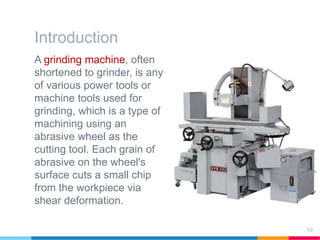

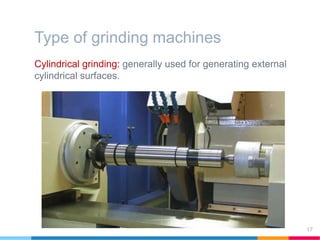

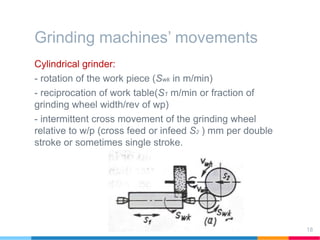

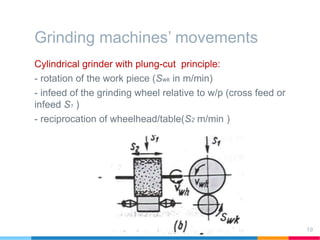

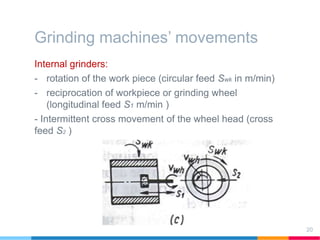

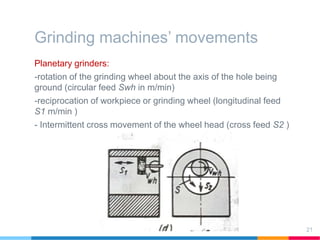

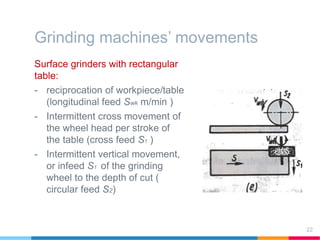

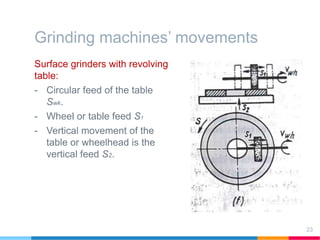

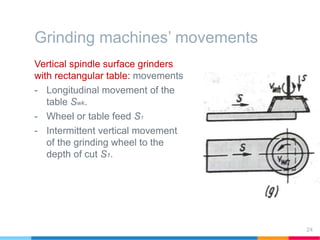

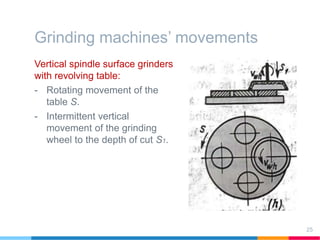

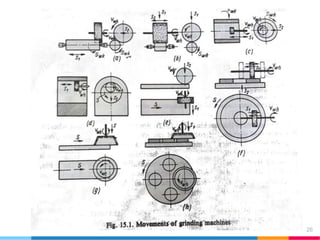

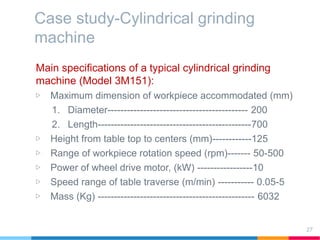

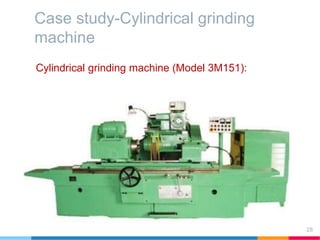

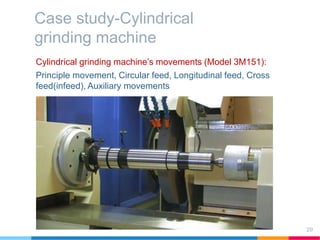

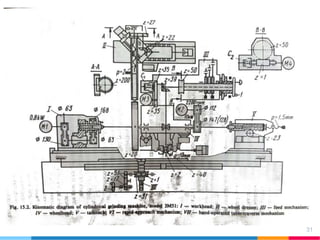

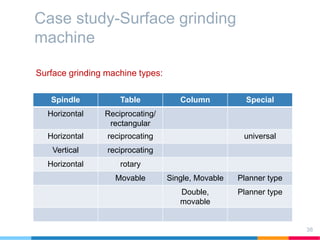

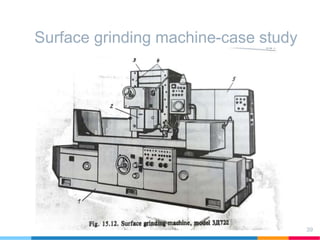

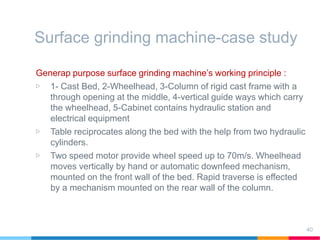

