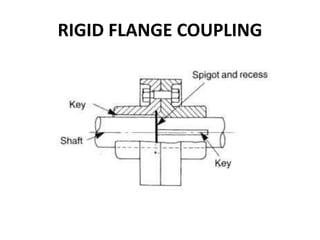

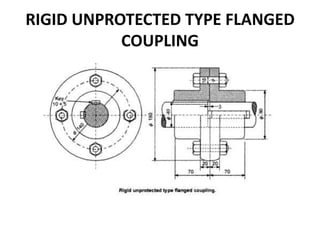

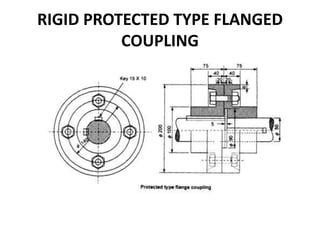

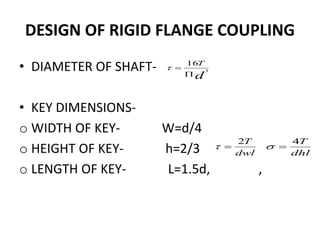

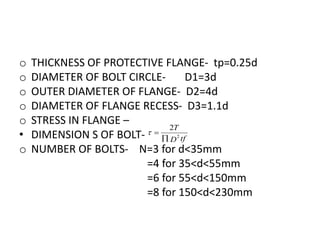

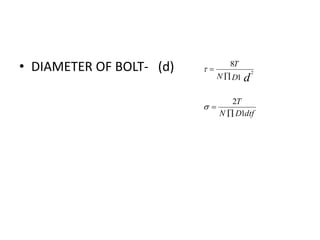

This document describes the design of a rigid flange coupling. It consists of two flanges, one keyed to the driver shaft and the other to the driven shaft. Bolts and keys are used to couple the flanges together and maintain alignment between the two shafts. Dimensions and formulas are provided for the key, hub, flange, bolts, and stresses in each component based on the shaft diameter. Rigid flange couplings are used to connect shafts, allow for some misalignment, reduce shock transmission, and introduce overload protection while transferring power from one shaft to another.