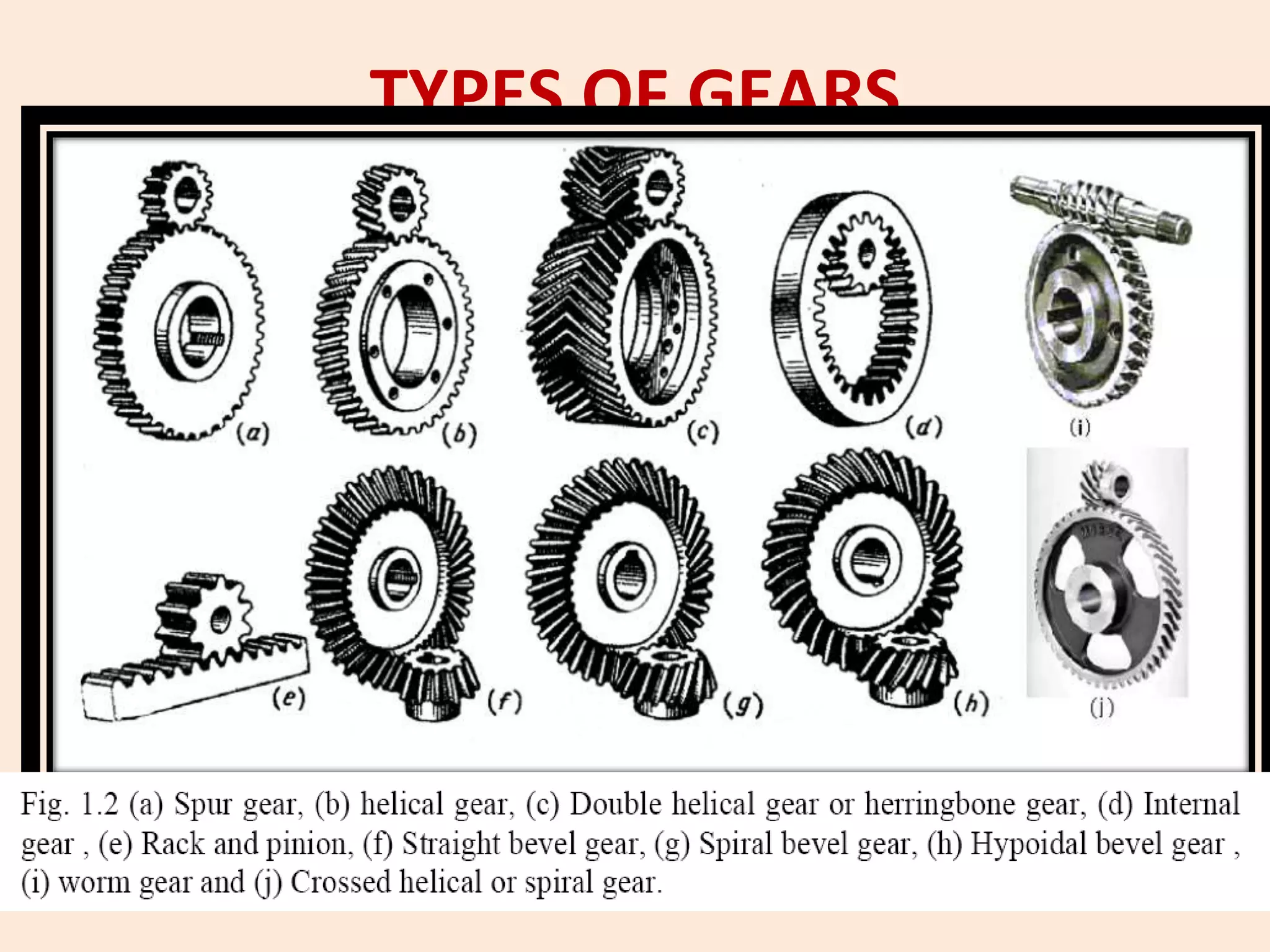

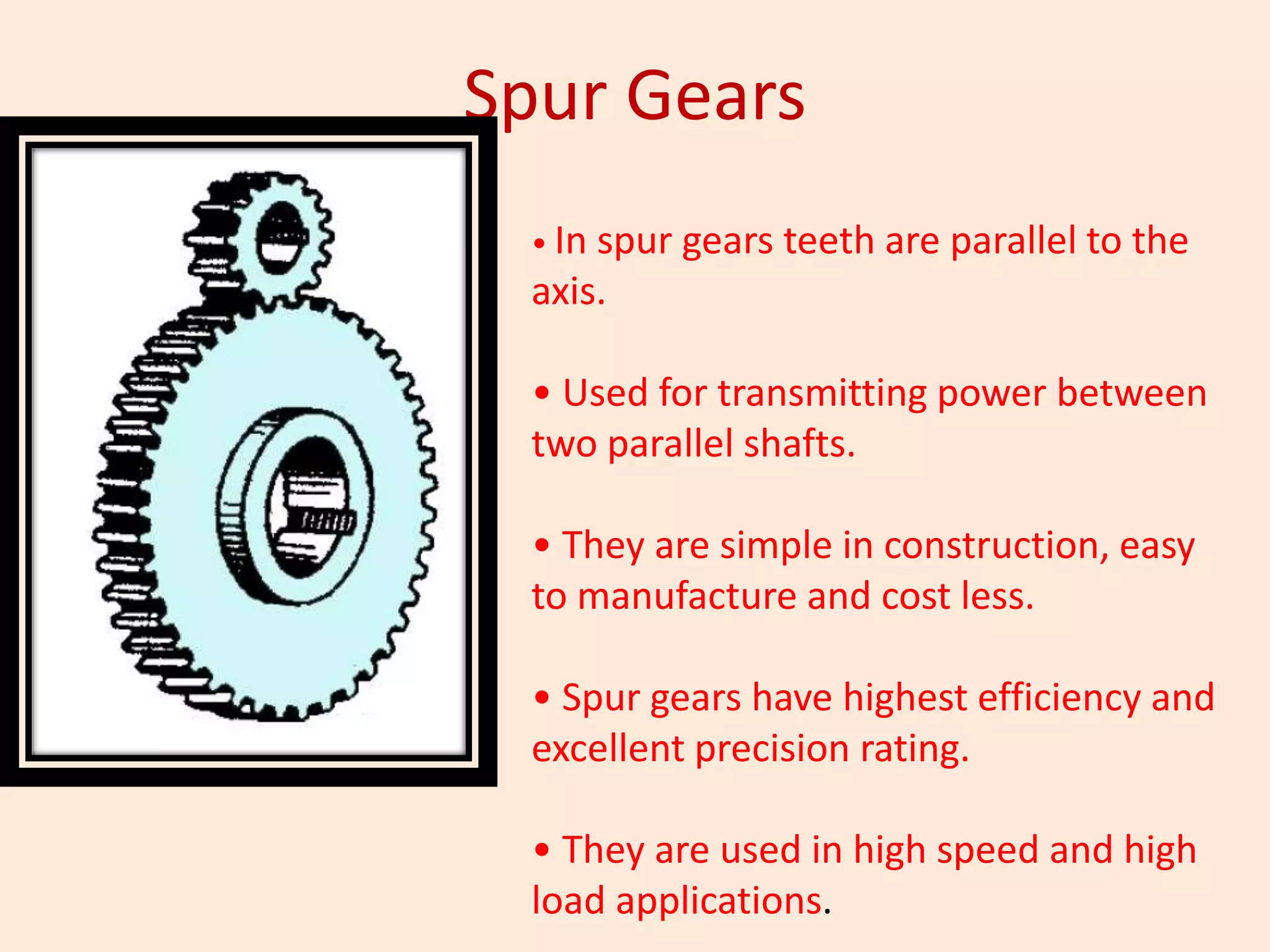

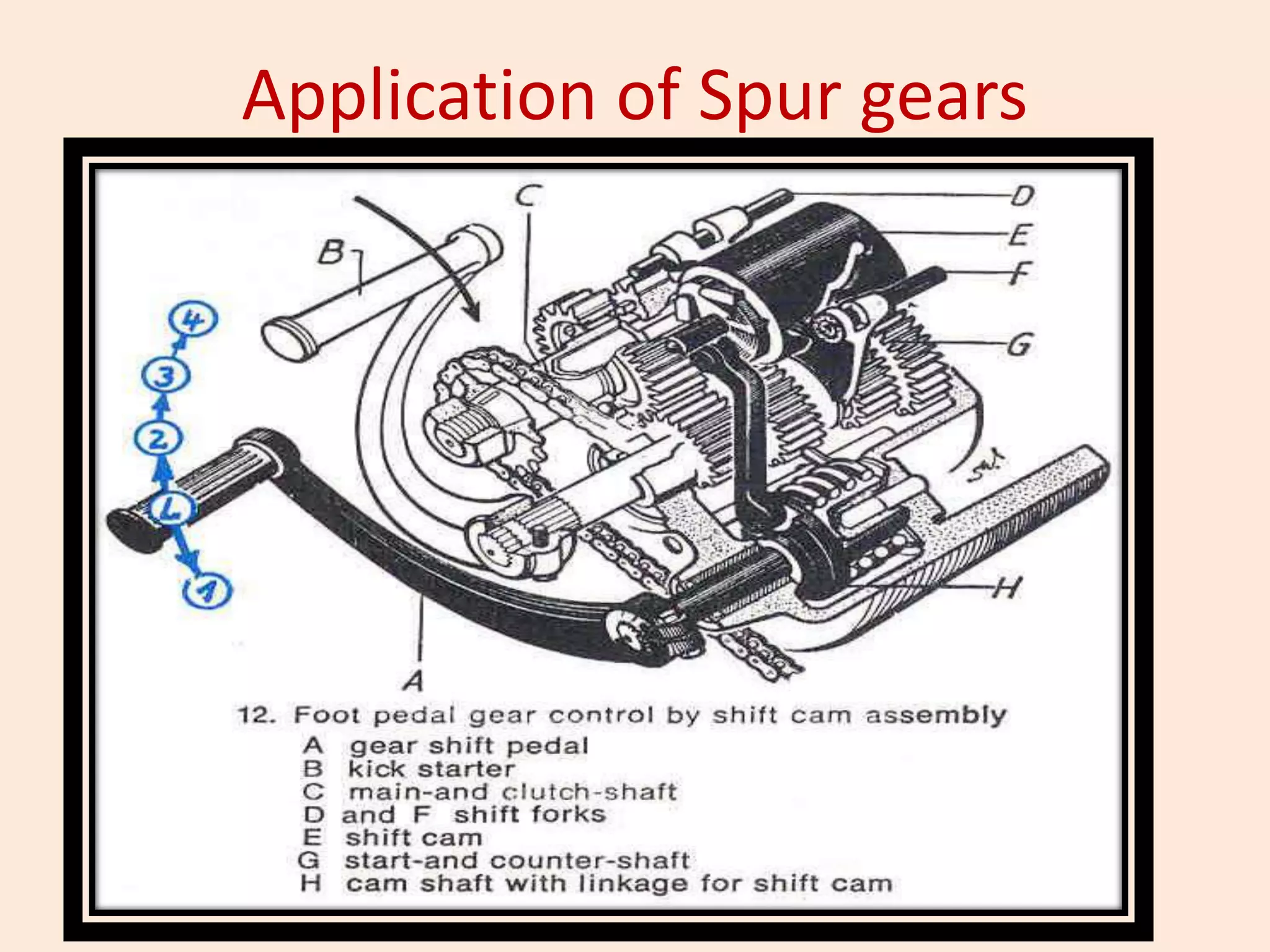

