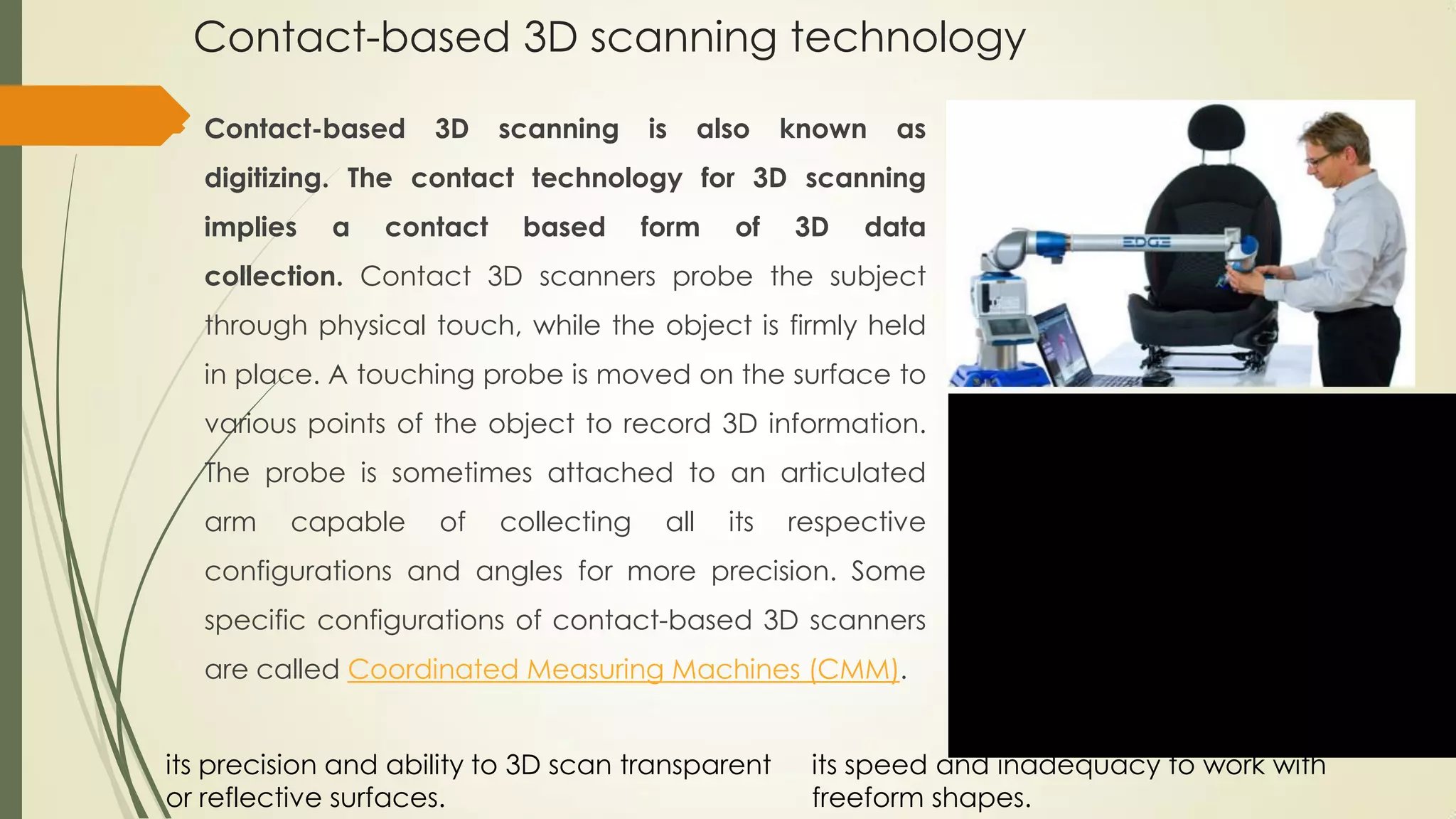

3D scanning technology allows capturing the shape of physical objects and environments and converting them into digital 3D models. There are several 3D scanning technologies that differ in their principles such as laser triangulation, structured light, photogrammetry, and contact-based scanning. These technologies find applications in industries like automotive, aeronautics, dental, jewelry, video games, and movies. Each technology has advantages and limitations related to aspects like speed, resolution, ability to scan certain surfaces, and sensitivity to lighting conditions.