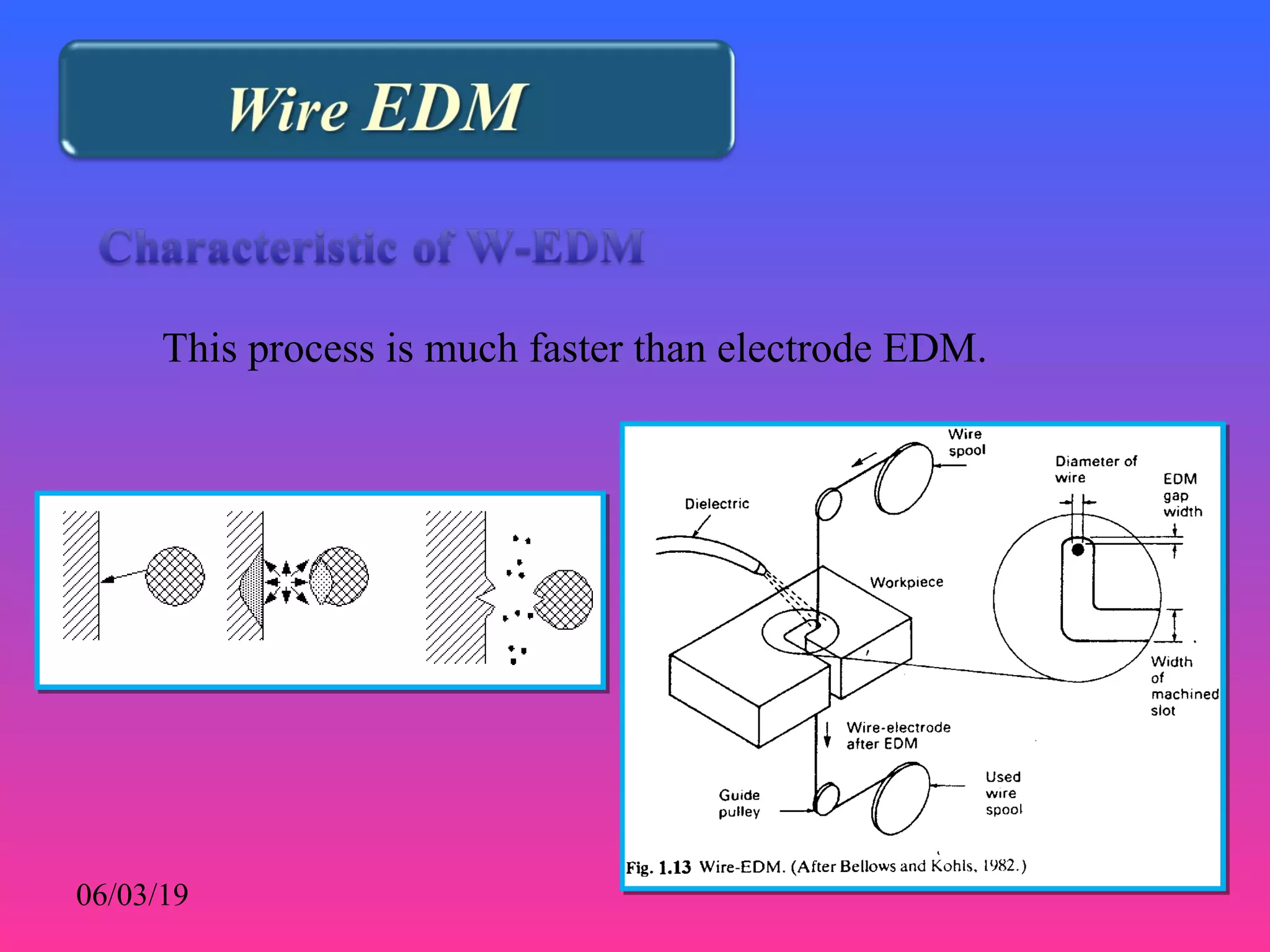

The document describes the process of Electrical Discharge Machining (EDM), where a tool acts as a cathode and is immersed in dielectric fluid, allowing for the erosion of a workpiece through spark discharges created by applied DC voltage. Key aspects include material removal rates, electrode wear ratios, and the importance of dielectric fluid to control electrical resistance and help with debris removal. Various parameters such as electrode material, shape, and gap distance are crucial for achieving desired machining outcomes.