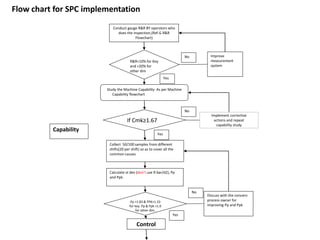

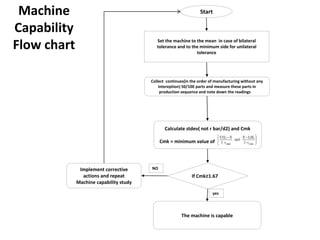

This flow chart outlines the steps for implementing statistical process control (SPC). It involves:

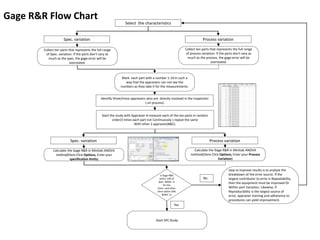

1) Conducting a gauge repeatability and reproducibility study to ensure measurement systems are adequate.

2) Calculating process capability indices like Cp, Cpk to determine if a process is capable.

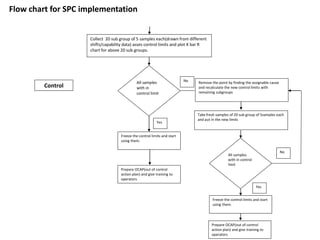

3) Collecting control chart data over multiple shifts to establish control limits.

4) Analyzing control chart data to identify processes that are in or out of control and determine appropriate corrective actions.