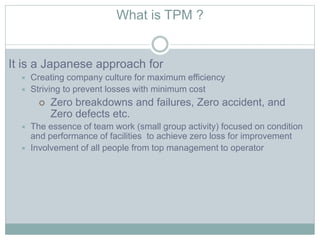

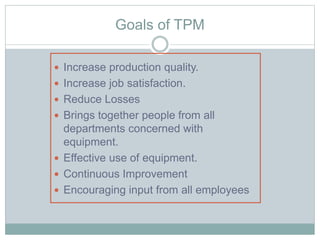

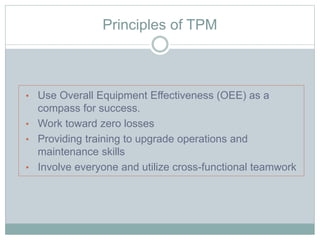

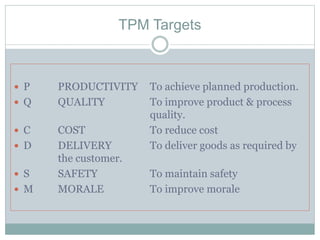

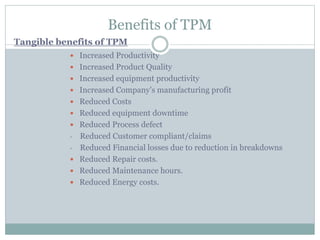

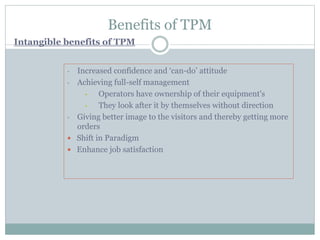

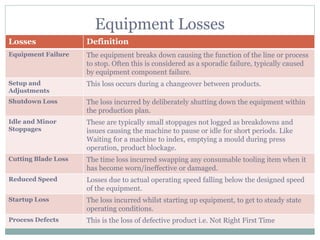

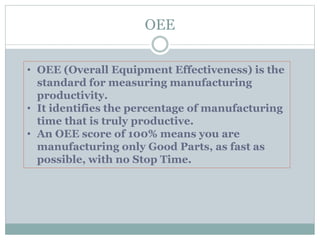

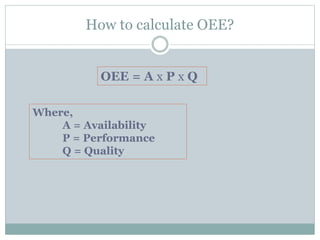

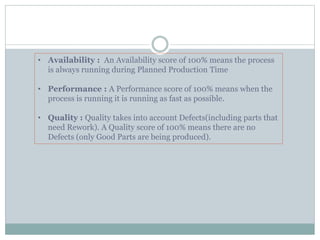

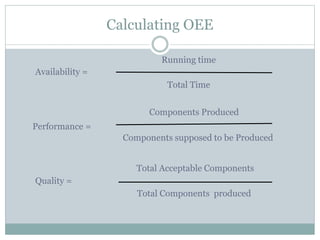

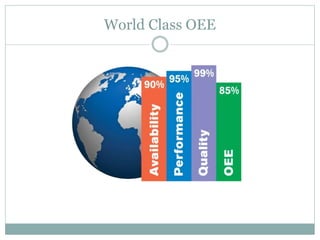

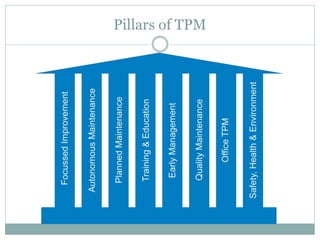

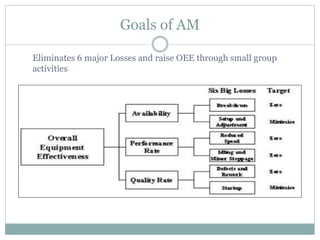

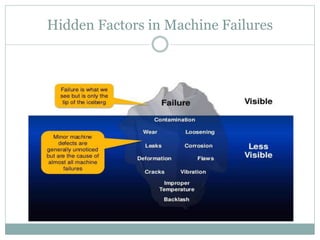

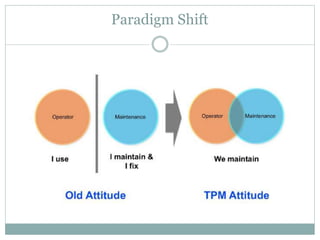

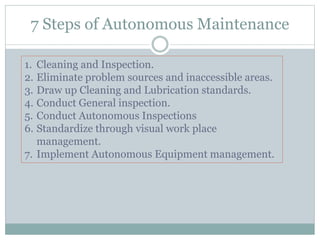

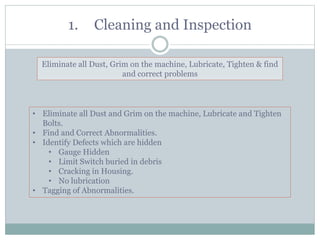

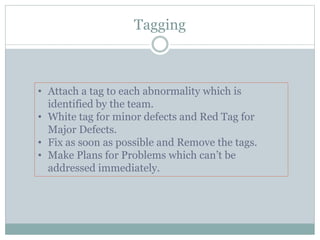

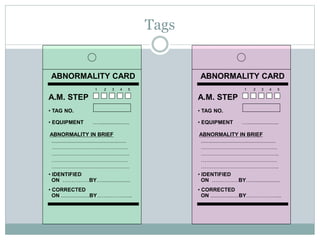

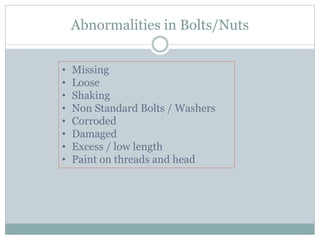

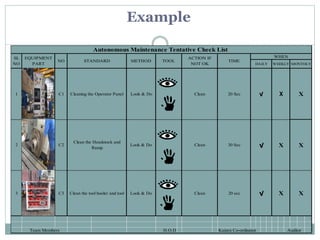

