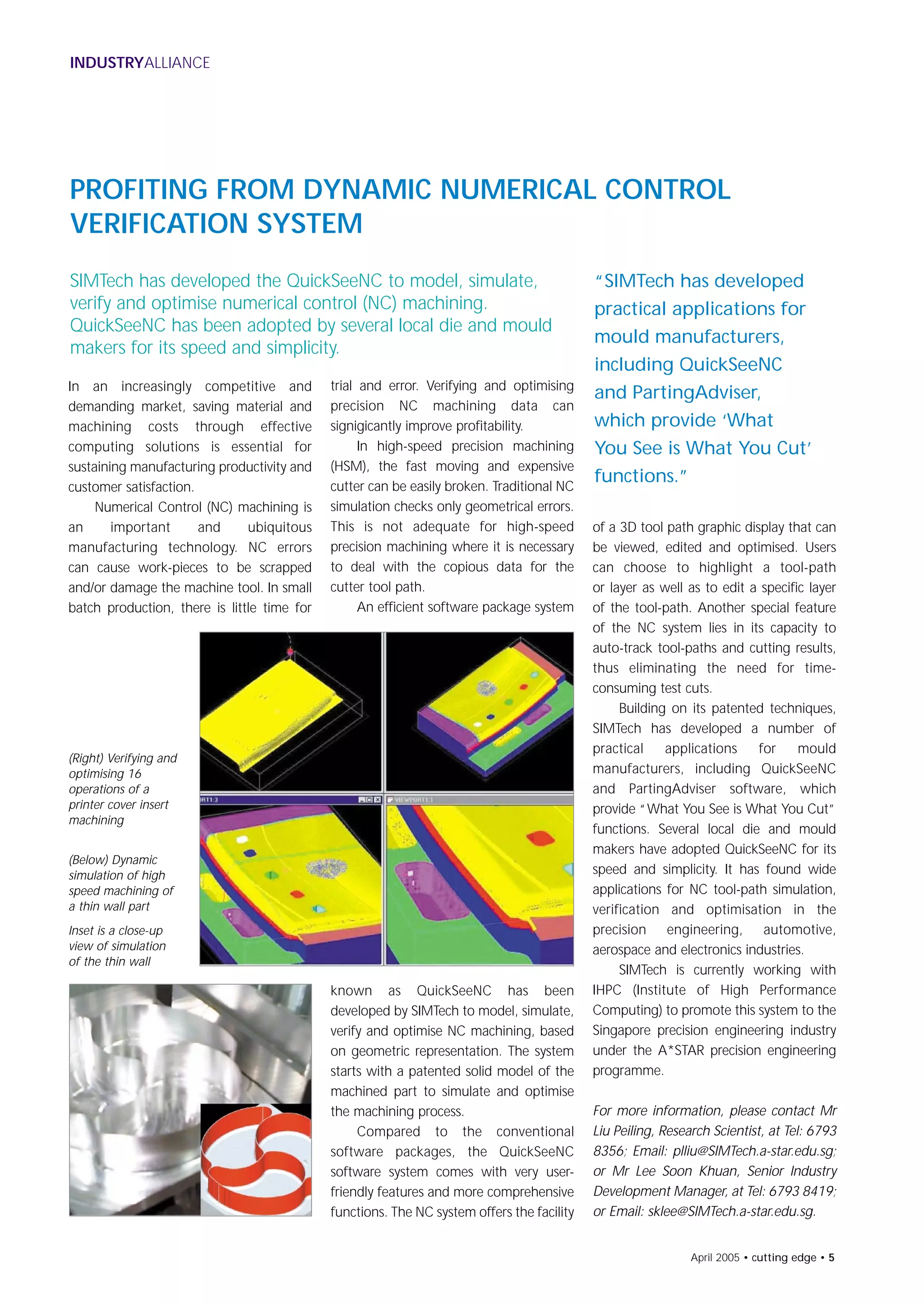

SIMTech developed QuickSeeNC, a numerical control (NC) machining verification system that models, simulates, verifies and optimizes NC tool paths. QuickSeeNC has been adopted by several local die and mould makers because it is fast and simple to use. It provides "What You See is What You Cut" functions to efficiently model, simulate, verify and optimize complex NC machining processes.