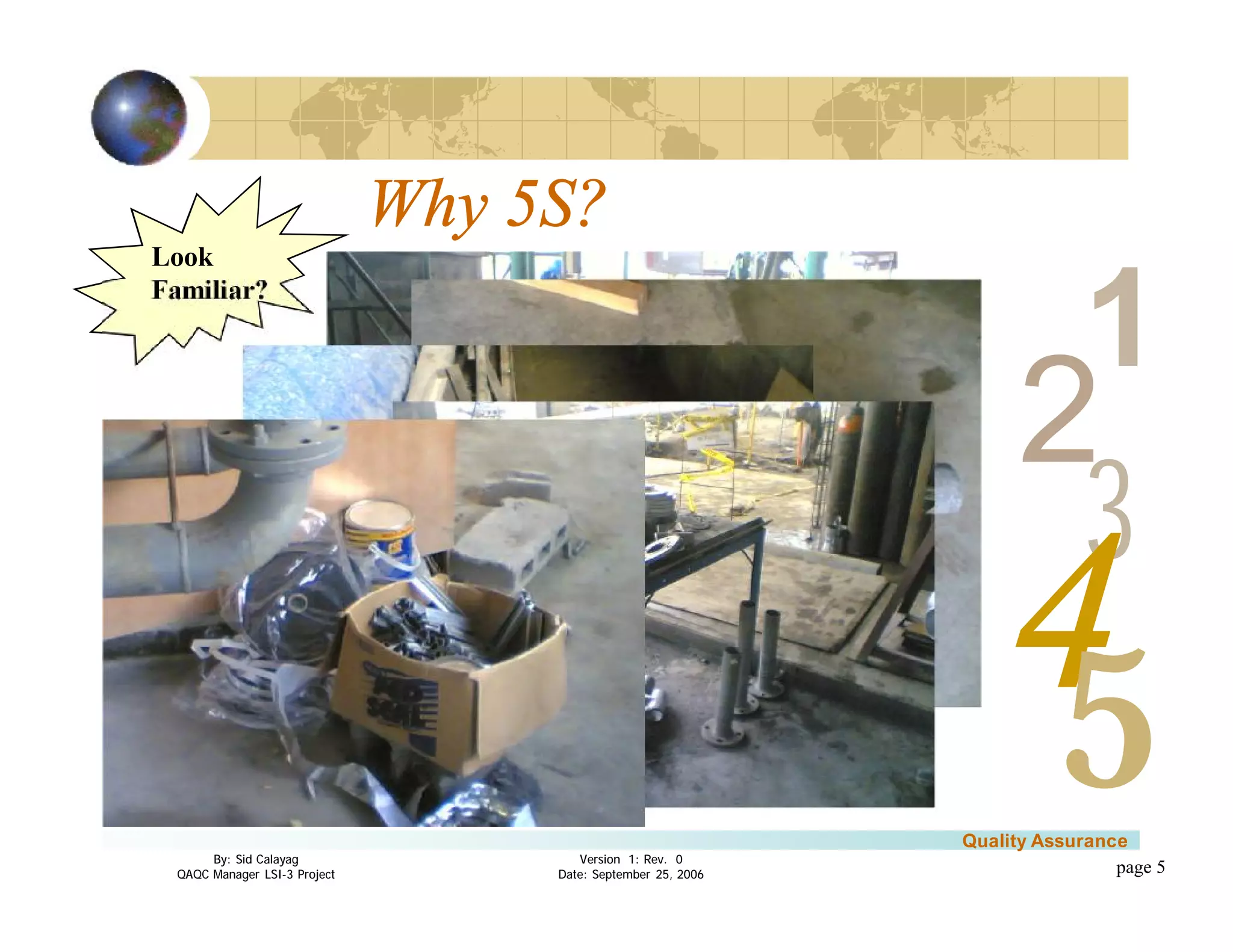

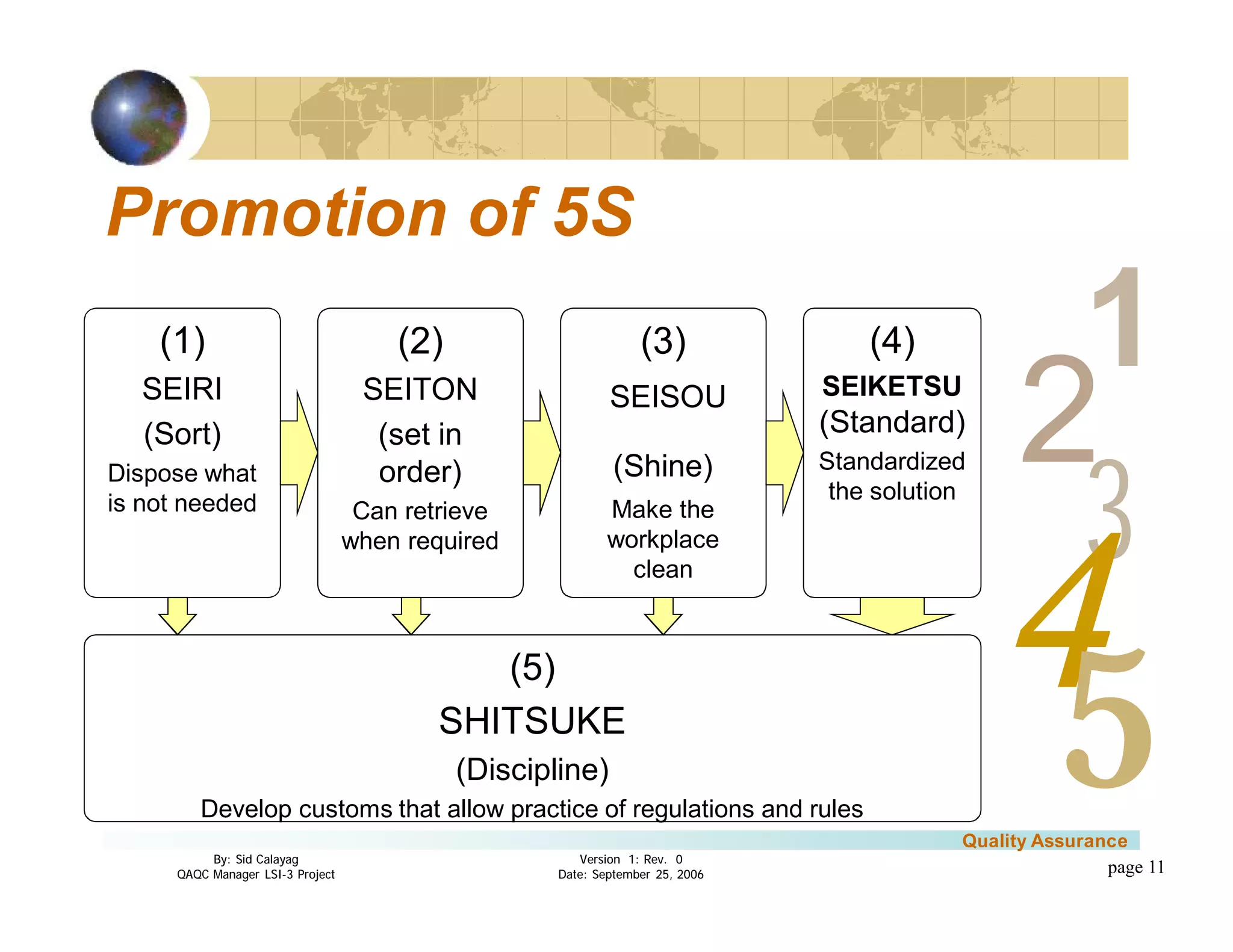

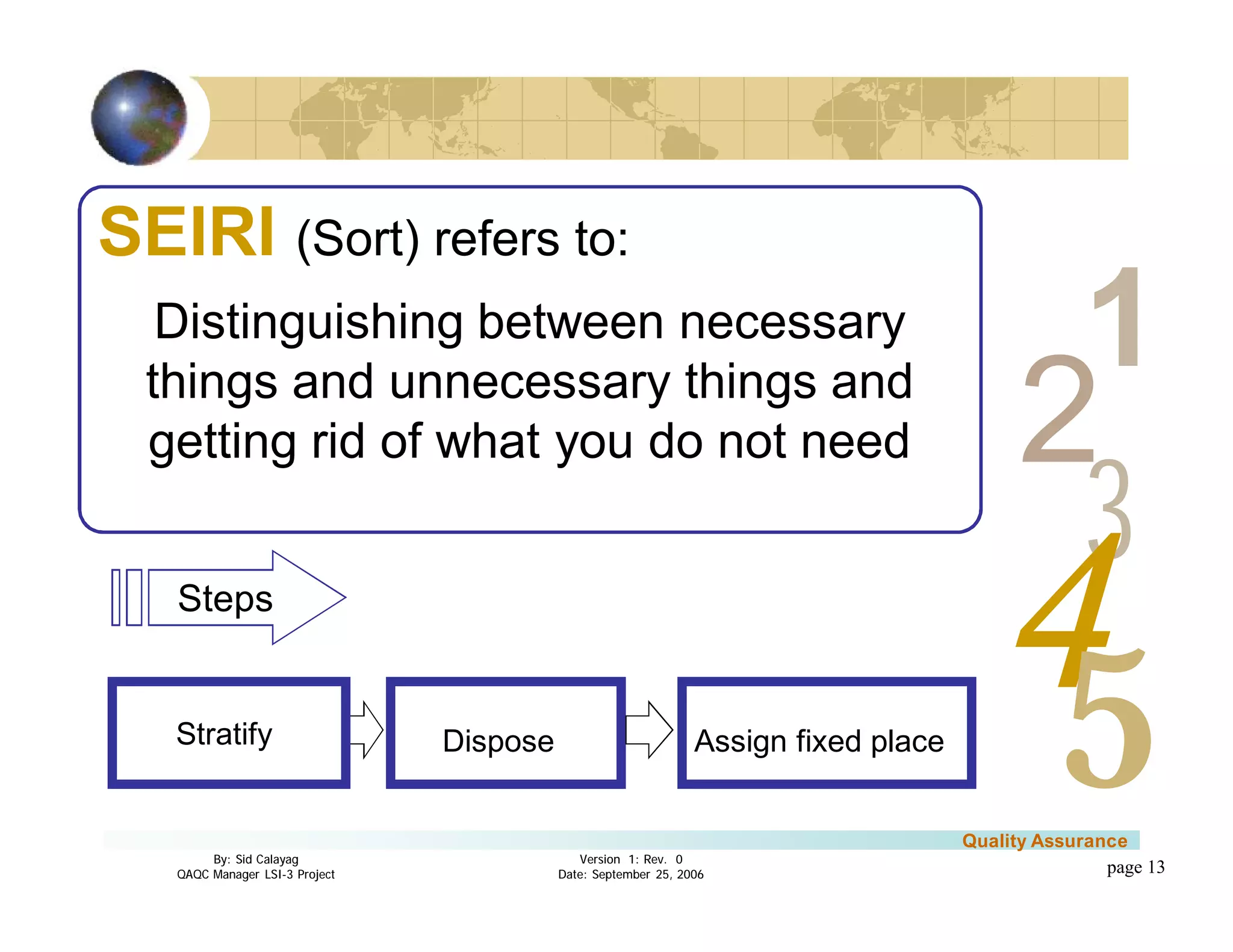

