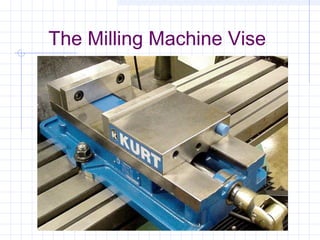

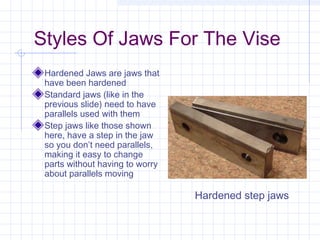

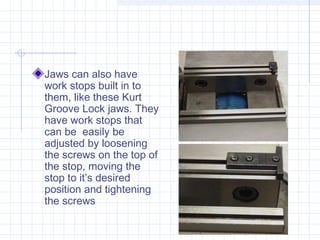

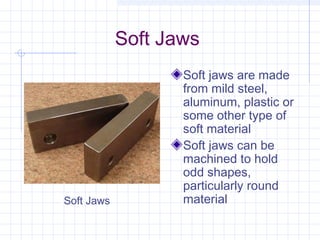

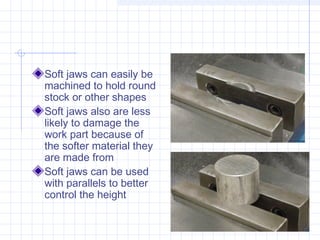

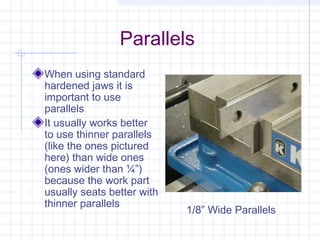

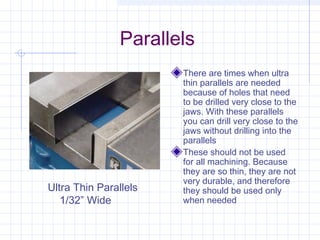

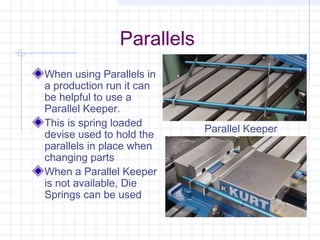

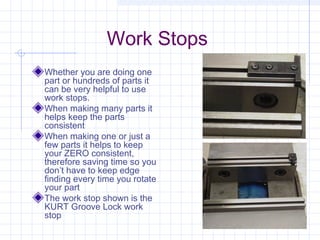

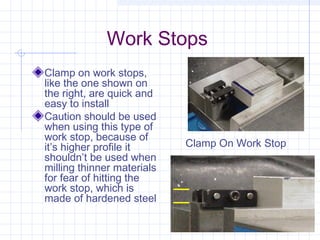

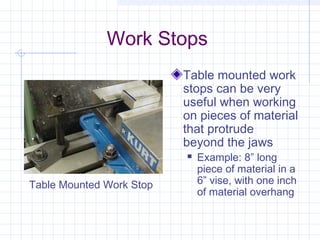

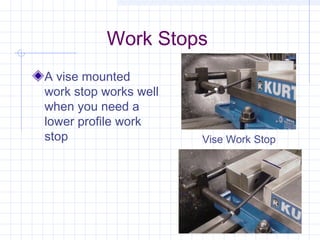

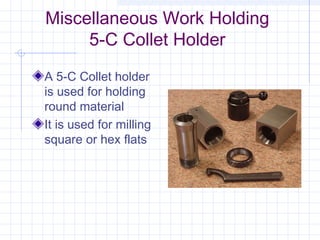

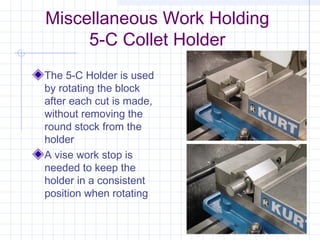

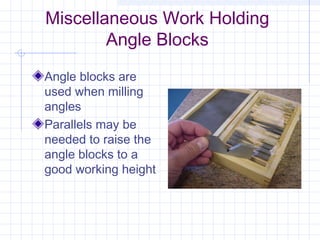

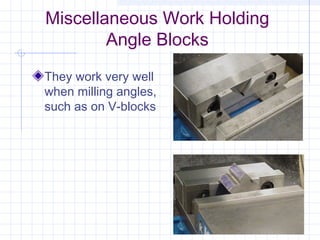

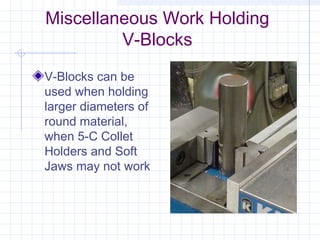

This document discusses various methods for work holding on milling machines. It describes milling vises, soft jaws, parallels, and work stops as basic styles of work holding. It provides examples of different types of jaws, such as hardened jaws, standard jaws, step jaws, and jaws with built-in work stops. It also discusses uses of soft jaws, parallels, parallel keepers, and different styles of work stops, including vise mounted, table mounted, and clamp on styles. Finally, it mentions other work holding methods like 5-C collet holders, angle blocks, and V-blocks.