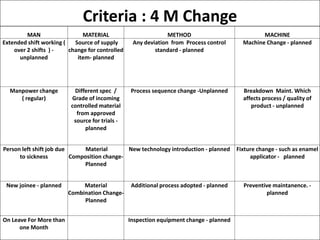

This document discusses 4M change, which refers to changes in man, machine, material, and method. It provides examples of types of changes that fall under each category and describes how 4M changes are classified as either planned or unplanned. The purposes of monitoring 4M changes are to closely track their effects on processes and products. Key criteria for evaluating 4M changes include setting up containment and traceability measures to monitor production and trace any potential problems back to their source.