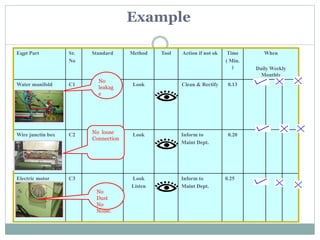

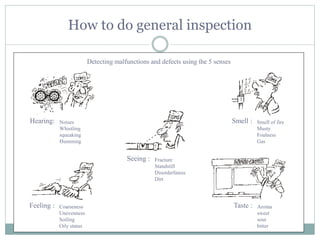

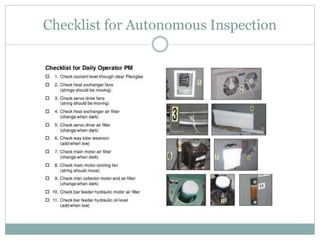

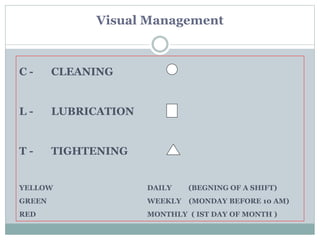

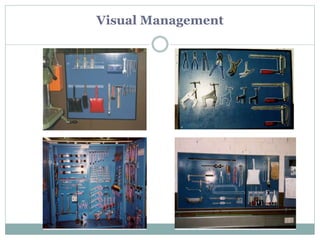

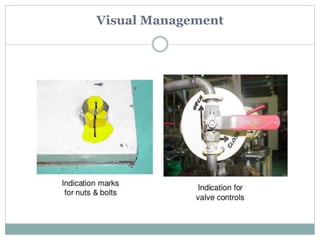

TPM (Total Productive Maintenance) is a Japanese approach to equipment maintenance that focuses on minimizing breakdowns and maximizing equipment efficiency. It involves operators performing basic cleaning and inspections of equipment on a daily basis through autonomous maintenance. The goals of TPM and autonomous maintenance include eliminating equipment losses to improve overall equipment effectiveness (OEE) and increase productivity, quality and profitability through early problem detection and correction. Autonomous maintenance is carried out through a 7 step process that includes cleaning, inspection, identifying abnormalities, and standardizing maintenance procedures.