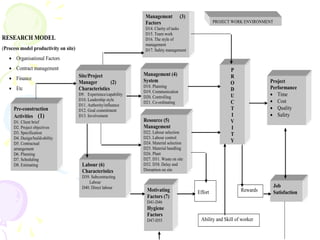

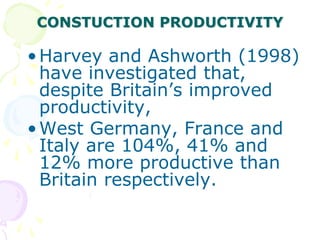

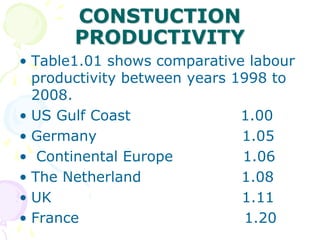

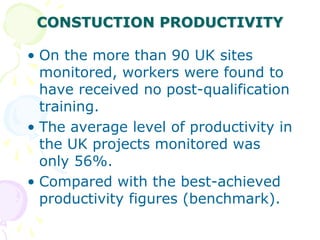

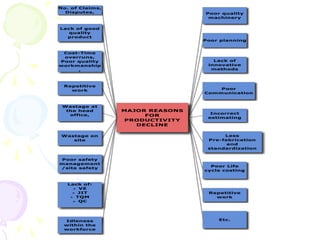

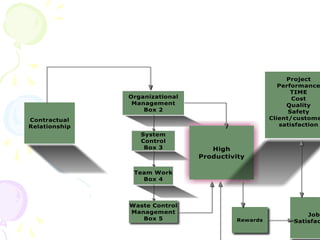

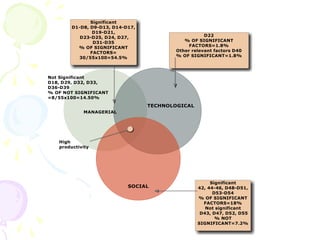

The document discusses construction productivity in the UK and other countries. It provides factors that impact productivity such as site/project management, resource management, labor characteristics, and motivation. Productivity in the UK construction industry has improved over the past decade but still lags countries like Germany and France. Reasons given for relatively lower UK productivity include issues with subcontracting, materials handling, training, and technology adoption. Improving areas like planning, prefabrication, and reducing waste could further increase construction productivity.