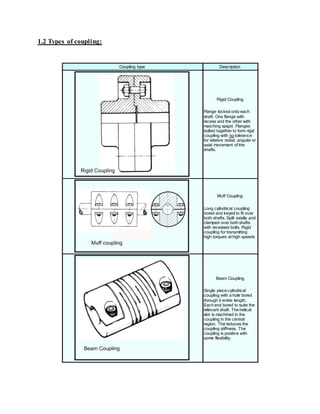

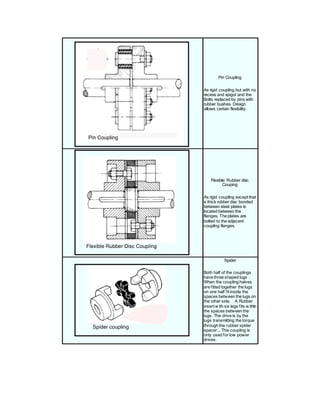

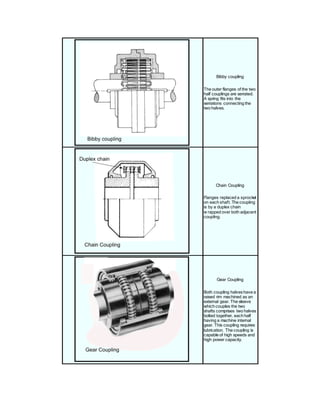

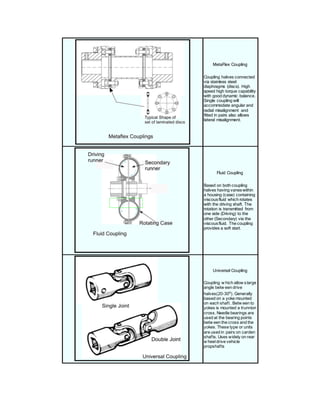

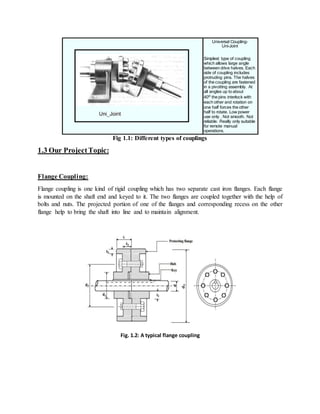

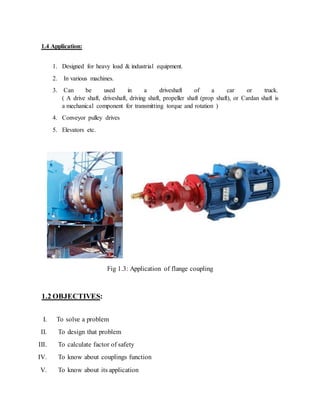

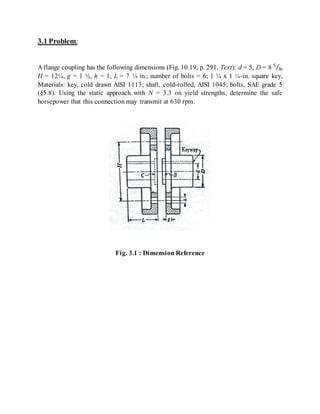

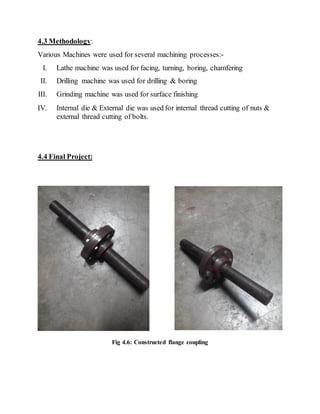

This report details the design and construction of a flanged coupling as part of an engineering course at Khulna University of Engineering & Technology. The project involved creating a flanged coupling using local materials, analyzing various stresses, and calculating safety factors, concluding that the coupling can handle small misalignments without failure. Insights on coupling types, historical background, and theoretical principles are also provided.

![References:

[1] FAIRES VIRGIL MORING, “DESIGN OF MACHINE ELEMENTS”, 4th edition, The

Macmillan Company, New York/Collier-Macmillan Limited, London

[2] Jain R.K., “ Production Technology”, 16th edition, 2-B, Nath Market, Nai Sarak, Delhi-

110006

[3] Mechanical Design Data Manual Chapter 15

[4] https://www.google.com.bd/webhp?sourceid=chrome-instant&ion=1&espv=2&ie=UTF-

8#q=historical+background+of+flange+coupling

[5] http://www.wisegeek.com/what-is-a-flange-coupling.htm

[6] http://www.roymech.co.uk/Useful_Tables/Drive/Drive_Couplings.html](https://image.slidesharecdn.com/final-150820101053-lva1-app6892/85/Report-on-Flange-Cupling-35-320.jpg)