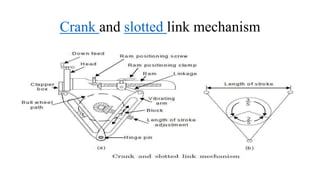

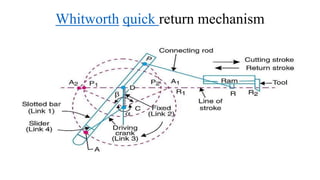

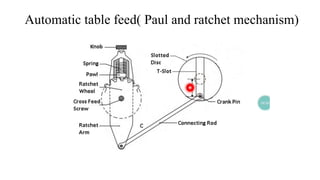

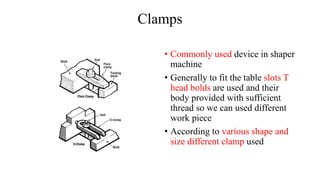

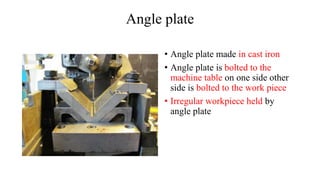

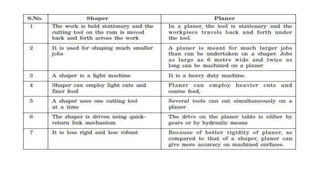

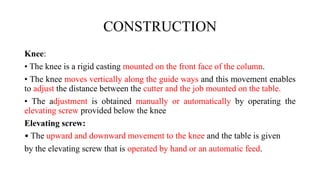

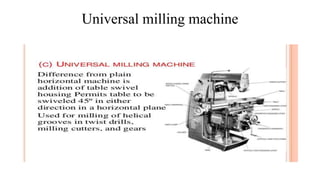

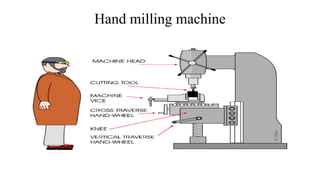

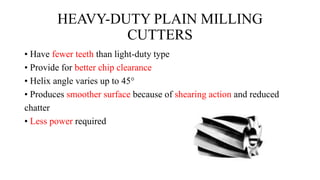

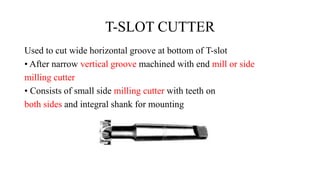

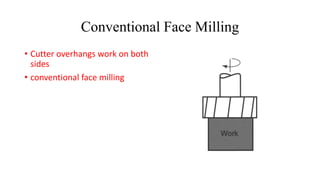

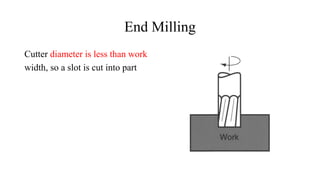

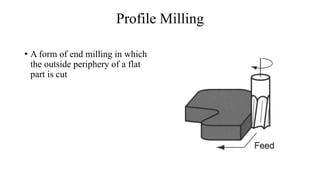

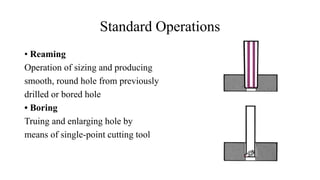

The document covers various machine tools used in manufacturing technology, focusing on shapers, milling machines, and drilling machines. It details their mechanisms, operations, classifications, and types of tools, as well as specific processes like gear cutting and finishing. Additionally, it outlines the construction and working principles of these machines, emphasizing their applications in precision machining and metal fabrication.