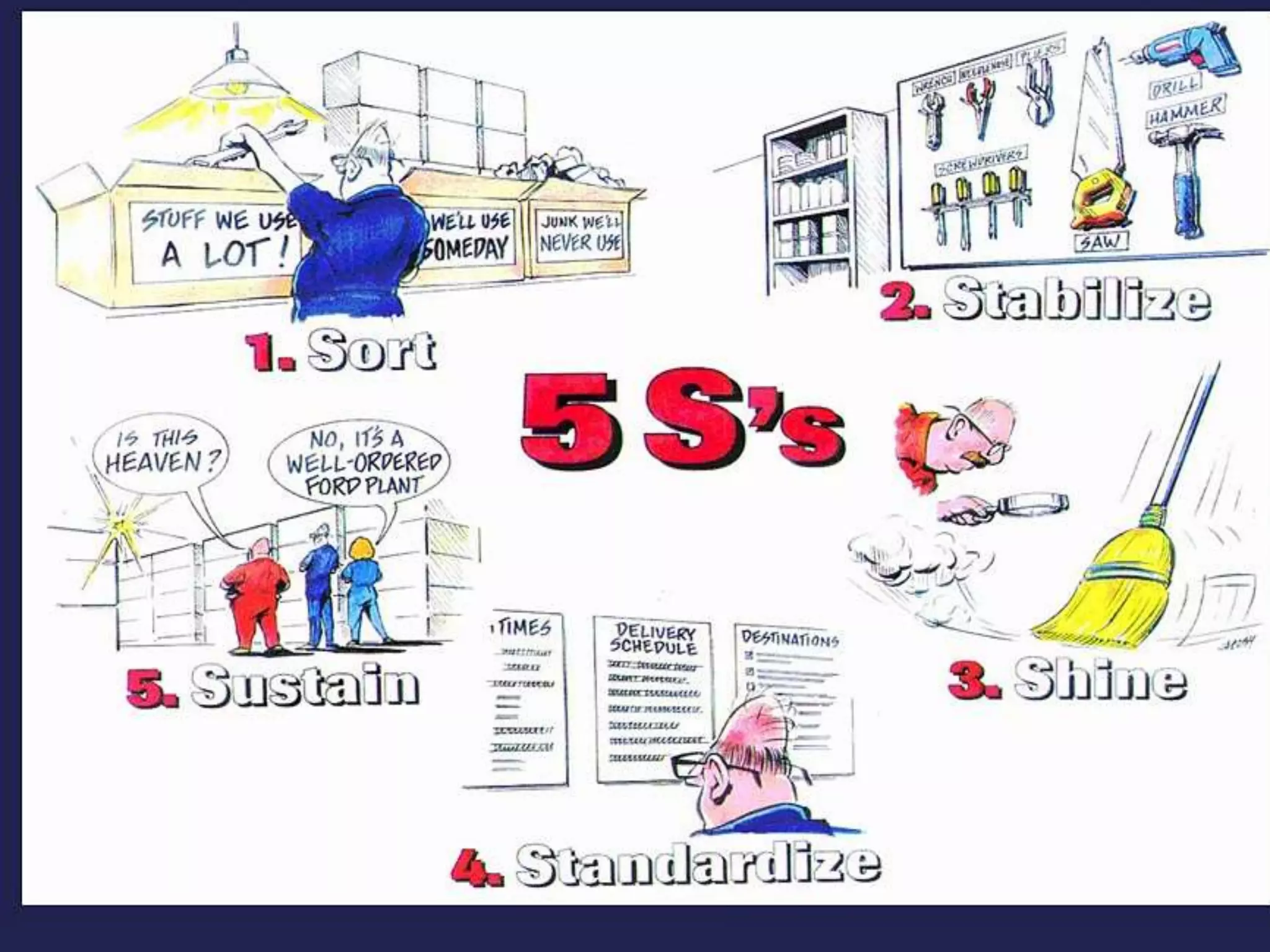

The 5S system is a workplace organization method that involves 5 steps: Sort, Set In Order, Shine, Standardize, and Sustain. The goals of 5S are to reduce waste, improve safety and productivity, and establish standardized work processes. Each step is important for continuous improvement. Sort removes unneeded items. Set In Order organizes the workspace. Shine keeps it clean. Standardize develops processes. Sustain trains employees to maintain the system through discipline and correction. Proper implementation of 5S creates a visual and efficient work environment.