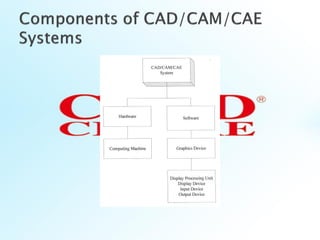

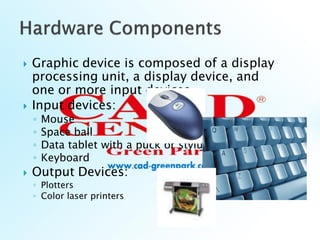

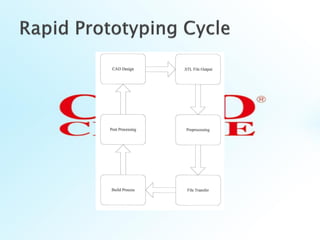

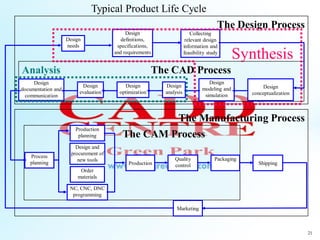

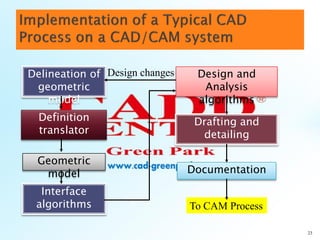

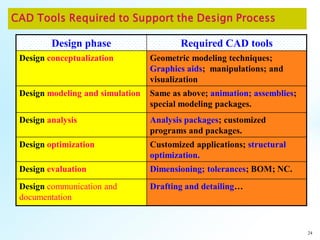

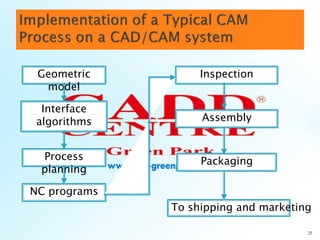

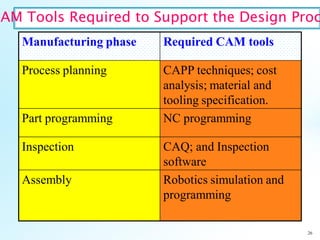

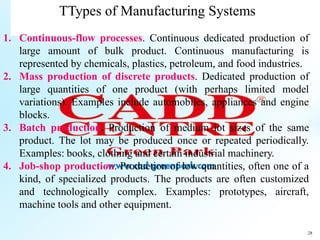

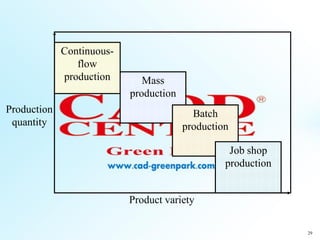

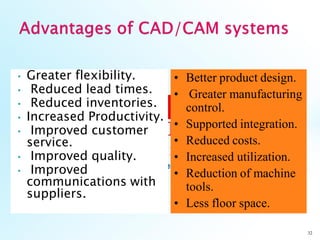

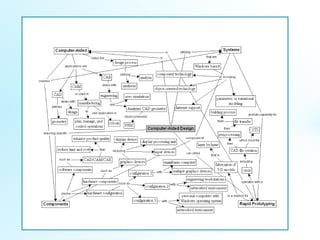

The document outlines the integration of computer systems in design and manufacturing processes, highlighting the roles of CAD (computer-aided design), CAM (computer-aided manufacturing), and CAE (computer-aided engineering). It details workflows, hardware and software requirements, rapid prototyping methods, and different manufacturing types such as continuous-flow and job-shop production. The emphasis is on the benefits of automation and technology in improving efficiency, product quality, and communication in manufacturing operations.