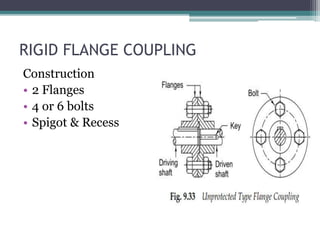

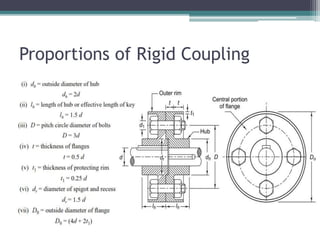

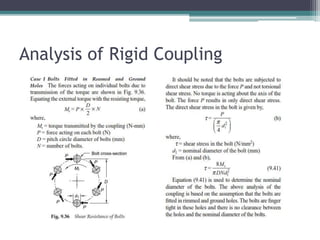

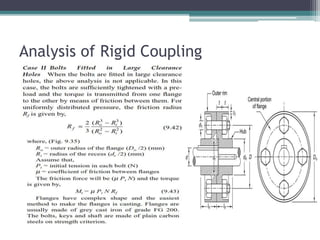

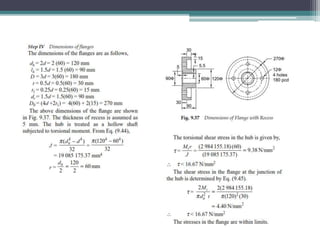

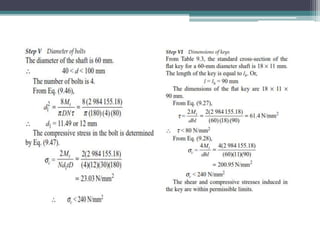

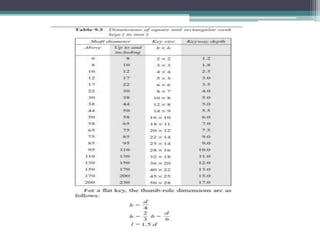

The document discusses rigid flange couplings used in mechanical engineering, highlighting their construction, advantages, and disadvantages. It presents problems related to the design and analysis of rigid couplings for specific power transmission scenarios, including calculations for bolt diameters and material selection. References for further reading are provided to support the design processes involved.