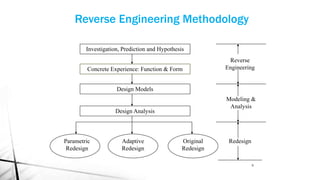

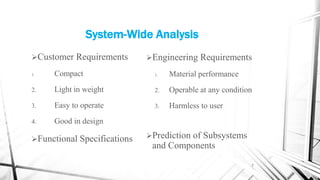

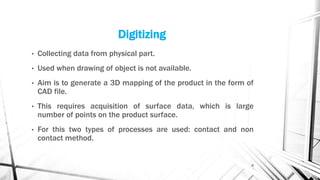

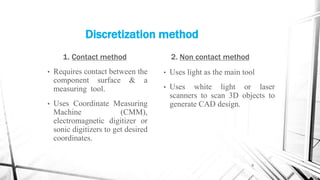

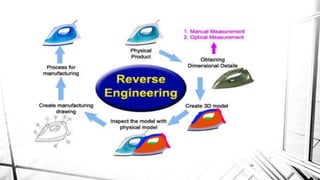

Reverse engineering is a systematic process of analyzing existing systems or products to understand their design, functionality, and potential for improvement. The process involves digitizing physical parts to create 3D CAD models, which can then be manipulated and analyzed. This allows existing products to be redesigned to add new functionality, improve quality, or extend useful life. Reverse engineering is commonly used when original documentation is lacking, products need repair, or new designs can be created more efficiently than starting from scratch. It has applications in manufacturing, software, and medical fields.

![References

[1] Durupt A., Remy S. and Ducellier G (2010), Knowledge Based Reverse

Engineering- An Approach for Reverse Engineering of a Mechanical Part, ASME

Journal of Computing and Information Science in Engineering, 10, pp.044501-1.

[2] Lefever D. D. and Wood K. L. (1996), Design for Assembly Technique in Reverse

Engineering and Redesign, ASME Design Theory and Methodology Conference, pp.

78712-1063.

[3] Shooter Steven (2008), Reverse Engineering to Design Forward, American Society

for Engineering Education, pp.2008- 1170.

17](https://image.slidesharecdn.com/reverseengineeringbydsp-160921112956/85/Reverse-engineering-17-320.jpg)