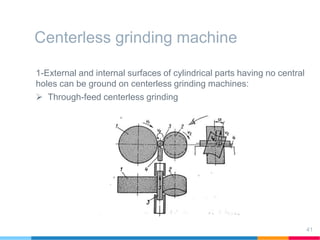

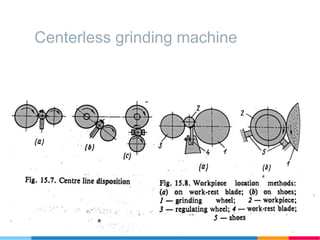

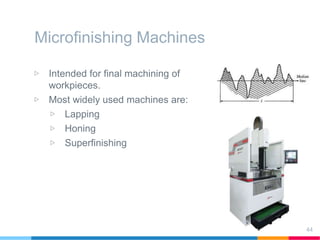

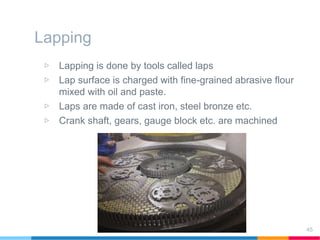

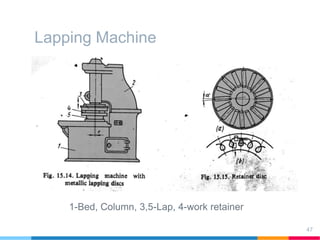

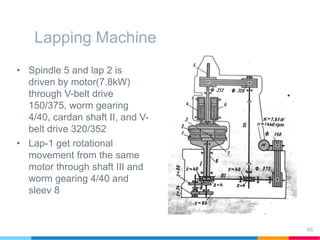

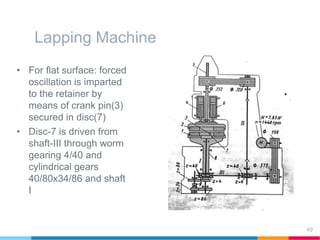

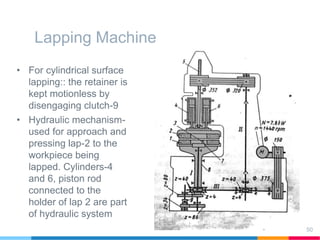

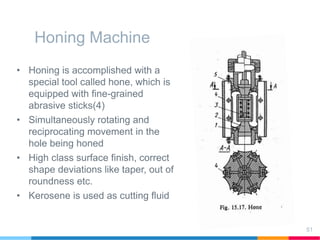

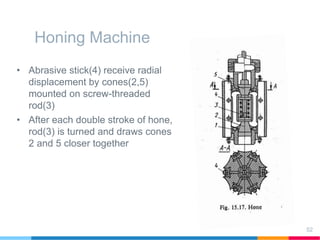

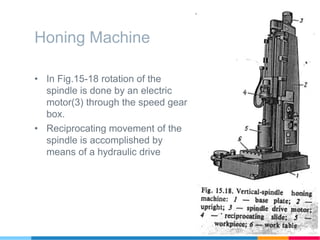

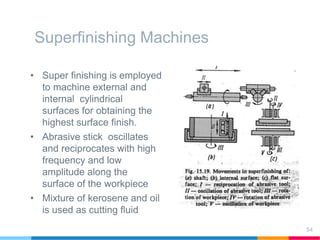

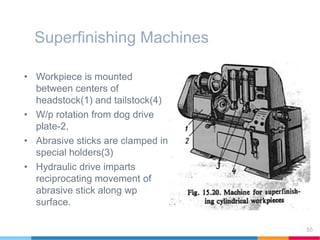

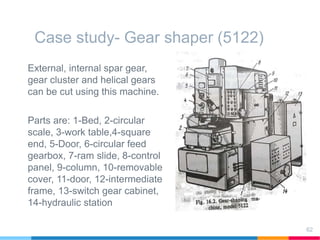

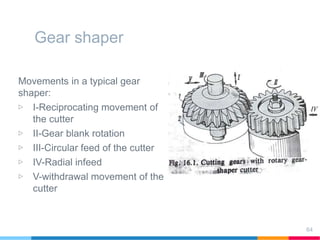

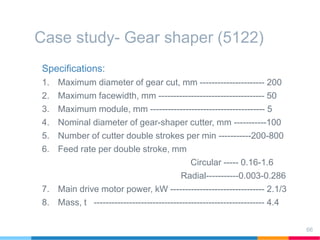

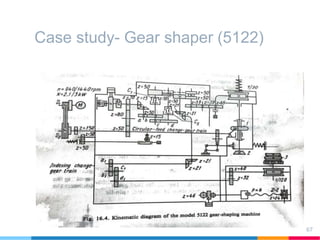

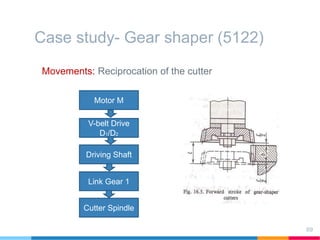