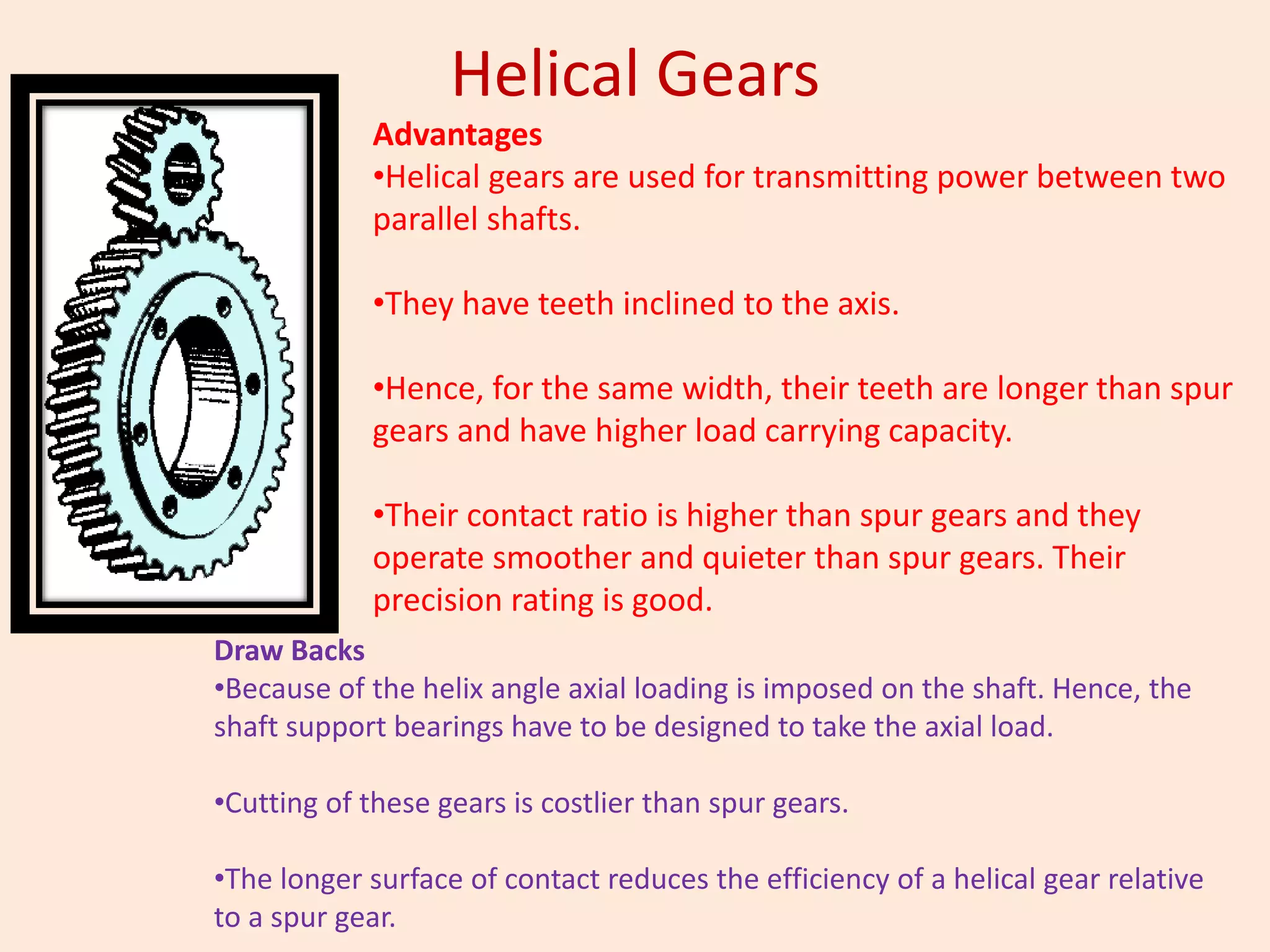

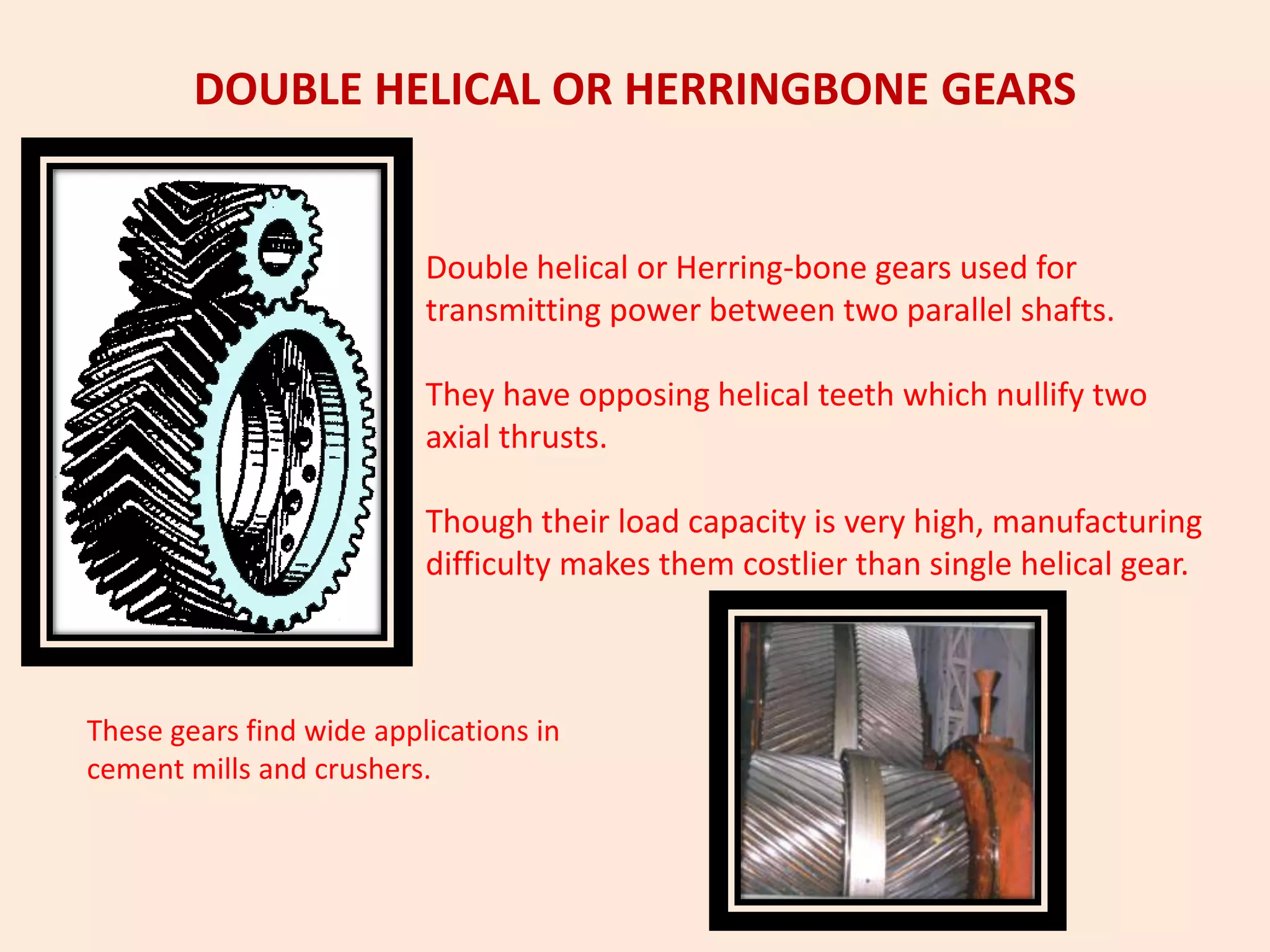

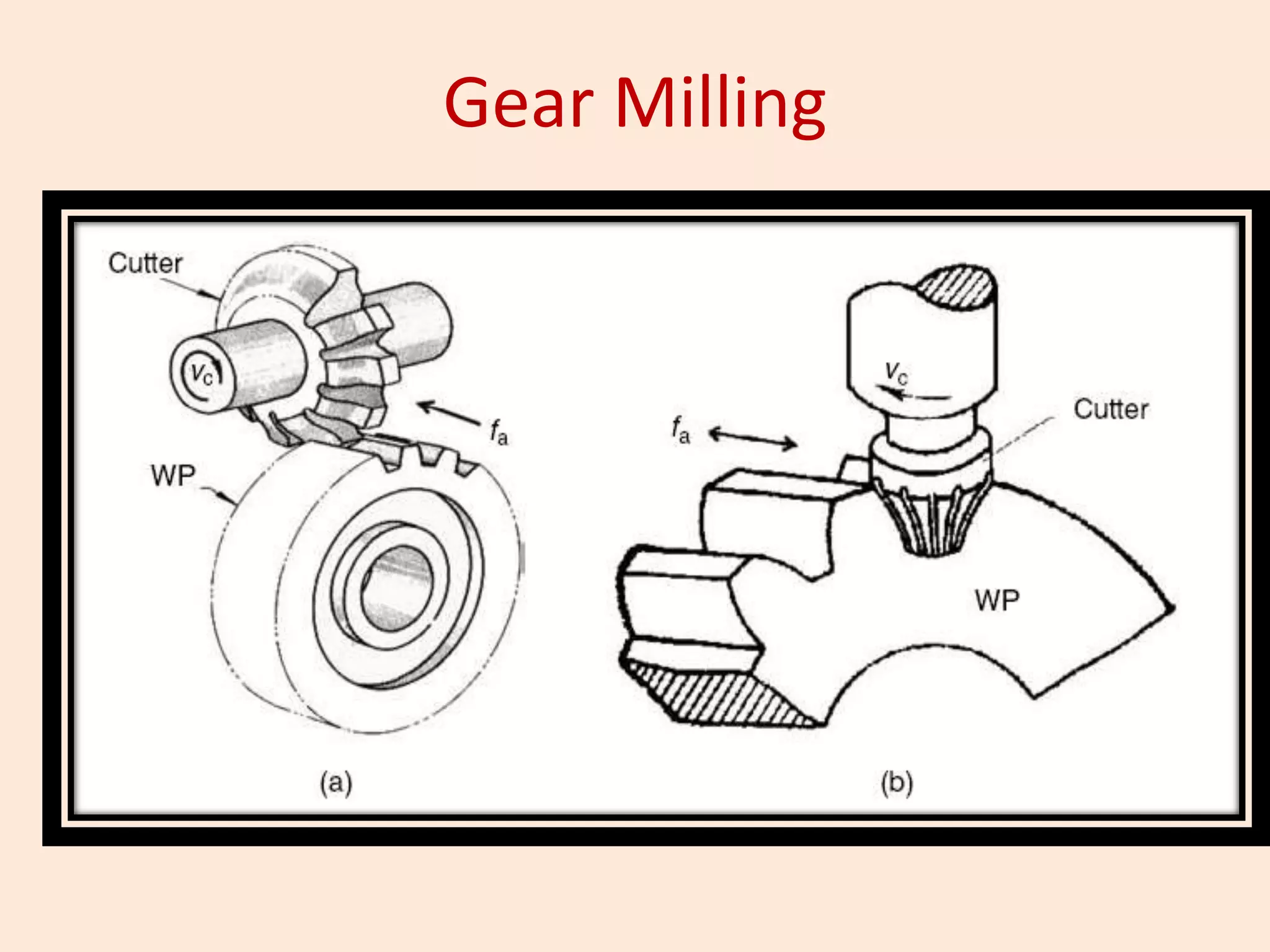

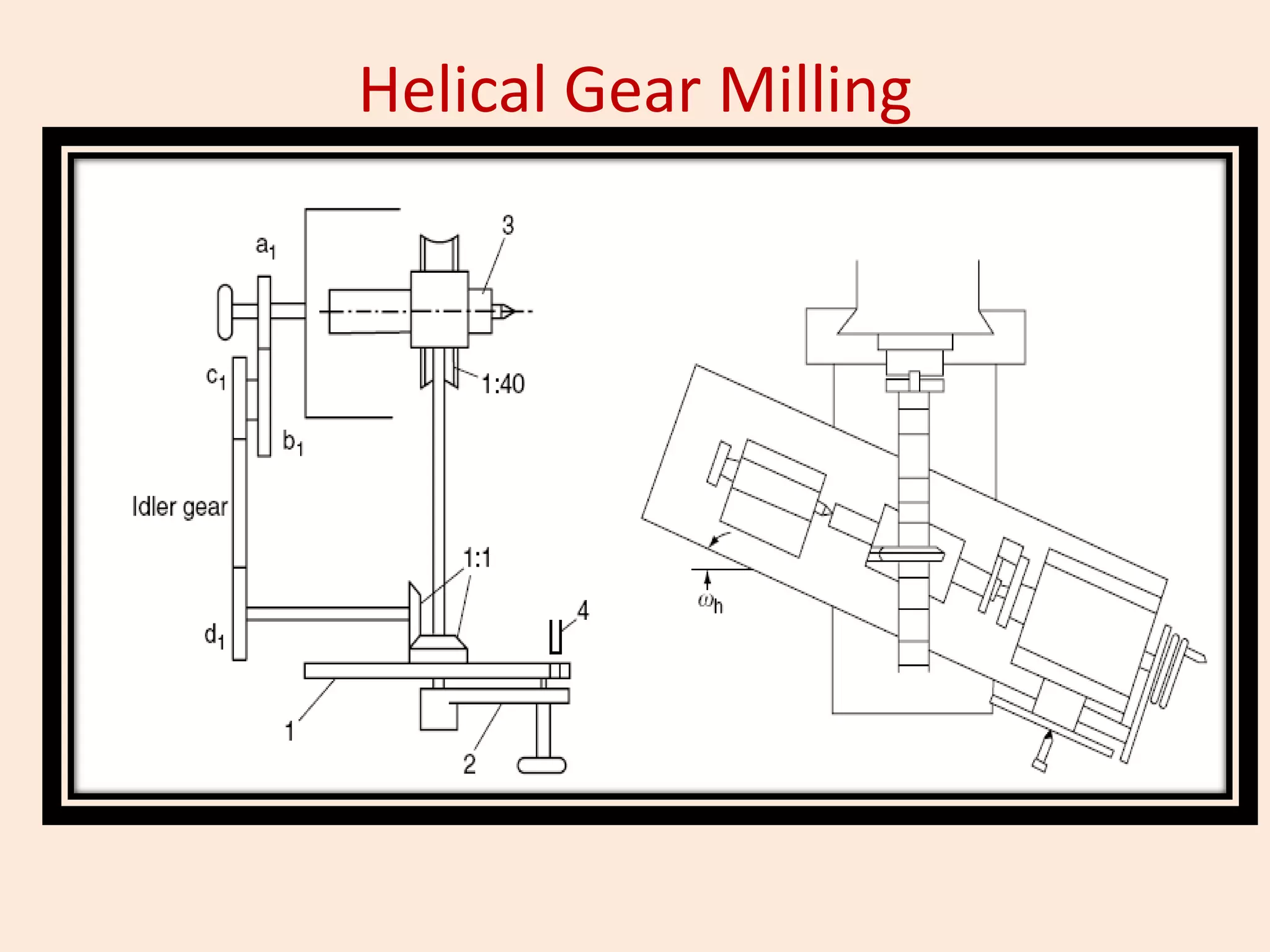

