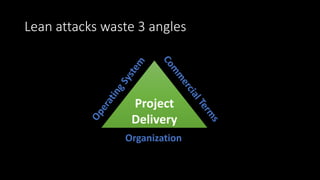

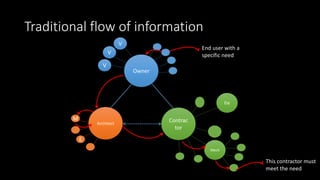

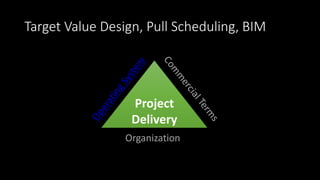

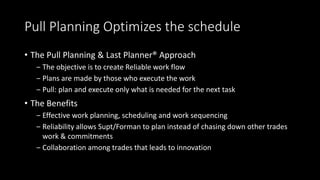

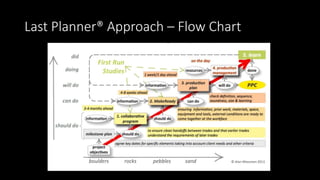

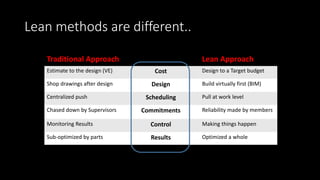

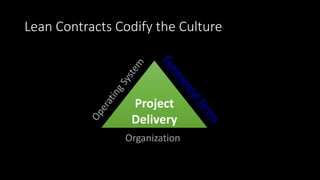

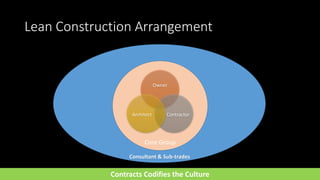

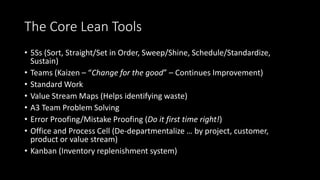

Lean construction aims to transform project management by removing waste and improving productivity, quality, schedules and costs. It draws from lean manufacturing principles to minimize non-value adding activities through tools like target value design, pull scheduling using the Last Planner System, and building information modeling (BIM). Integrated project delivery brings project teams together early through lean contracts to collaboratively design-to-budget and optimize the whole project, rather than sub-optimizing parts. This new approach requires transforming project culture from adversarial to relational and focusing on customer value and continuous improvement.