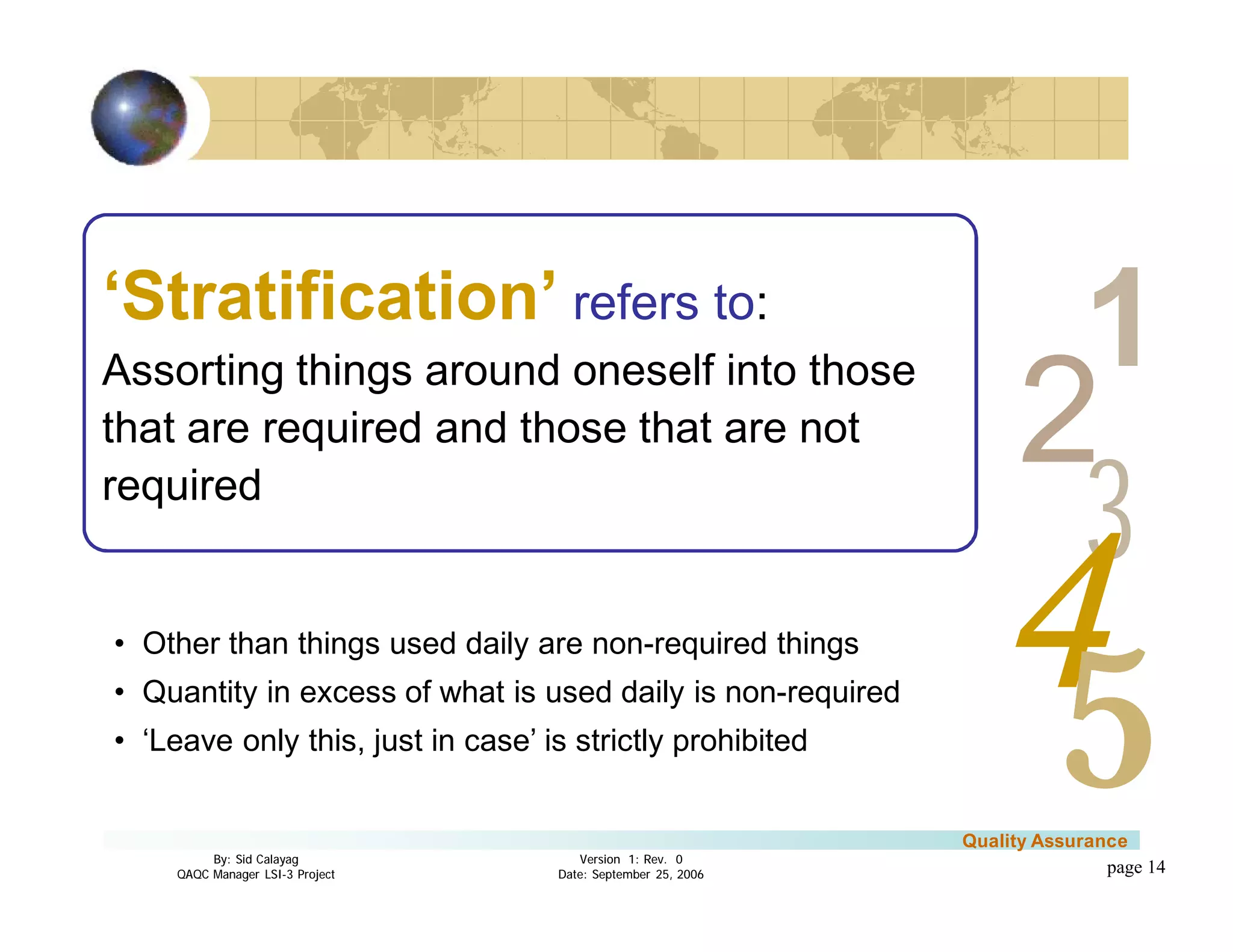

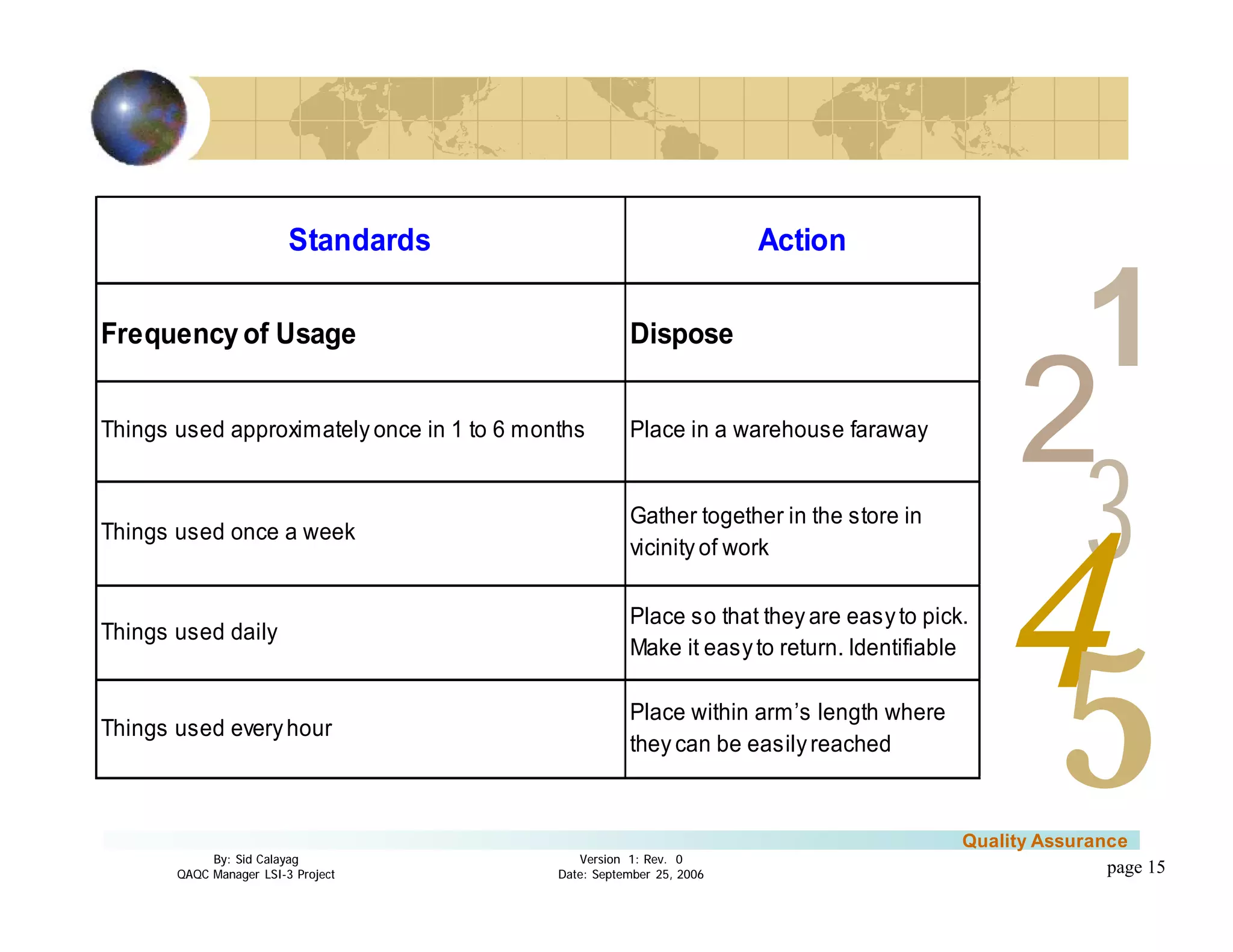

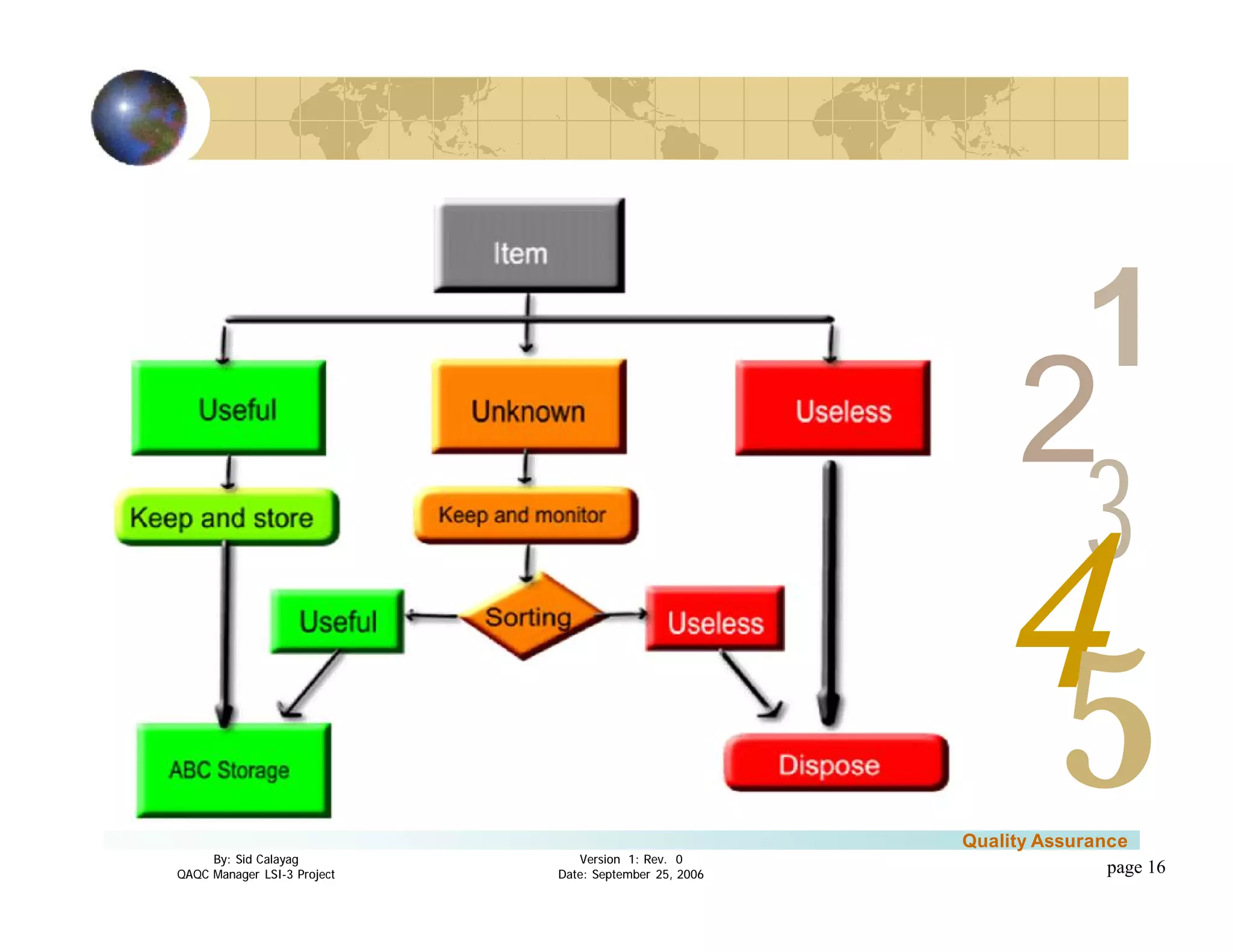

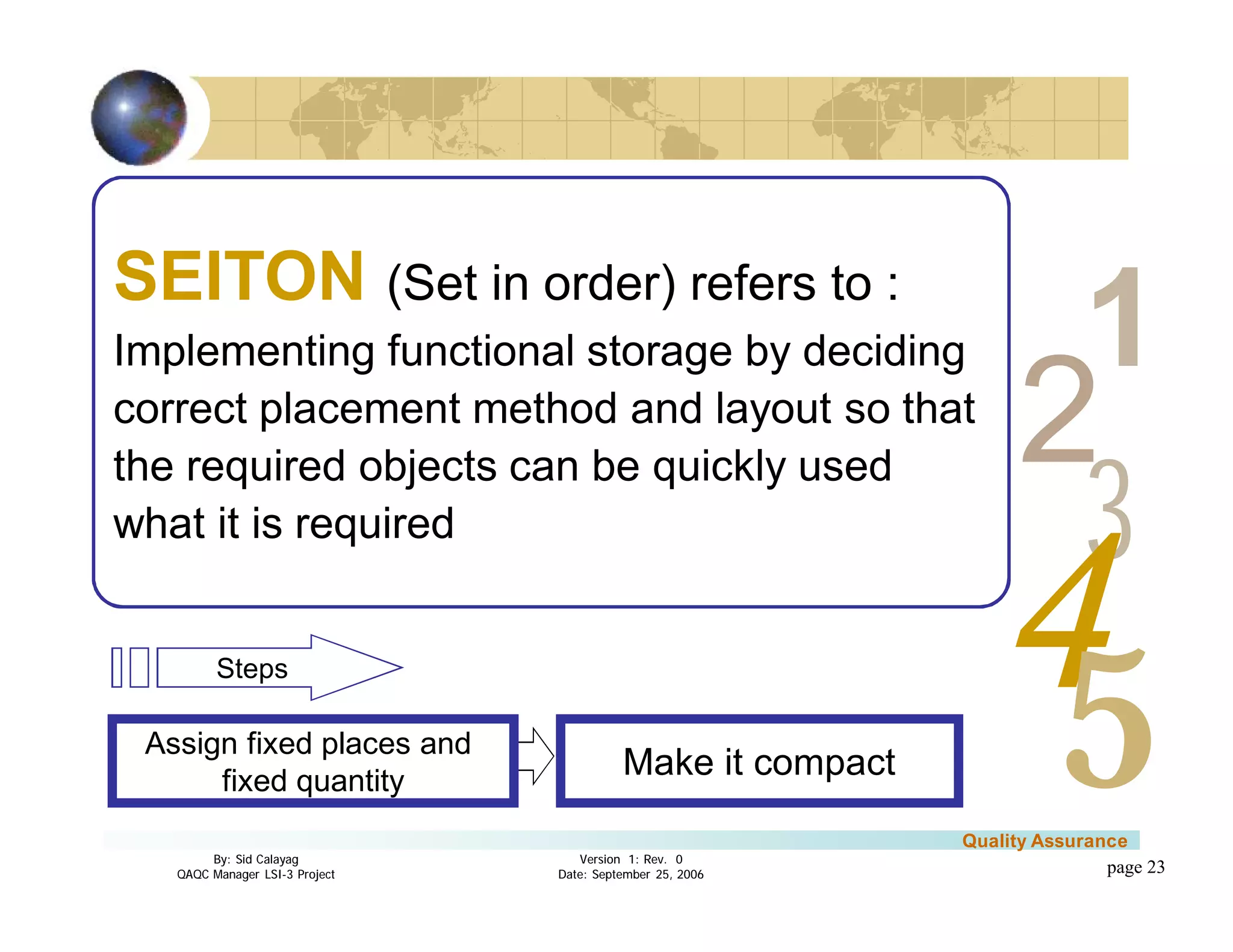

