The document lists and describes the main parts of a lathe machine:

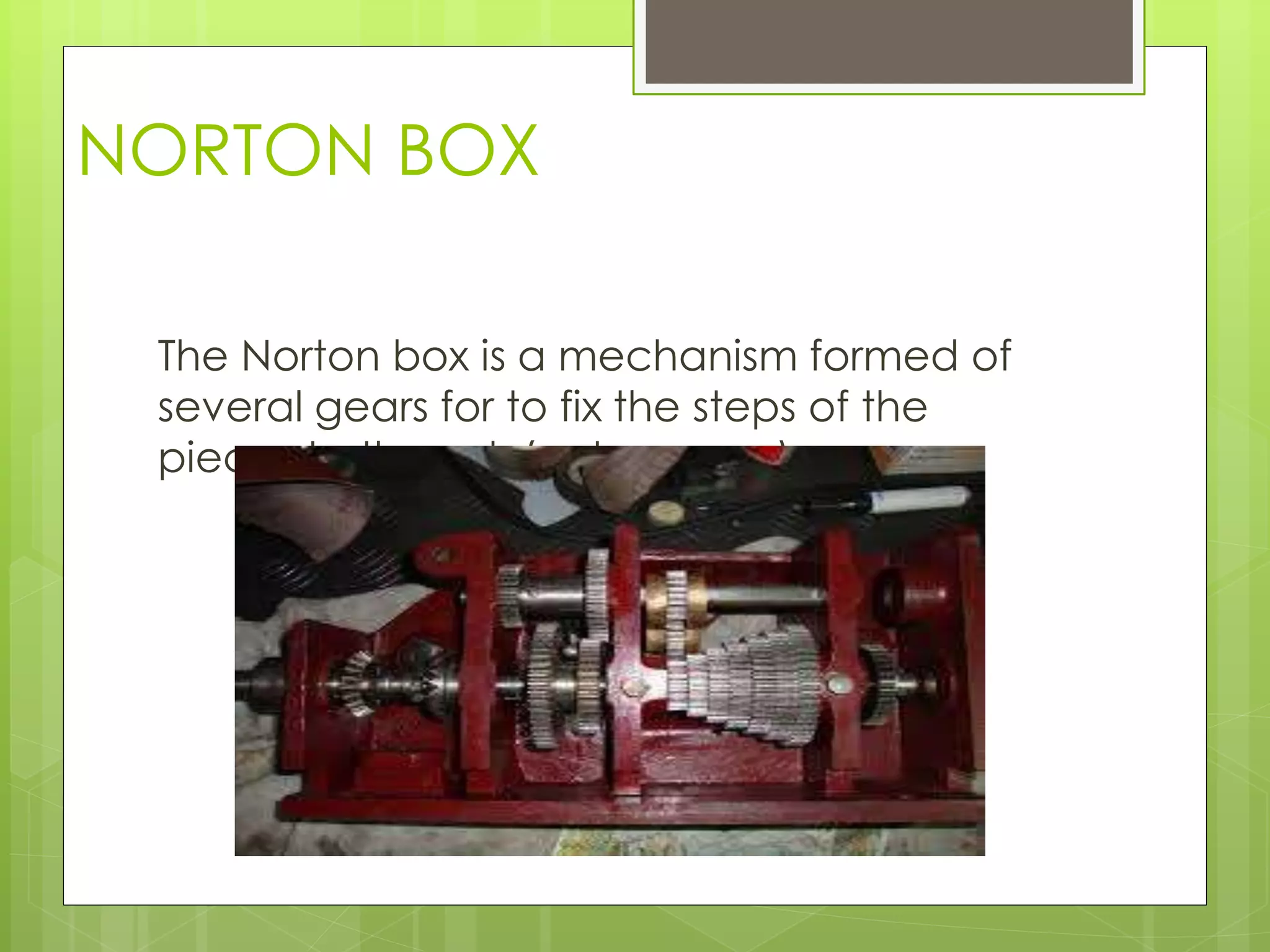

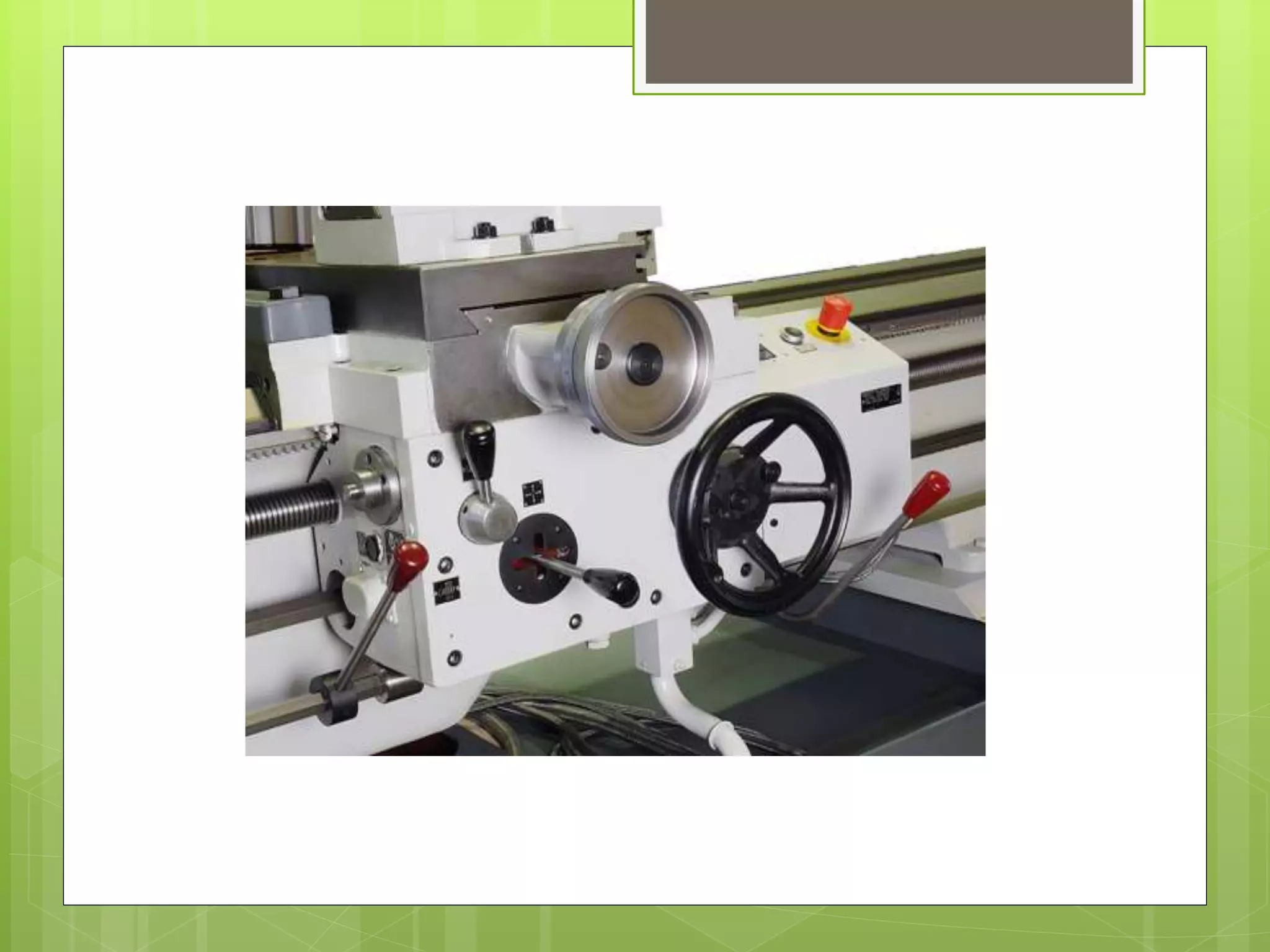

