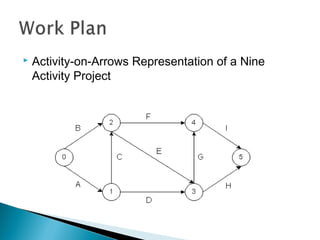

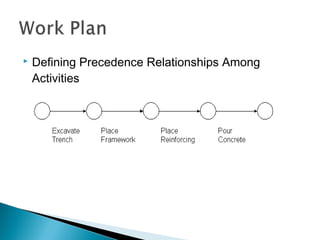

This document discusses integrating constructability reviews with lean construction and work planning. It describes how constructability must be considered early in the project life cycle during planning, design, procurement, and mobilization phases. Conducting detailed reviews of designs, models, specifications, and construction processes allows constructability specialists to identify issues like errors, unclear specifications, complex features, and aspects that will be difficult to bid or construct. The document also outlines key aspects of lean construction including maximizing value and reducing waste through techniques like supply chain management and just-in-time. Weekly work plans are identified as a tool to implement lean construction principles and production scheduling.