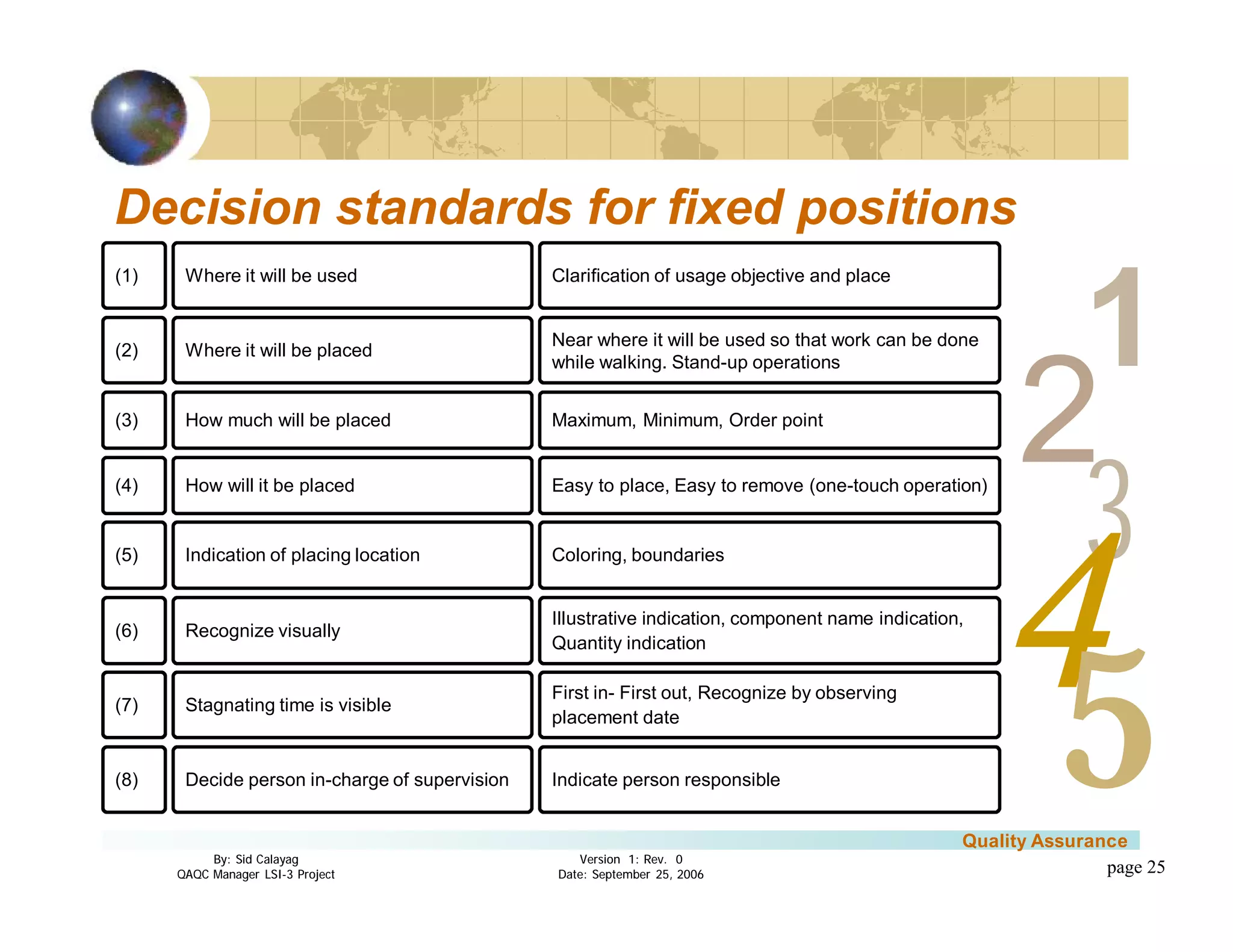

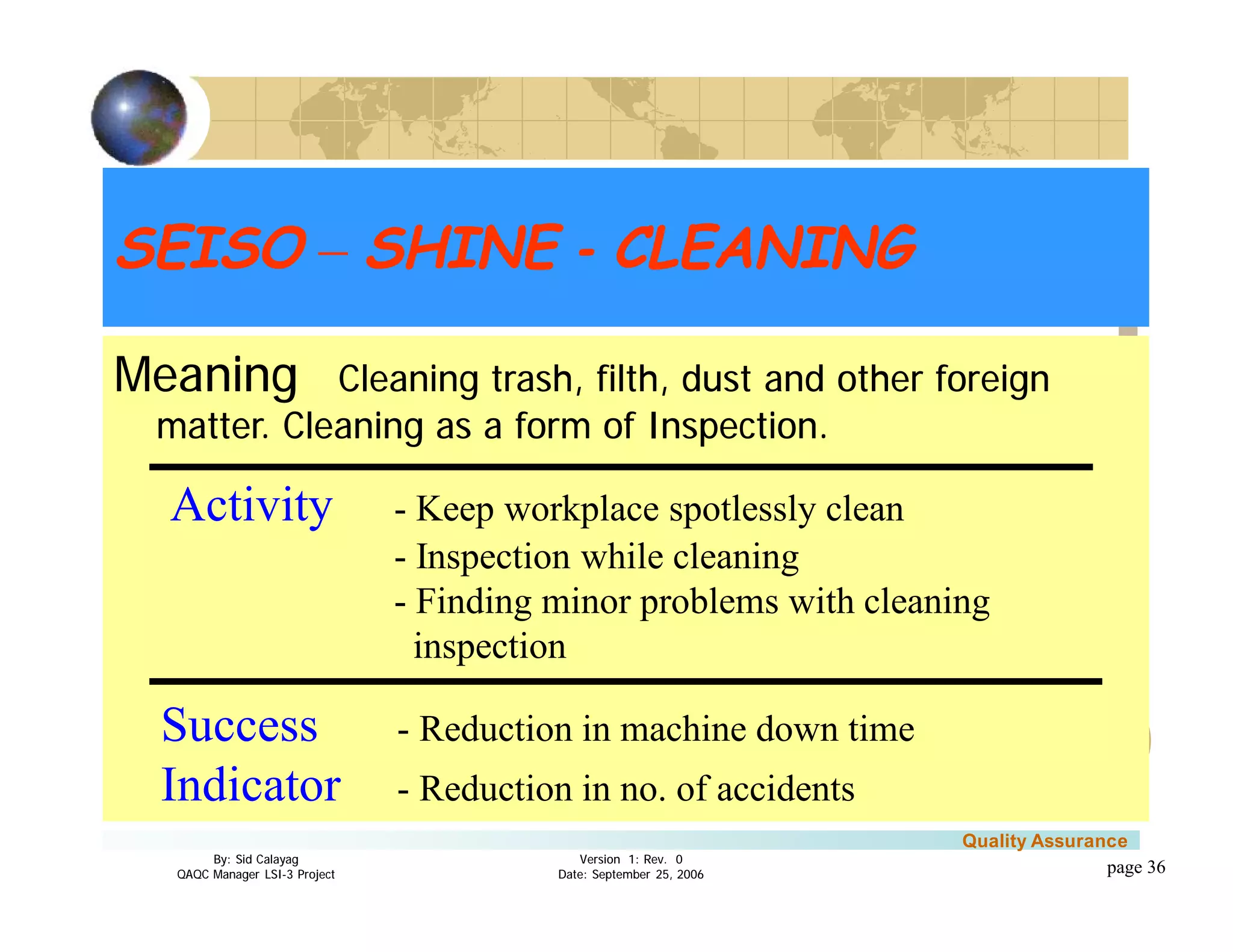

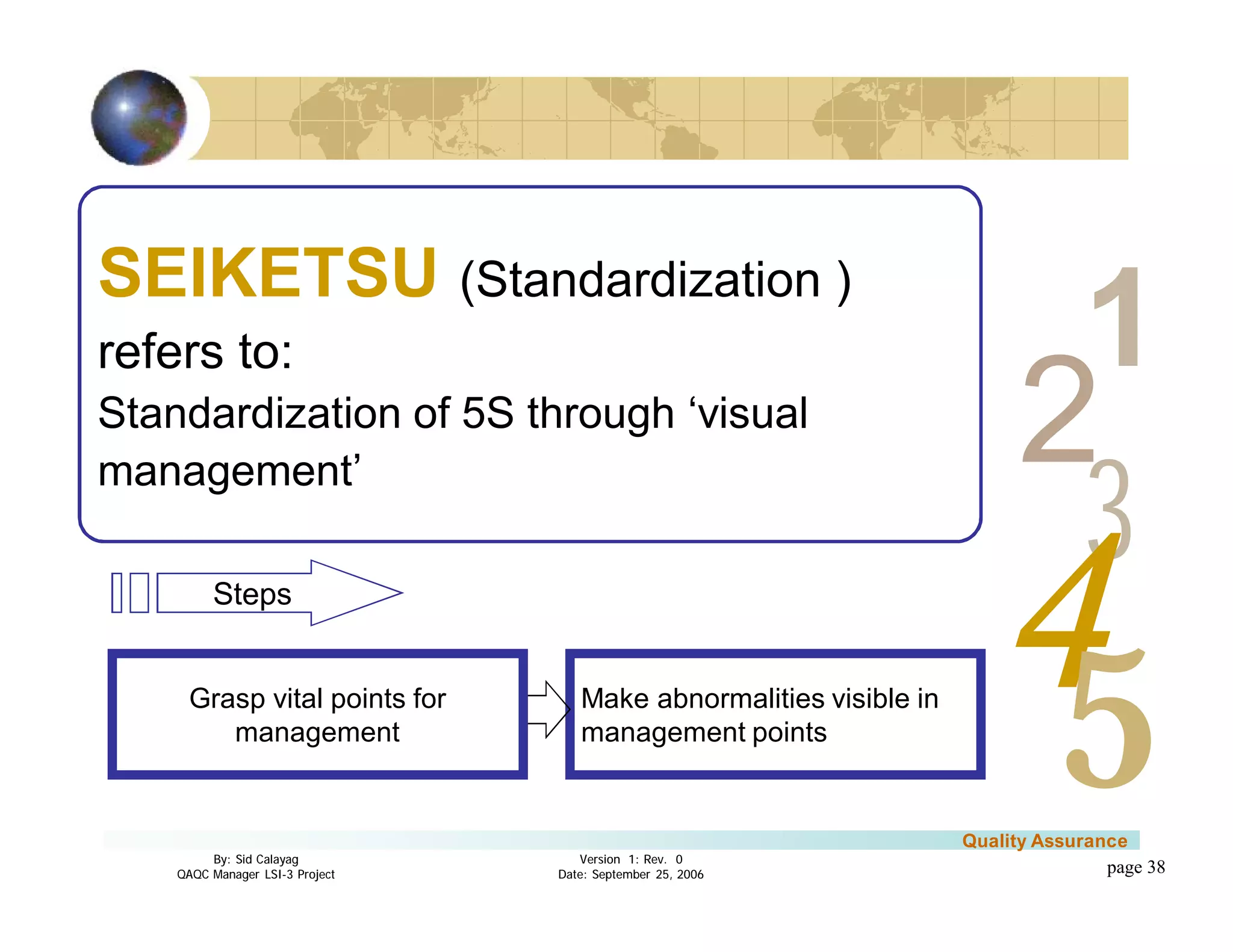