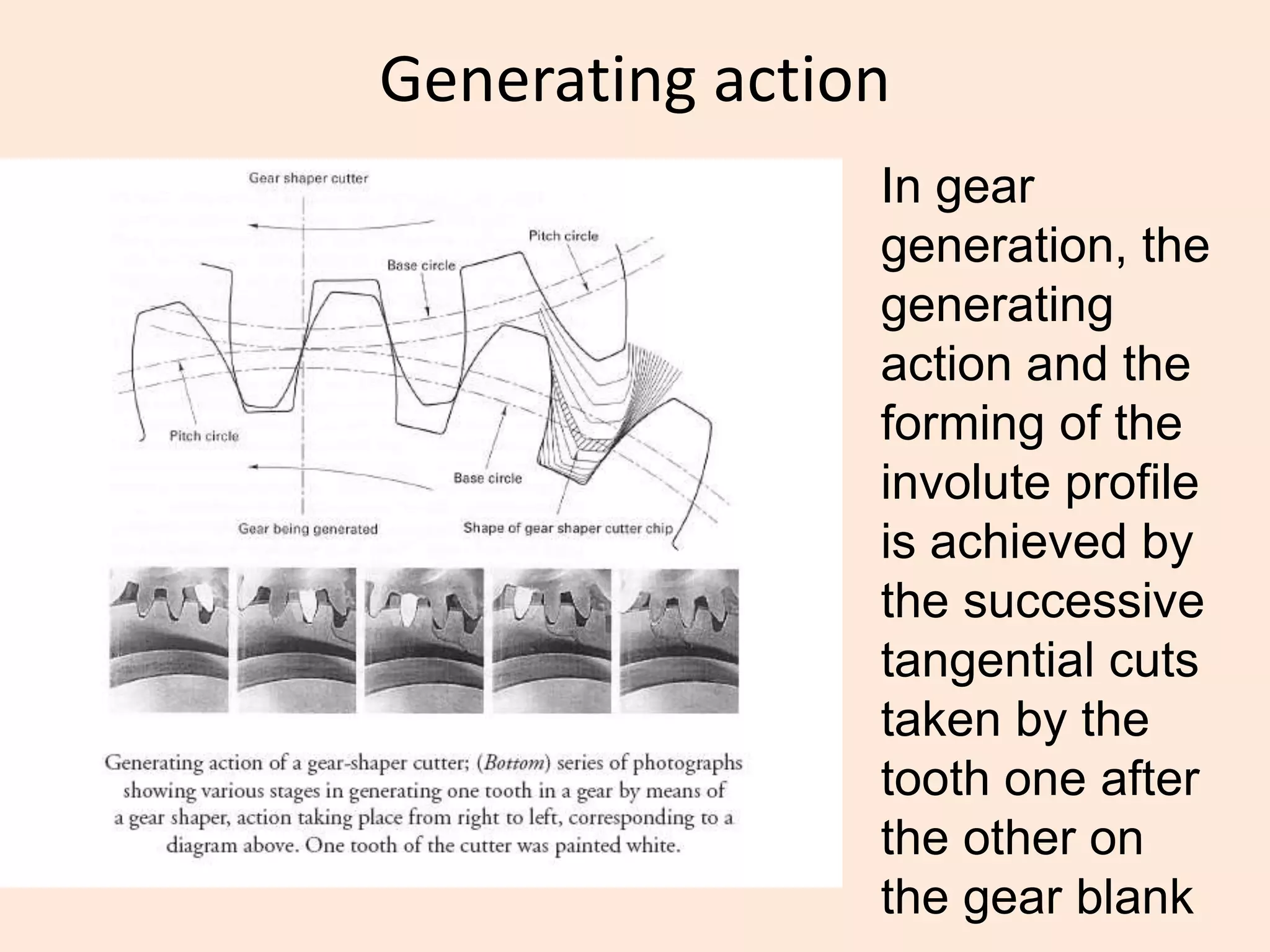

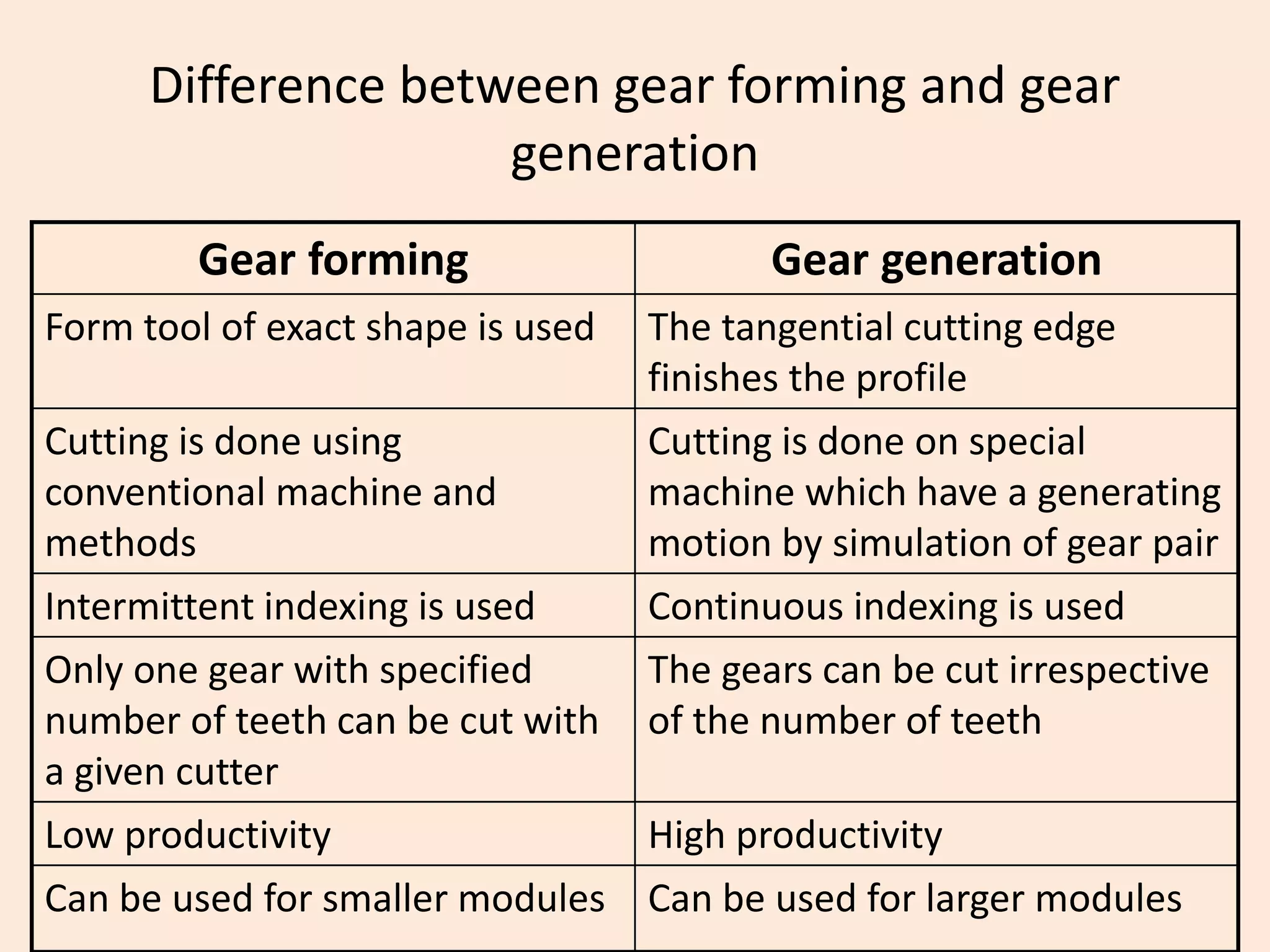

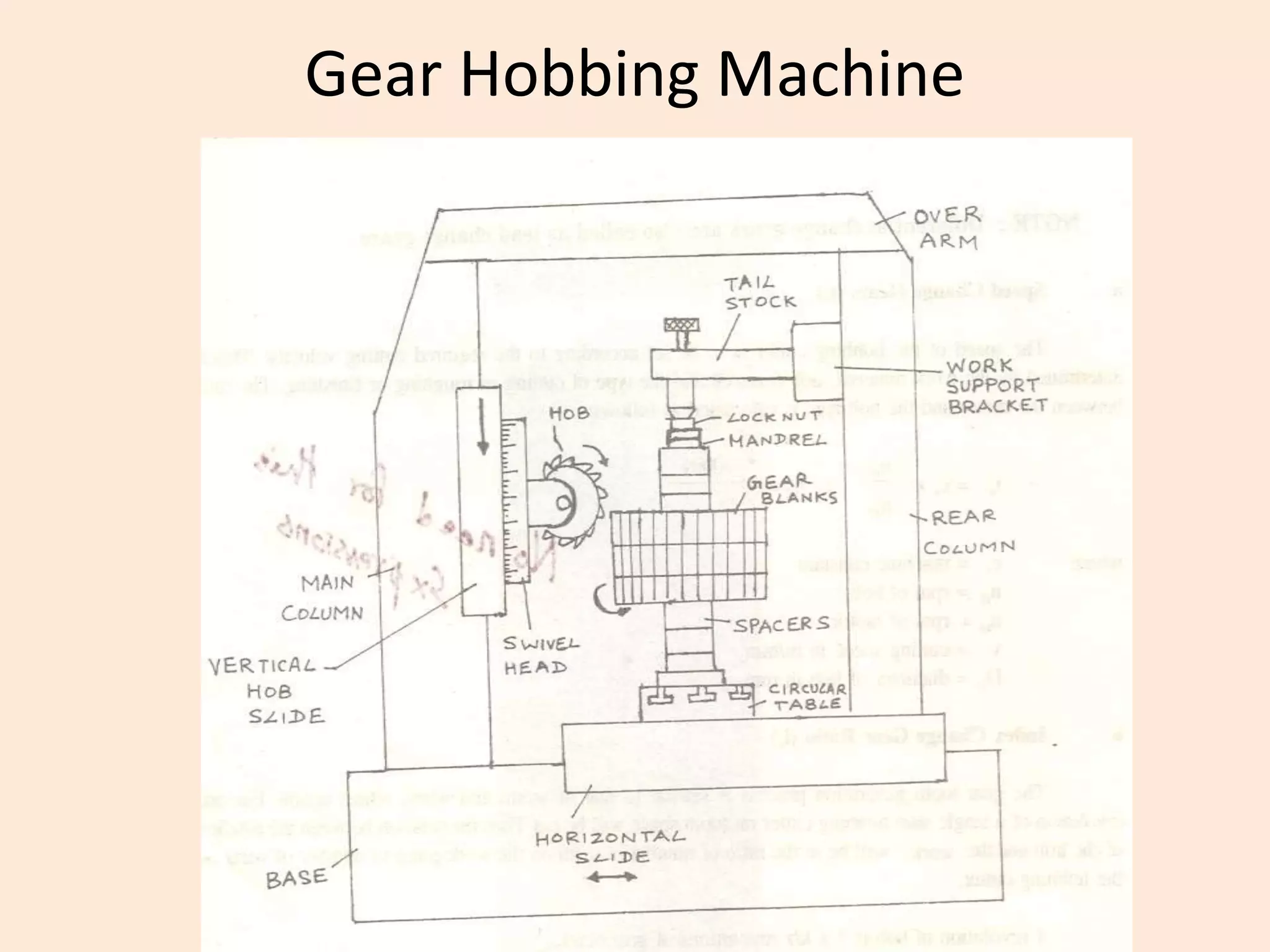

