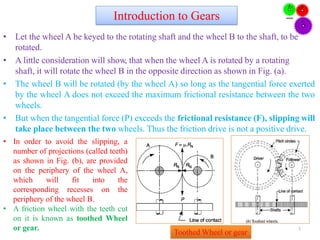

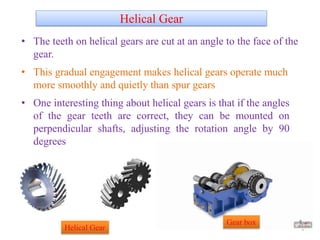

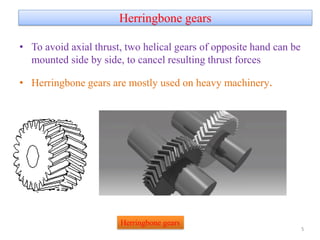

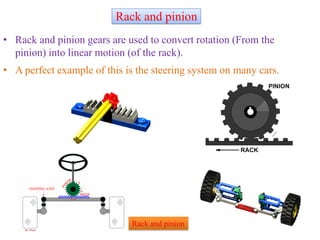

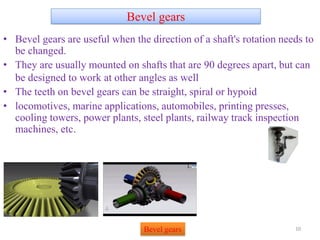

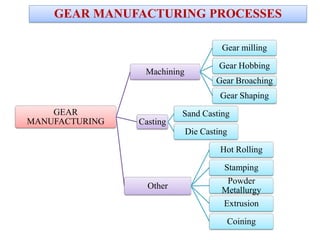

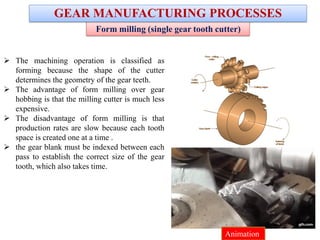

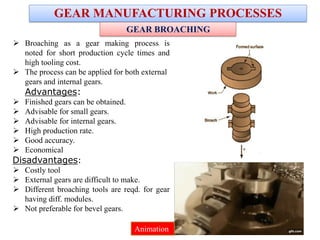

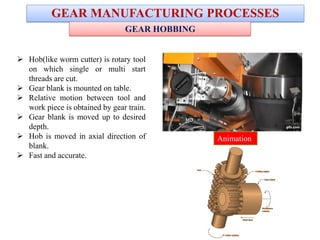

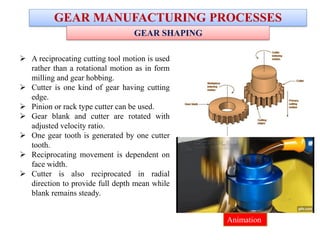

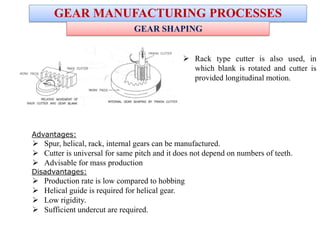

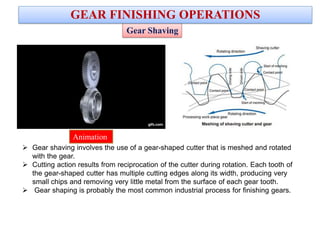

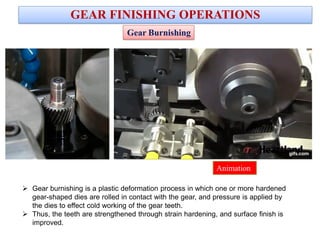

The document discusses various gear manufacturing processes. It describes gear generating processes like gear milling, hobbing, broaching and shaping. It provides details on gear finishing operations such as grinding, shaving, burnishing, honing and lapping. Various gear types are also covered, including spur gears, helical gears, herringbone gears, rack and pinion gears, worm gears and bevel gears. The document outlines the key steps, advantages and disadvantages of different gear manufacturing and finishing techniques.