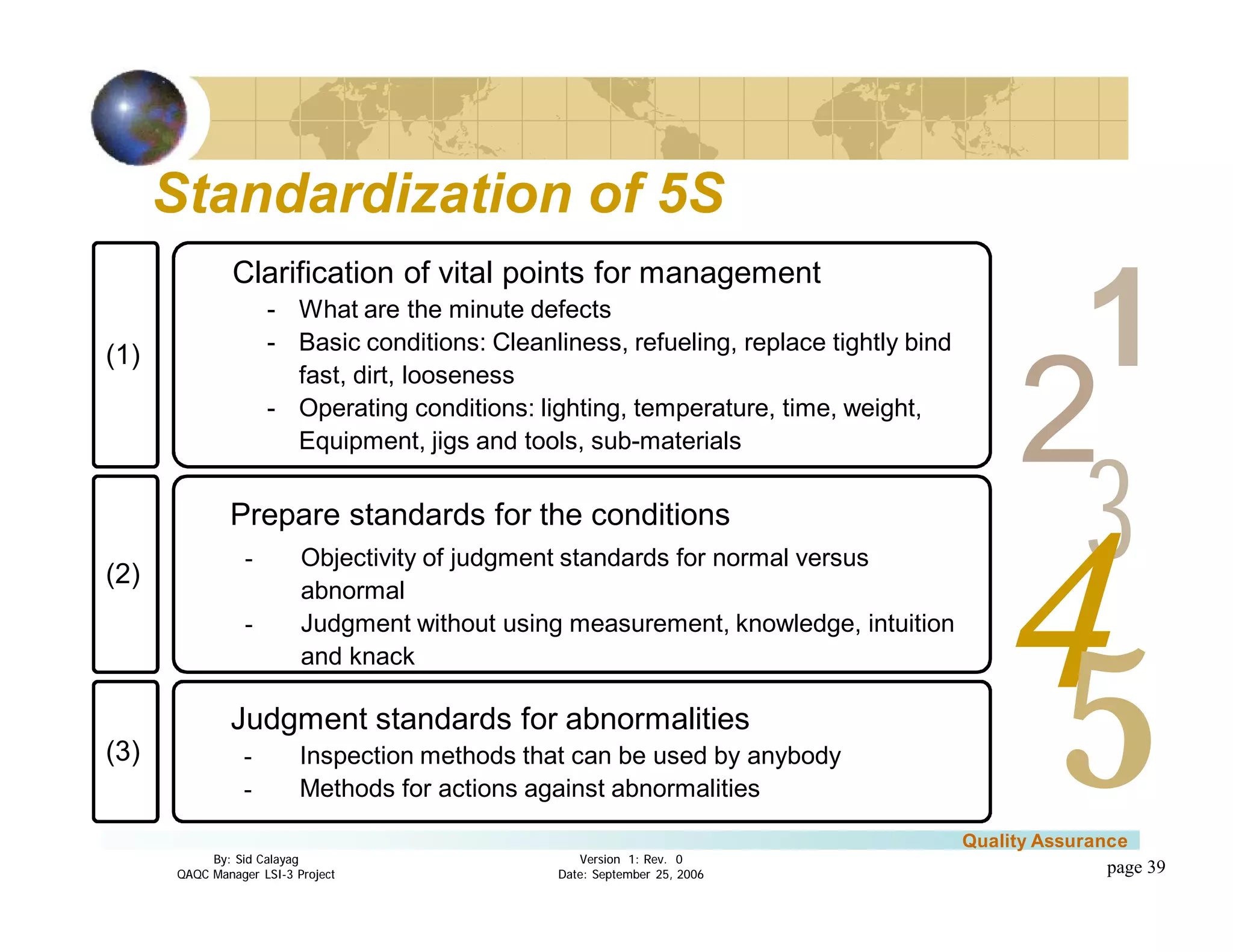

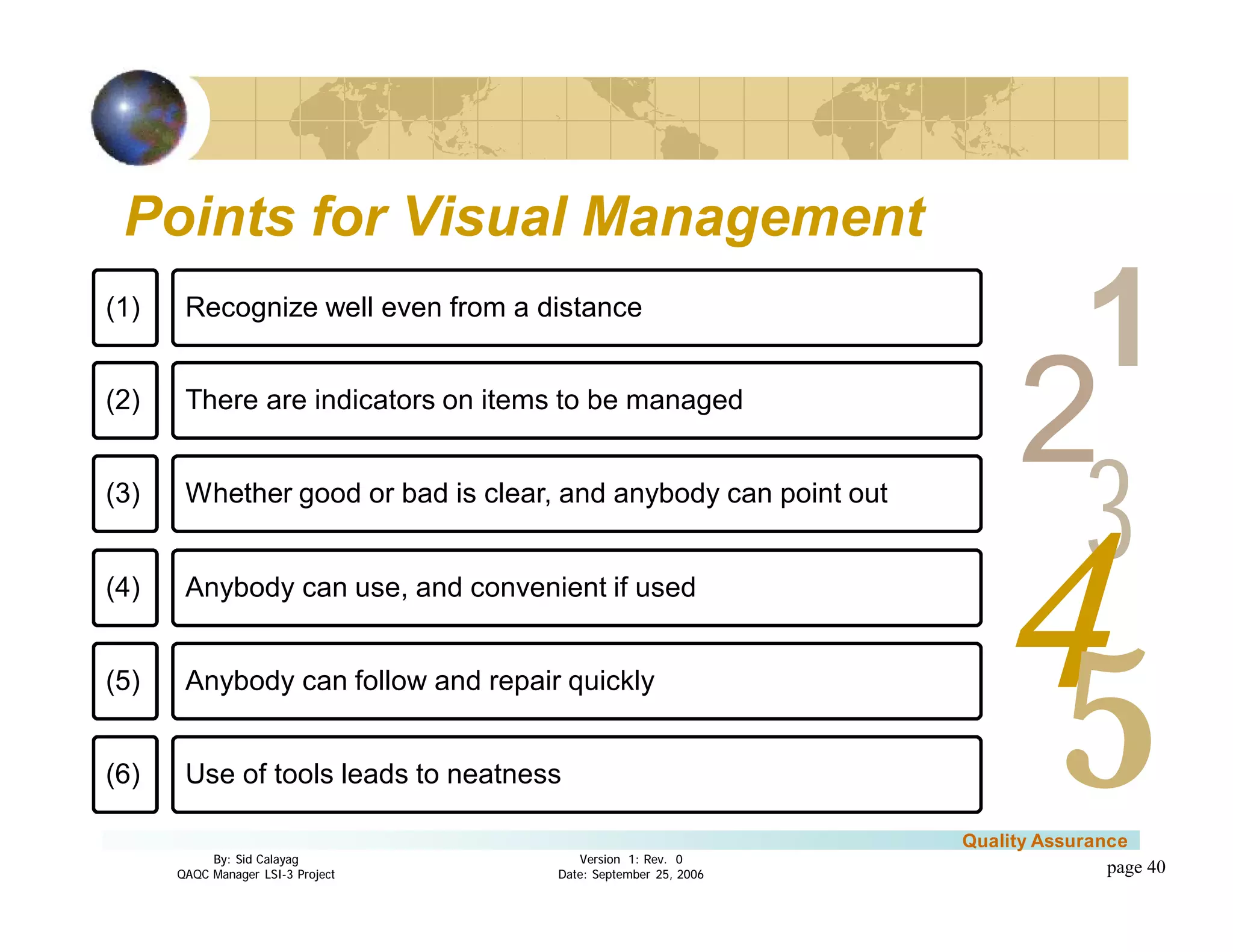

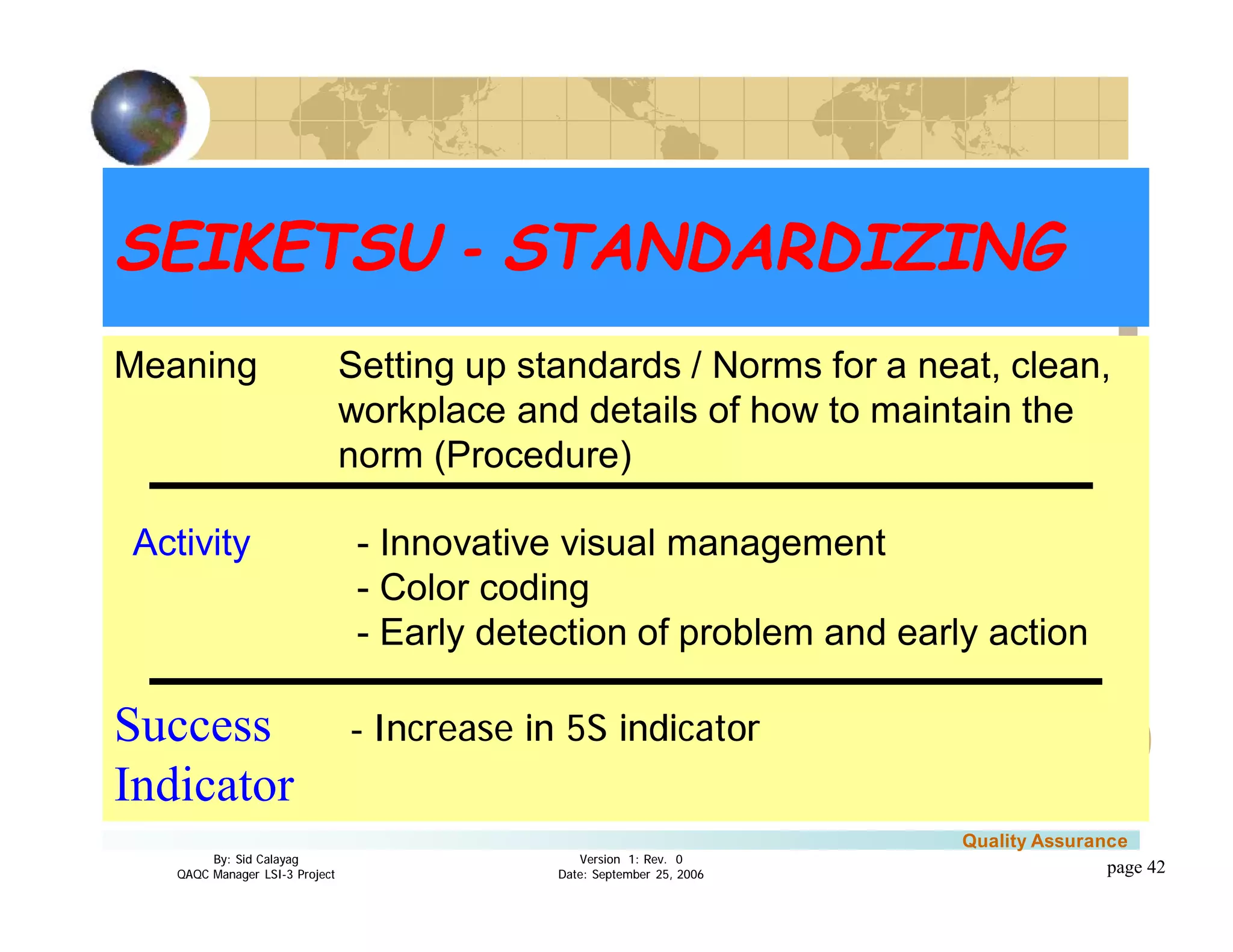