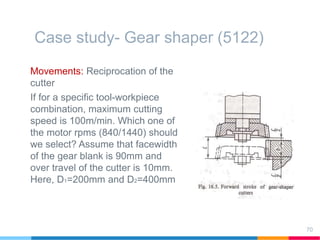

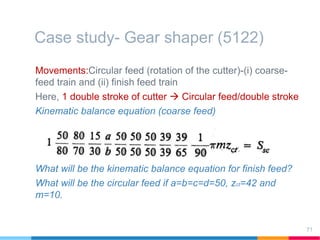

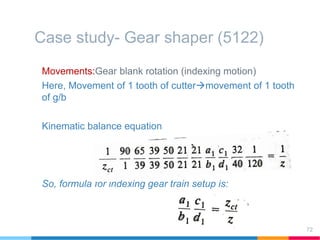

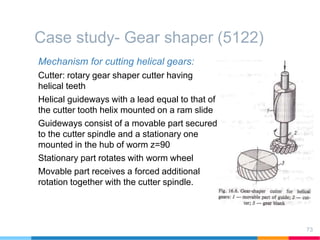

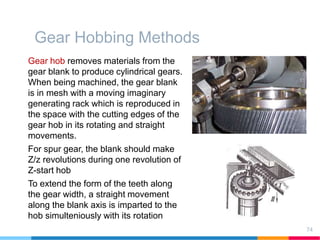

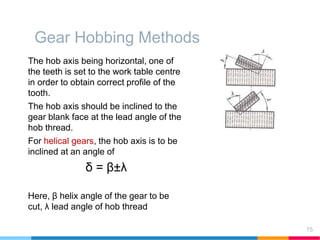

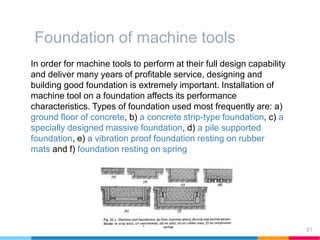

The document provides an overview of machine tools, focusing on types such as grinding machines, micro-finishing machines, and gear cutting machines, among others. It details the principles, movements, specifications, and working mechanisms involved in these tools, describing their applications in machining metal and other materials. Additionally, case studies explore specific machines, offering insights into their operation, features, and performance metrics.