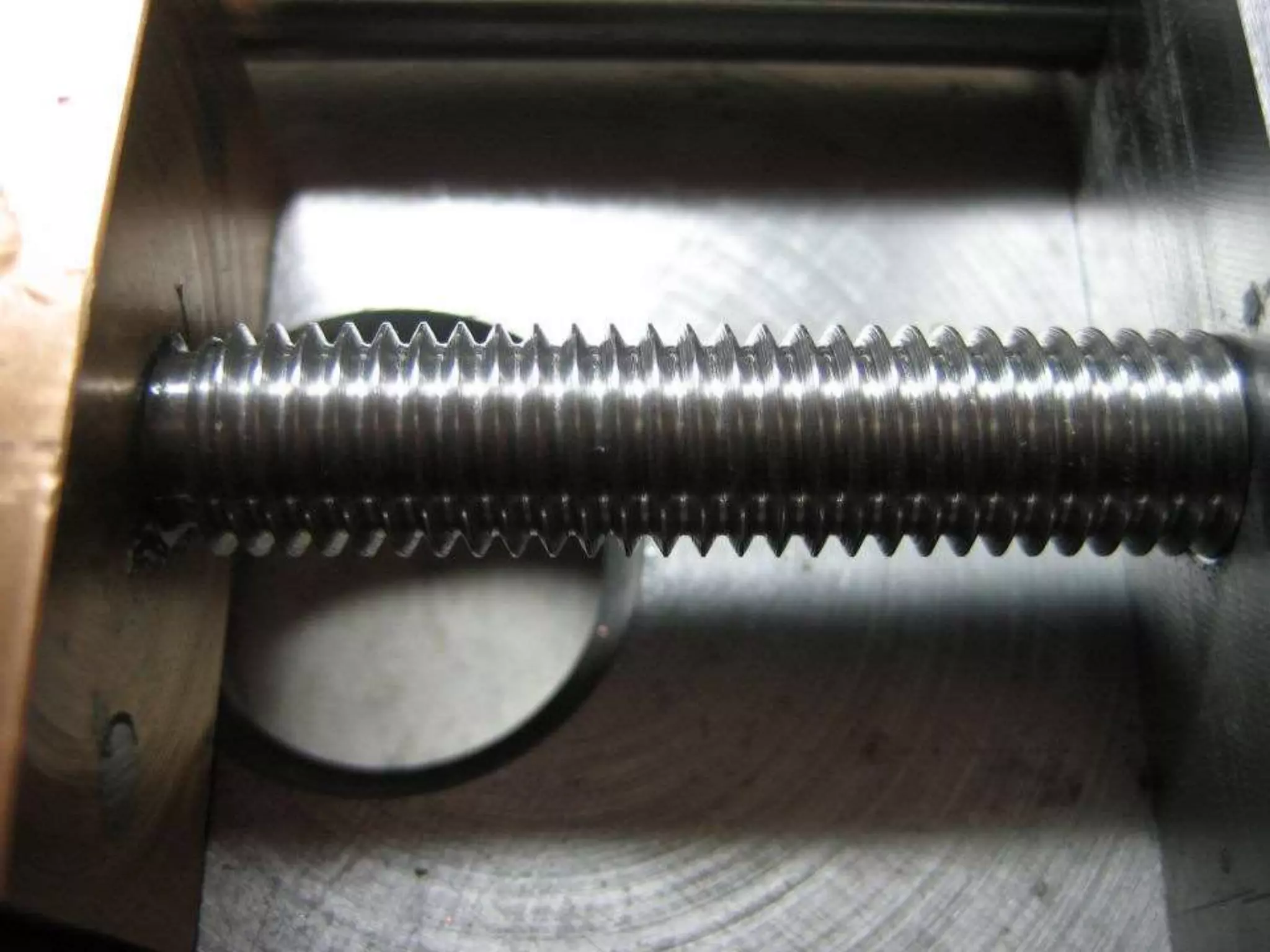

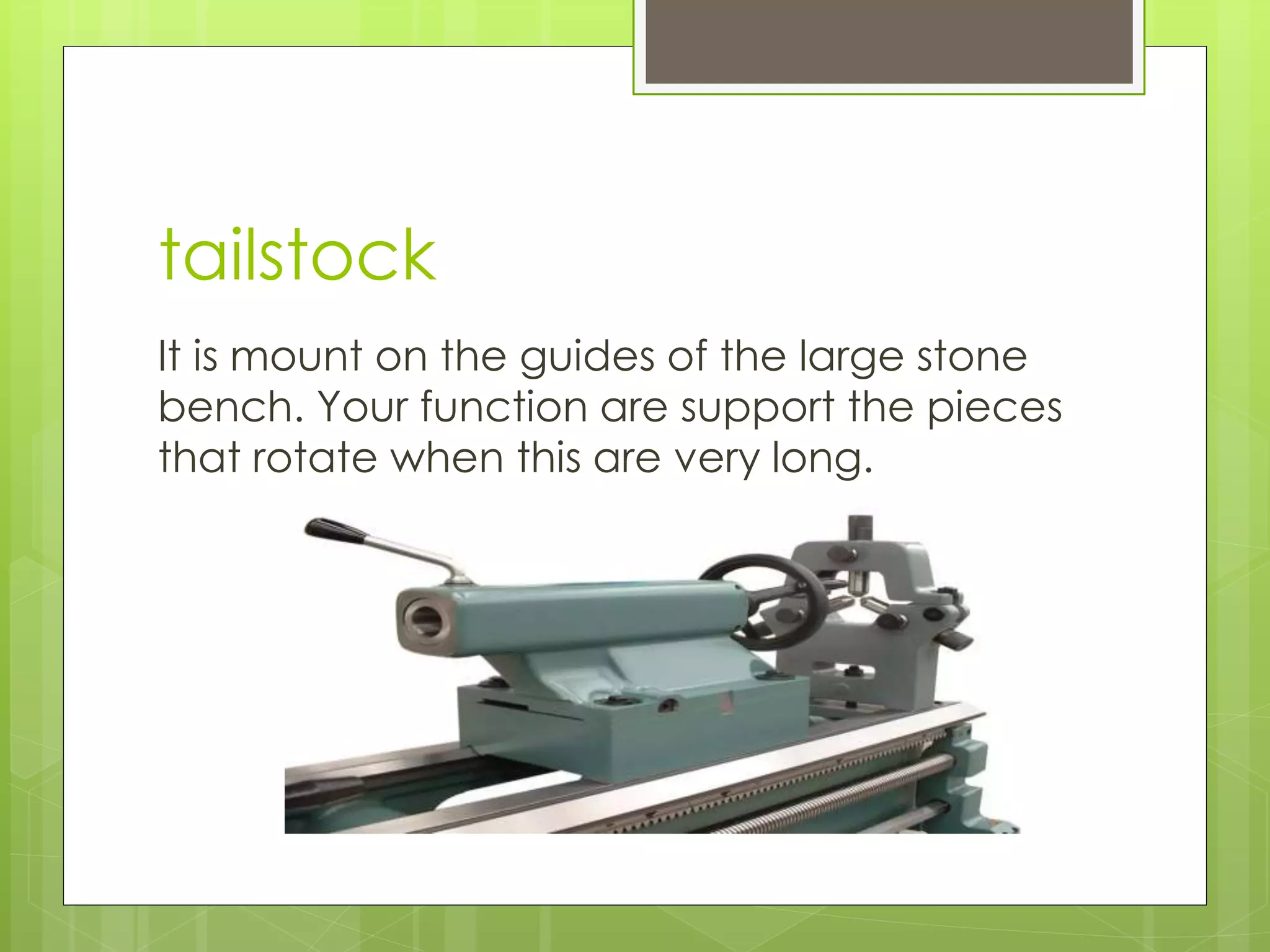

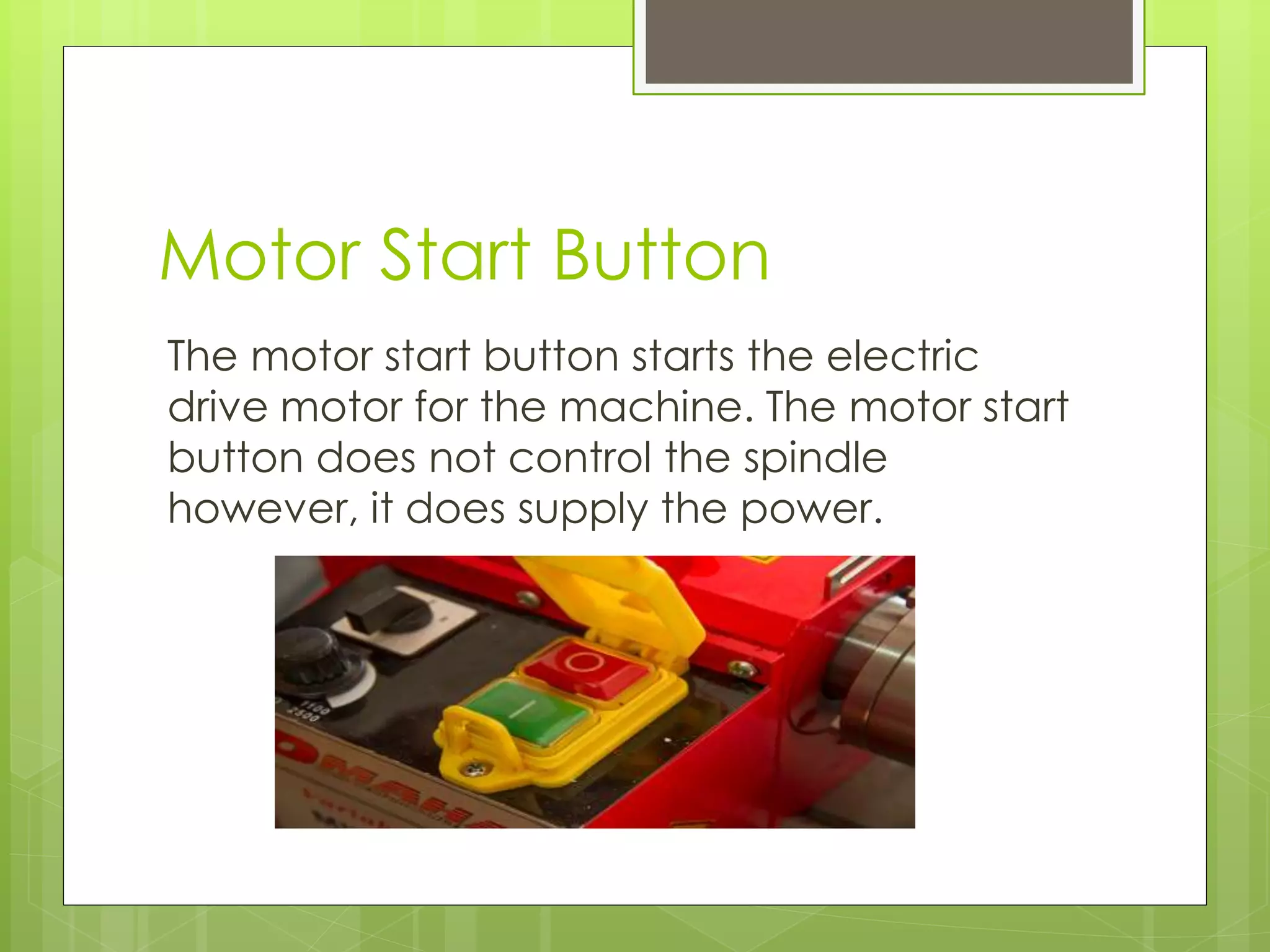

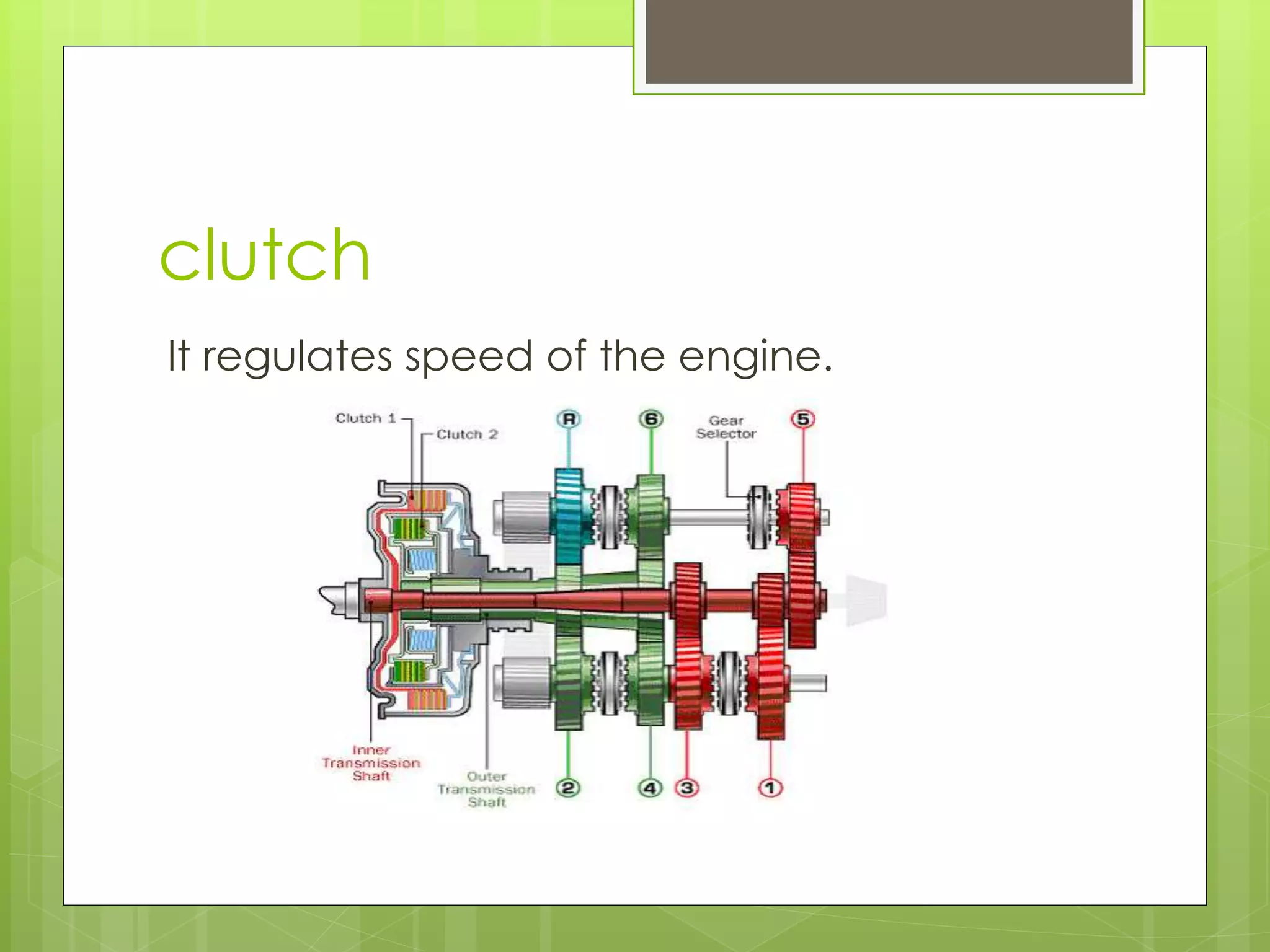

The Norton box fixes the steps for threading pieces. The large stone bench supports guides and has internal ribbing. The face plate supports and adjusts material. The longitudinal carriage supports and guides the cutting tool. The cross slide provides perpendicular motion for sideways tool movement. The splinde is a threaded bar that extends from the head to the counterpoint. The tailstock supports very long pieces that rotate. The brake stops the machine in emergencies. The spindle speed selector adjusts spindle speed. The emergency stop button cuts power. The motor start button powers the electric drive motor. The toolpost holds cutting tools. The clutch regulates the engine speed.