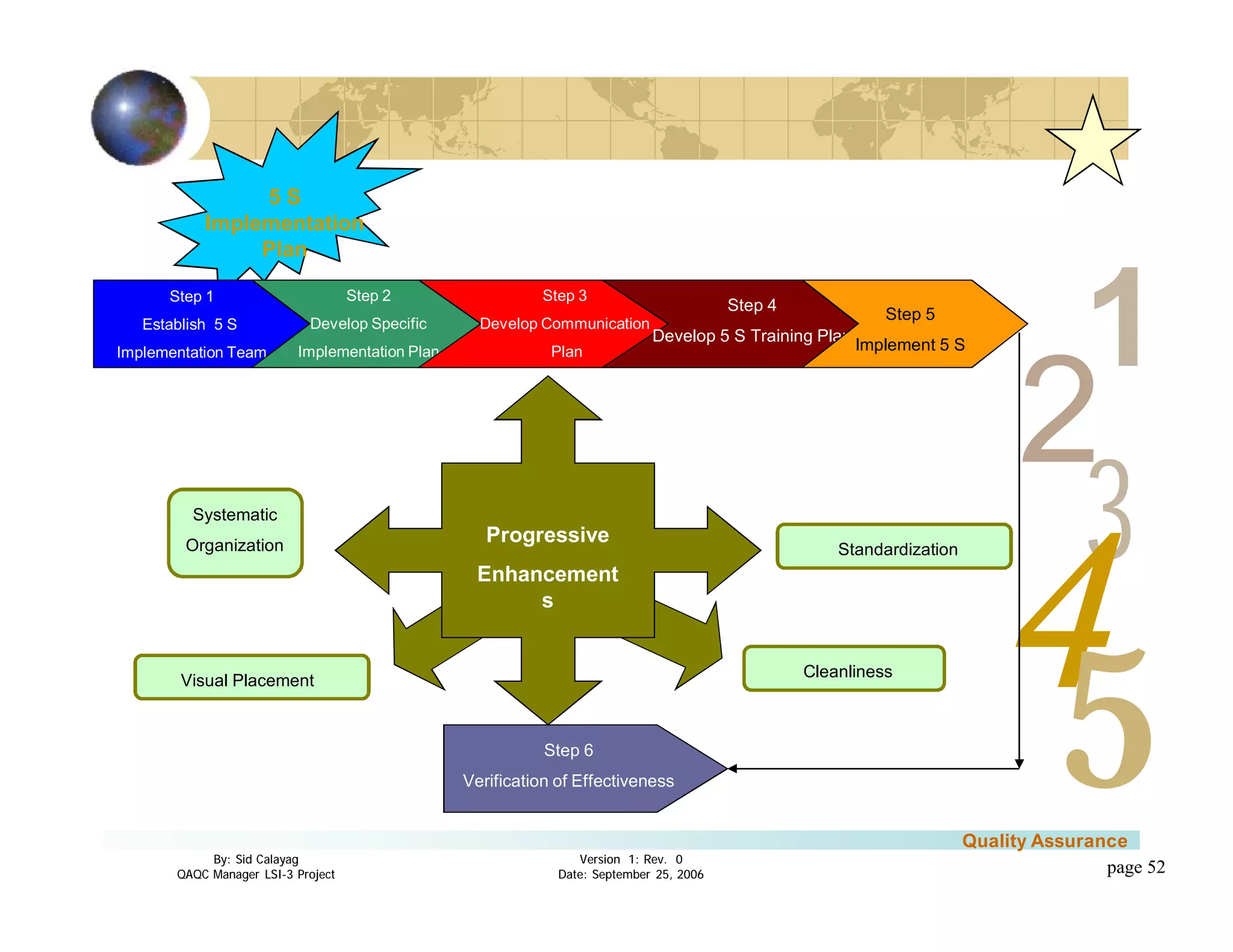

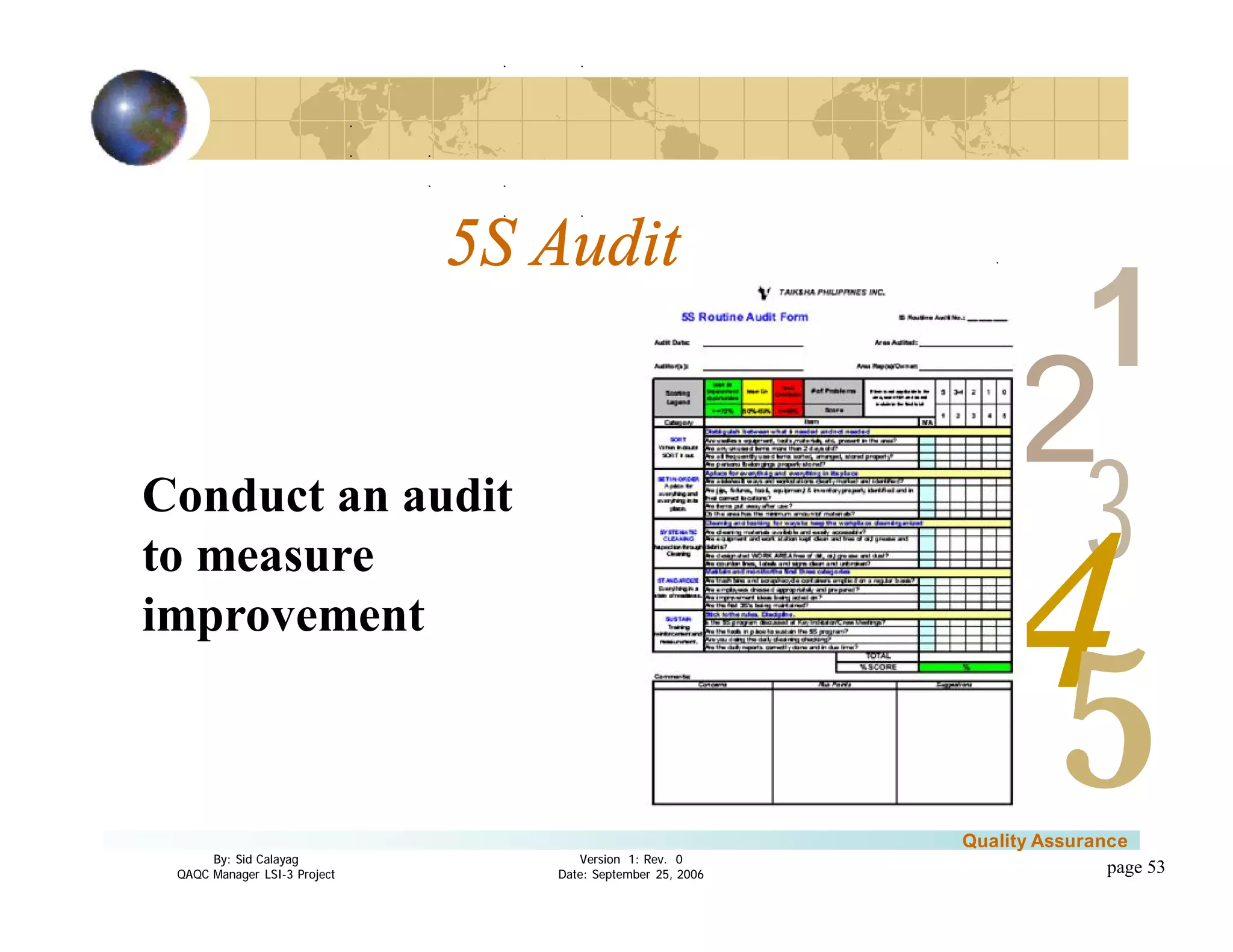

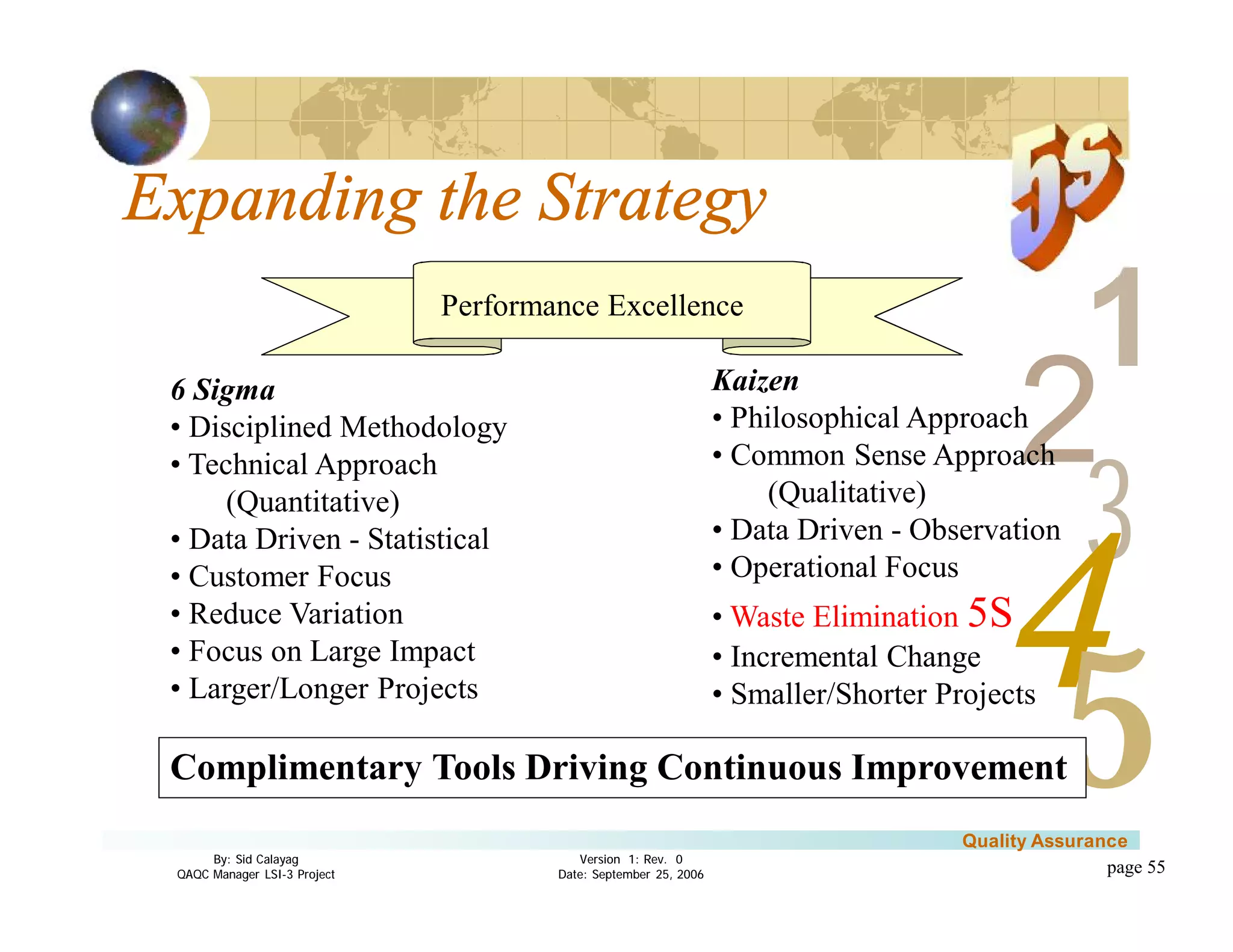

The document outlines a quality assurance program focused on implementing the 5S methodology (Sort, Set in order, Shine, Standardize, Sustain) to improve project performance and efficiency. It emphasizes the need for housekeeping, effective organization, and waste elimination to enhance productivity and reduce costs. The program aims to create a structured work environment through defined practices and visual management techniques.