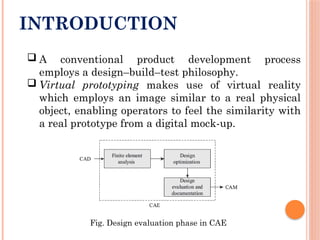

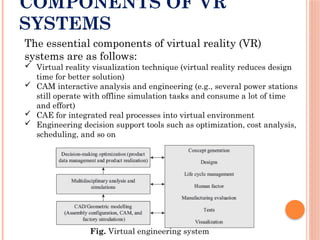

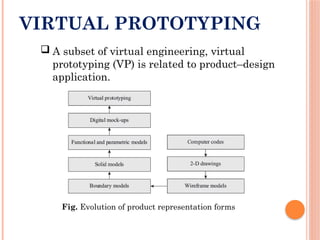

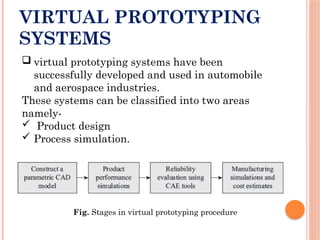

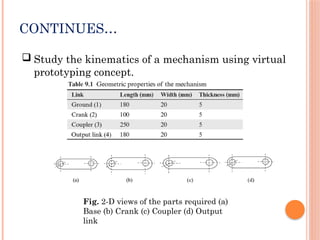

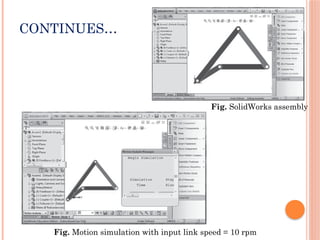

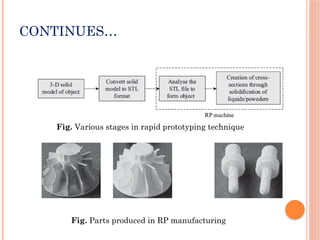

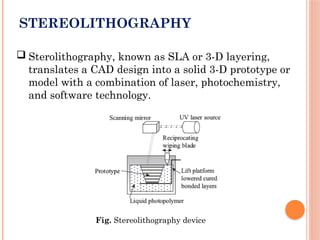

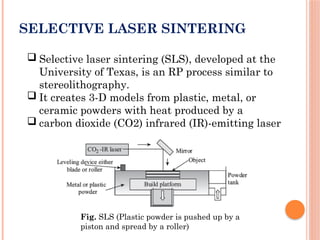

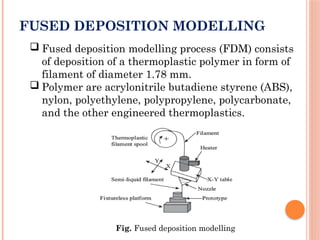

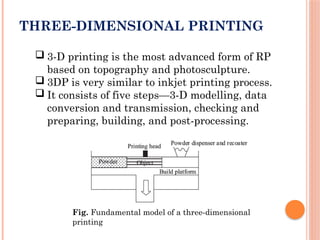

The document discusses basic design evaluation tools, focusing on virtual engineering, virtual prototyping, and rapid prototyping techniques. Virtual engineering aids in decision-making and control through simulation, while virtual prototyping applies to product design in various industries. Rapid prototyping accelerates the product development process by generating physical prototypes quickly, with methods including stereolithography, selective laser sintering, fused deposition modeling, and 3D printing.