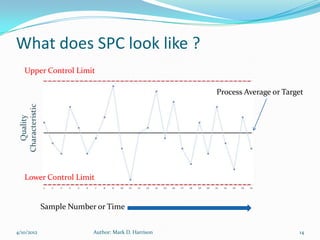

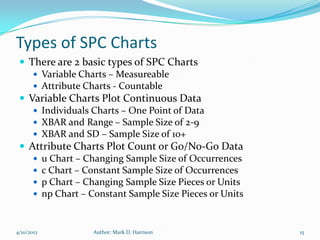

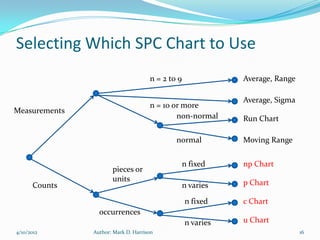

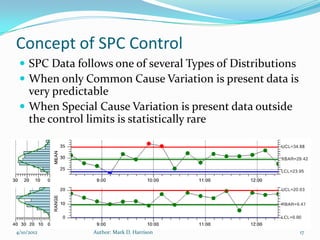

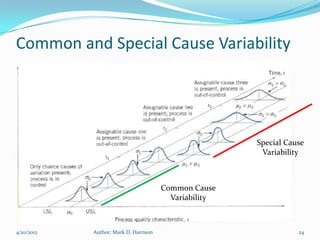

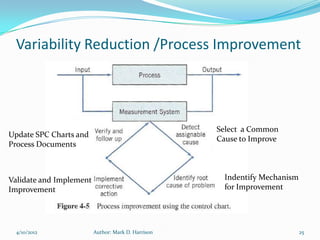

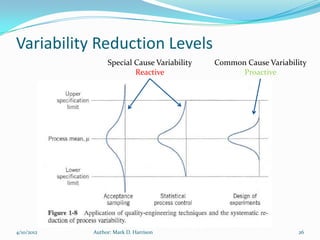

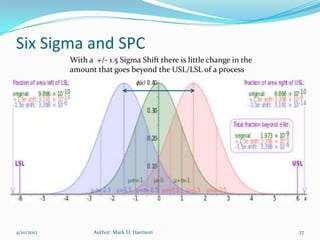

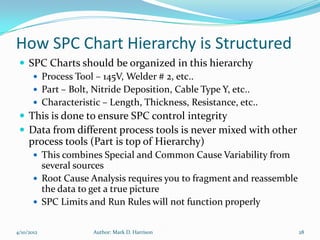

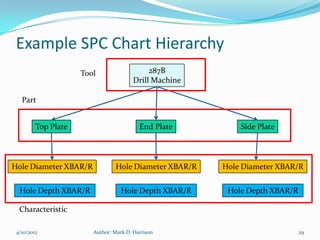

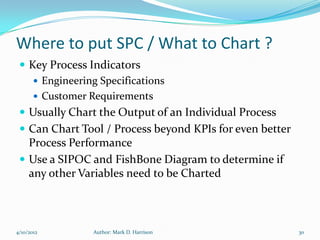

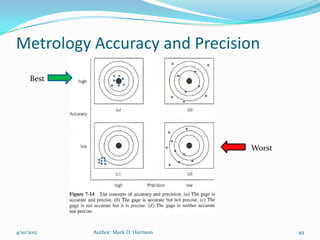

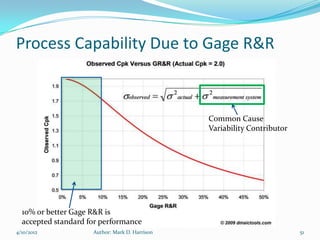

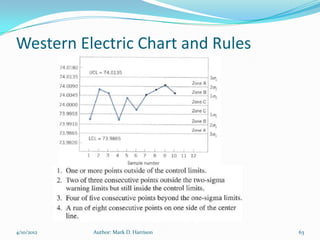

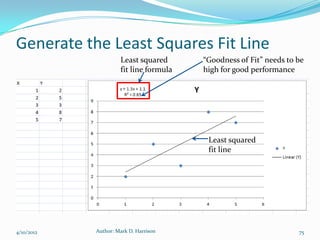

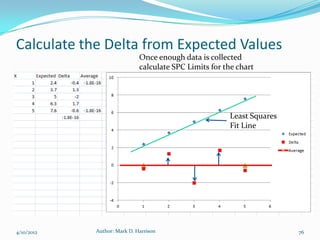

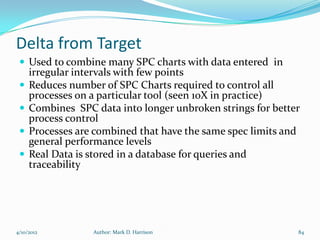

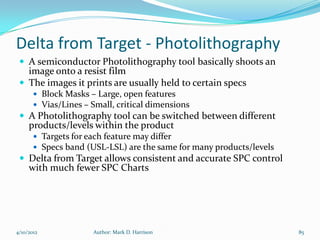

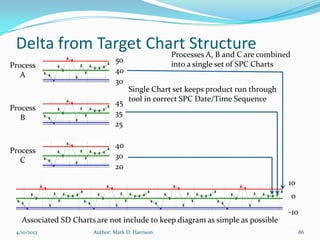

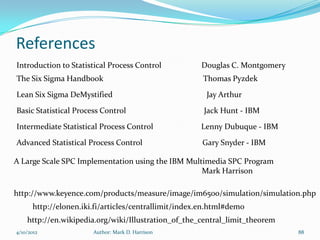

The document provides a comprehensive guide on implementing Statistical Process Control (SPC) to enhance process performance and integrate it into company culture. It outlines the definition, benefits, elements of a successful SPC program, and methods for reducing process variability. Additionally, it emphasizes the importance of management leadership, team involvement, employee education, and the use of various SPC charts to ensure effective monitoring and improvement of processes.