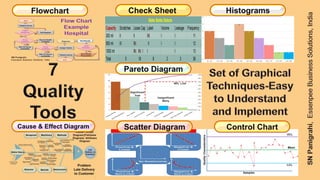

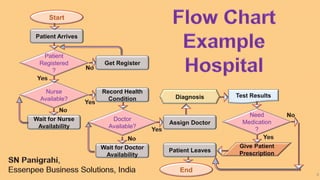

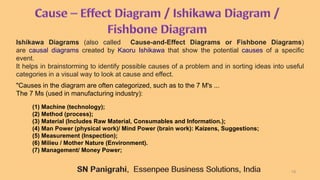

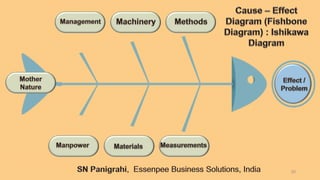

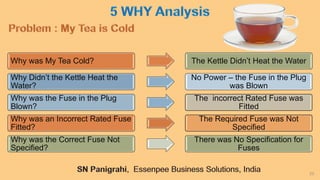

SN Panigrahi is a seasoned expert in project management, supply chain, and quality control, with 30 years of experience as a corporate trainer, author, and speaker. He emphasizes the importance and usability of seven quality control tools, including flowcharts and control charts, in enhancing process and product quality. His extensive background includes certifications in PMP, Lean Six Sigma, and GST, along with contributions in workshops, articles, and various public forums.