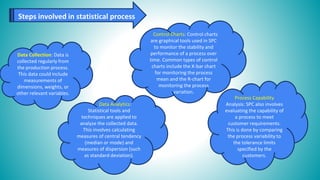

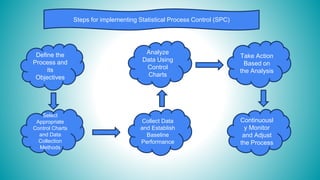

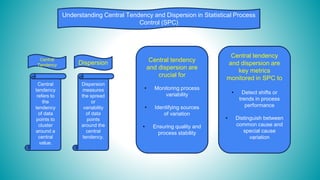

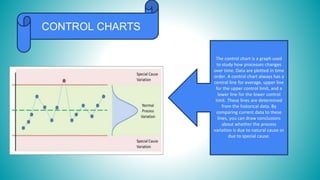

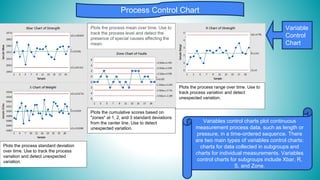

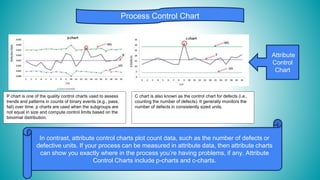

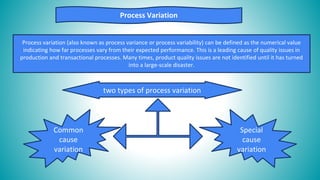

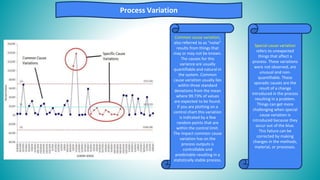

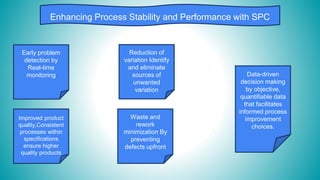

The document discusses Statistical Process Control (SPC), which uses statistical techniques to monitor and control manufacturing processes by distinguishing between normal variation due to common causes and abnormal variation due to special causes. SPC involves collecting process data, analyzing it using control charts, and taking corrective action if special causes of variation are detected to ensure processes are stable and operating as intended. The goal of SPC is to improve quality, reduce waste, and help manufacturers meet customer requirements.