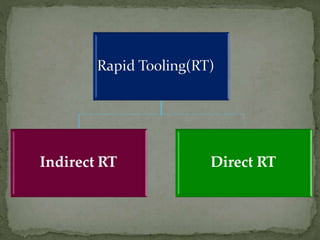

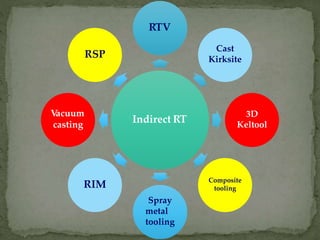

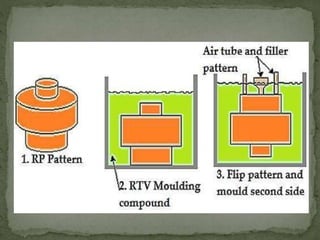

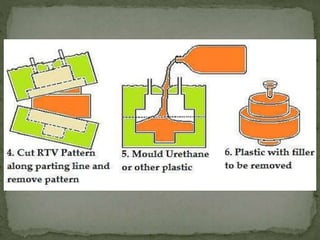

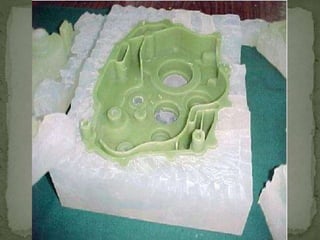

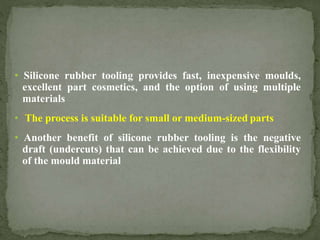

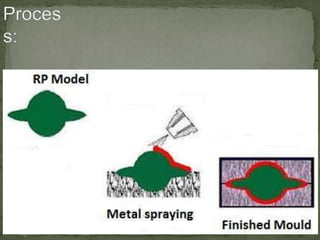

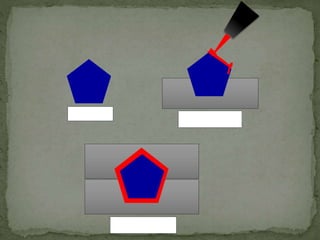

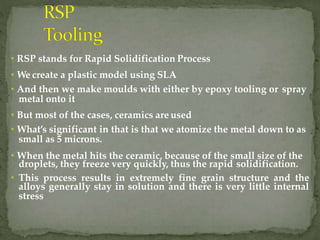

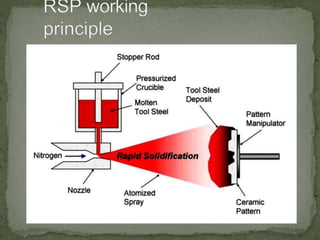

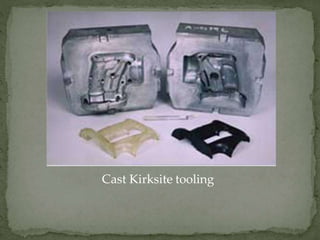

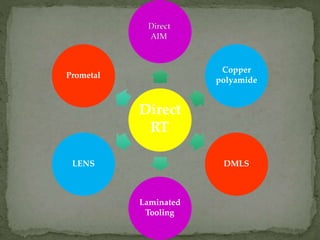

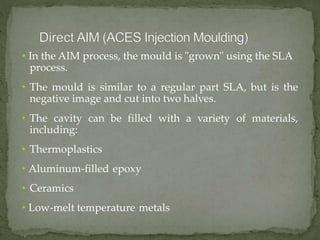

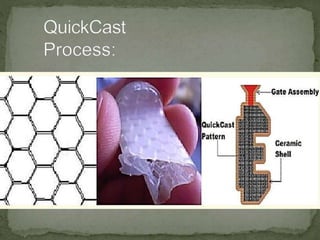

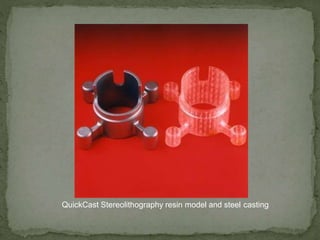

Rapid tooling uses rapid prototyping processes to quickly fabricate molds and tools for low to medium volume production of prototype parts. It can be classified as either indirect tooling, which uses an RP pattern to create a mold, or direct tooling, which builds the actual mold directly from a 3D CAD model. Indirect methods like silicone rubber tooling and spray metal tooling allow fabrication of molds in a fraction of the time and cost of conventional tooling but have shorter tool life. Direct methods like AIM and QuickCast SLA can produce metal parts in less time than traditional investment casting.