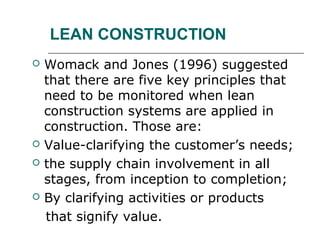

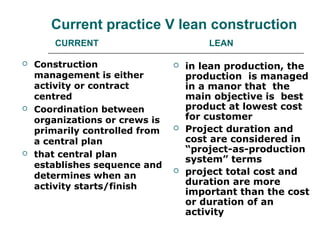

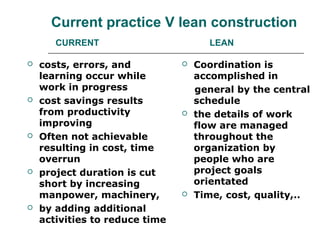

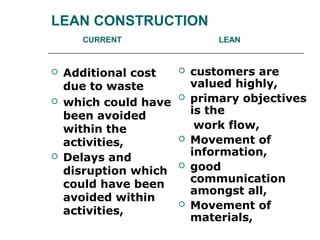

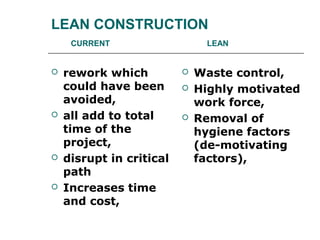

Lean construction is a process used in the construction industry to maximize value and minimize waste based on lean manufacturing principles. It utilizes techniques like supply chain management and just-in-time to improve information sharing and reduce waste. The Toyota Production System pioneered lean thinking by identifying and eliminating sources of waste to improve productivity, quality, and workforce satisfaction. Applying similar principles, lean construction aims to streamline project design and execution through prefabrication, continuous improvement, and collaboration across the project team.