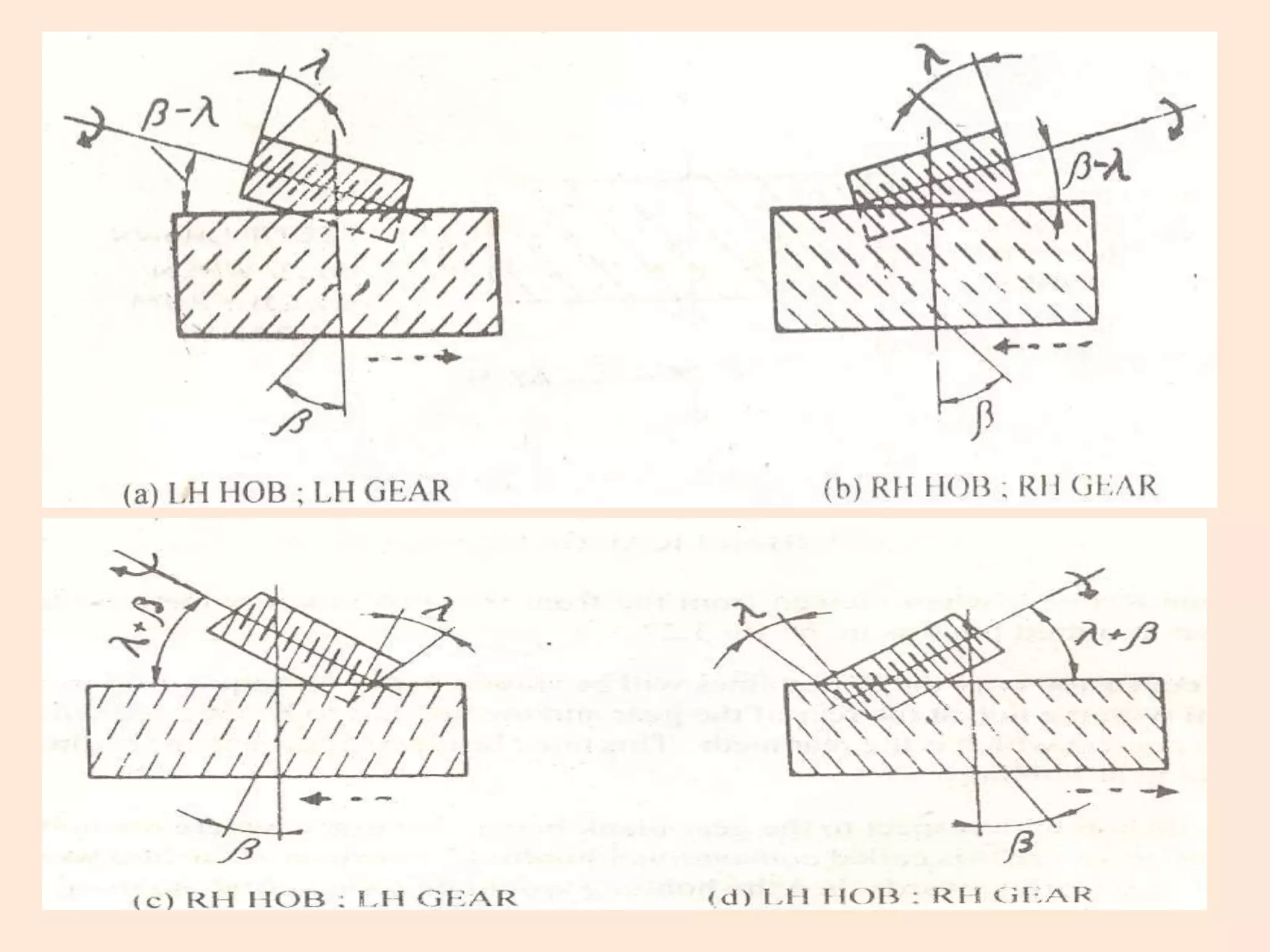

This document discusses different types of gears and gear manufacturing methods. It describes various gear types including spur gears, helical gears, bevel gears, and worm gears. It then covers different gear manufacturing classification and processes, including gear forming methods like milling and broaching, and gear generation methods like hobbing and gear shaping. Hobbing and gear shaping are described as the main gear generation techniques that can generate gears continuously and with high productivity. The advantages and limitations of different gear manufacturing methods like hobbing and gear shaping are also summarized.