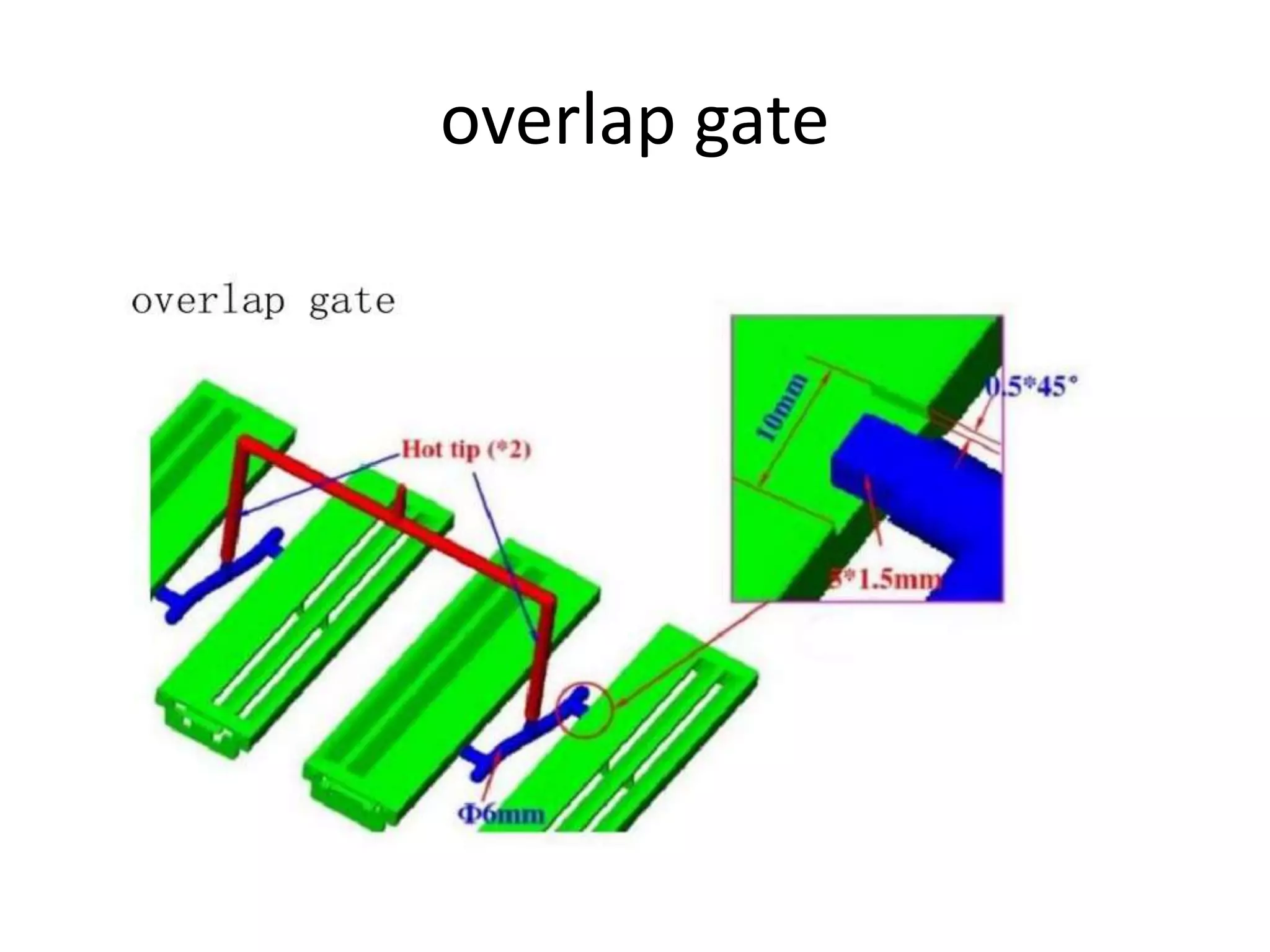

The document describes various types of injection mold gates used in plastic molding, distinguishing between large and small gates based on their cross-sectional dimensions and effects on filling flow. Large gates, which are unrestricted, facilitate material and pressure transmission but can cause flow back, while small gates, or restrictive gates, significantly impact filling speed and can lead to defects if not sized correctly. Specific applications for different gate types are also outlined, such as sprue gates for deep parts and fan gates for thin-film products.