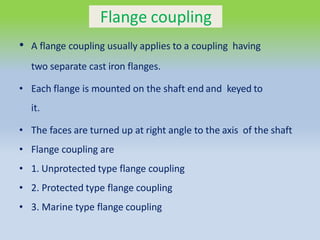

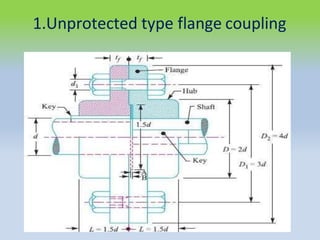

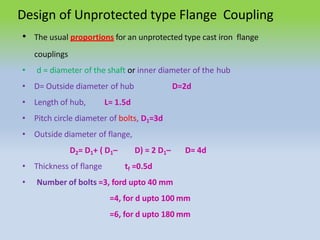

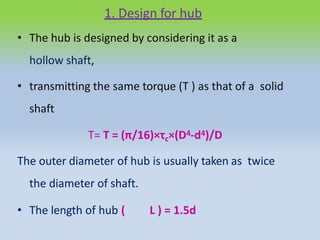

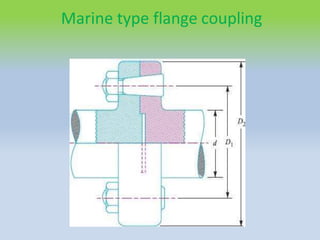

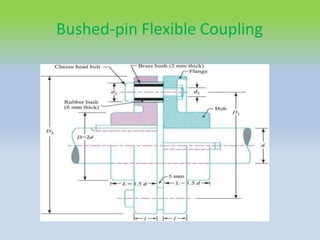

This document describes different types of flange couplings, including their design and components. It discusses unprotected, protected, and marine type flange couplings. It also covers the design of a bushed-pin flexible coupling, which is a modification of the rigid flange coupling that uses rubber or leather bushes over the coupling pins to allow some flexibility. Key aspects covered include hub, key, flange, bolt, and pin/bush designs and specifications.

![• Direct shear stress due to pure torsion in the

coupling halve

• τ=W/[ (π/4) (d 1 )]

2

• maximum bending moment on the pin

• M =W (l/2 +5mm)

• bending stress

σ= M / Z

= W (l/2 +5mm)/ (π/32) (d 1

3)](https://image.slidesharecdn.com/11ccouplings-flangecoupling-210302065547/85/11-c-couplings-flange-coupling-23-320.jpg)

![• Maximum principal stress

= 1/2[σ +(σ+4τ2 )1/2]

• maximum shear stress on the pin

= 1/2(σ+4τ2 )1/2

• The value of maximum principal stress varies

from 28 to 42 MPa](https://image.slidesharecdn.com/11ccouplings-flangecoupling-210302065547/85/11-c-couplings-flange-coupling-24-320.jpg)