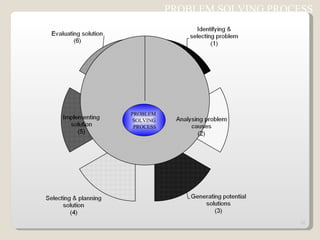

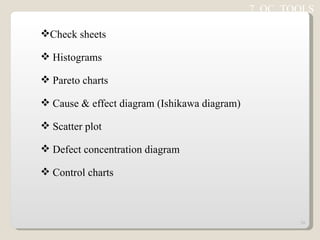

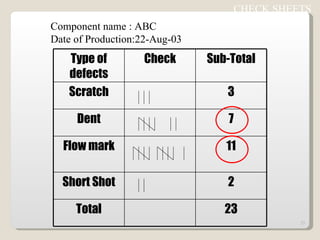

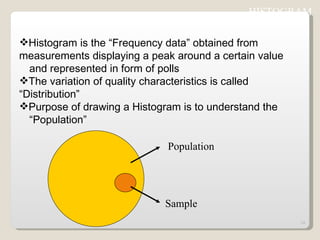

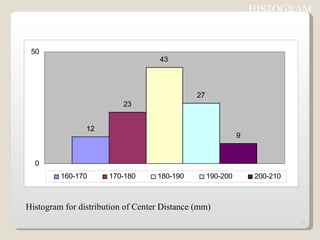

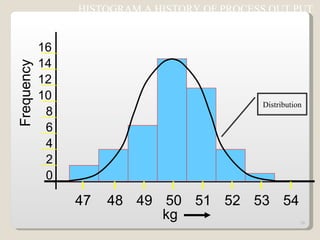

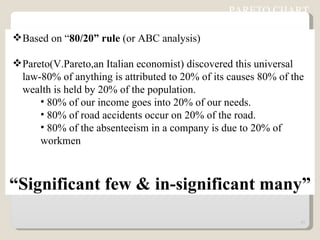

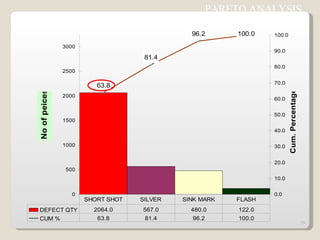

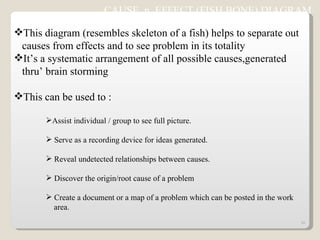

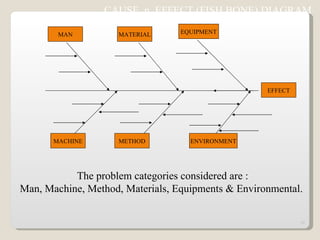

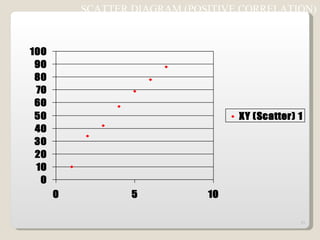

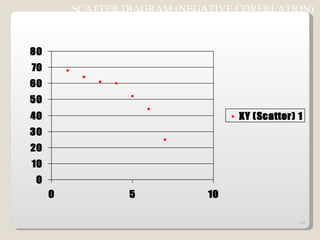

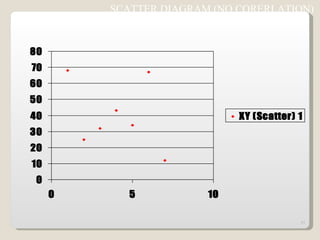

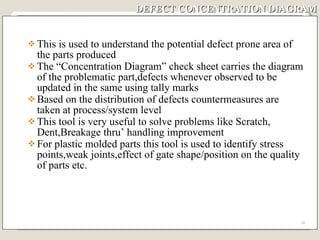

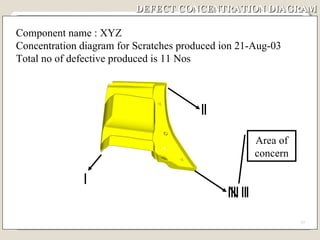

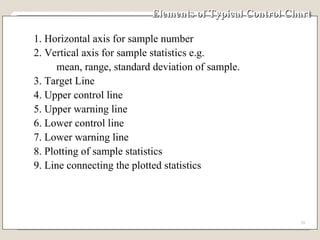

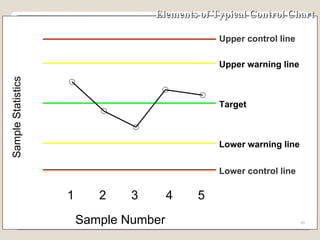

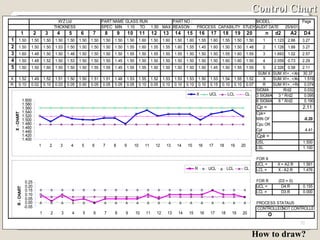

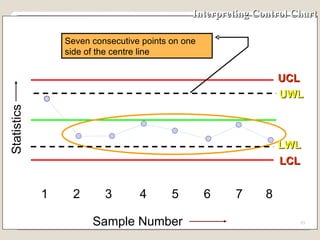

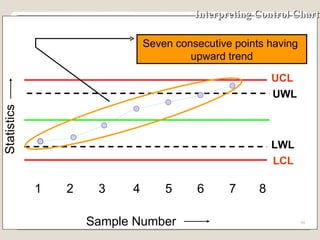

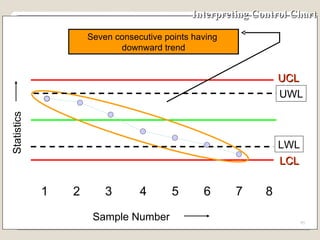

The document discusses 7 quality control tools used to identify, analyze, and resolve problems in a systematic manner. The tools include check sheets, histograms, Pareto charts, cause-and-effect diagrams, scatter plots, defect concentration diagrams, and control charts. These simple but powerful tools can help solve day-to-day work problems and identify solutions by collecting and analyzing process data.