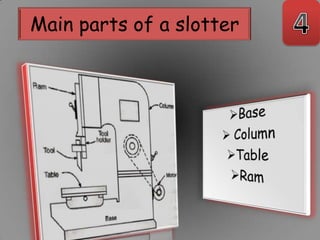

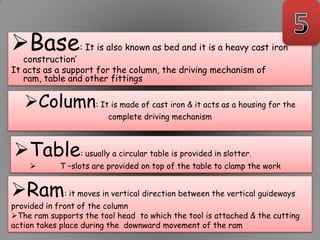

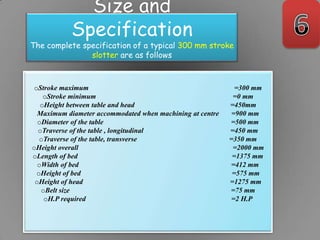

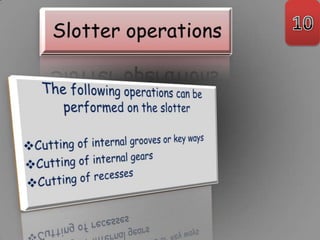

The document summarizes the main parts and specifications of a slotting machine. A slotting machine has a vertical ram and rotary table that allows for vertical cutting movement. The main parts include a base, column, table, and ram. The ram moves vertically to perform the cutting, guided by the column. Typical specifications for a 300mm stroke slotter include a 300mm maximum stroke, 450mm height between table and head, and dimensions for the table, bed, and overall machine. It is belt driven and requires 2HP power.