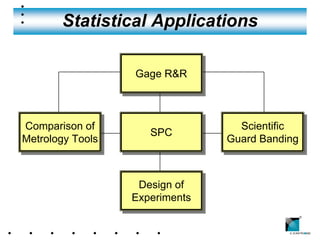

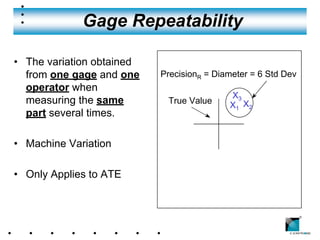

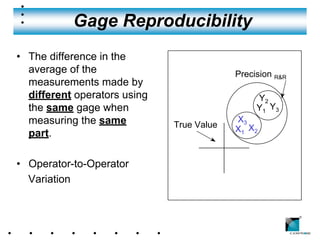

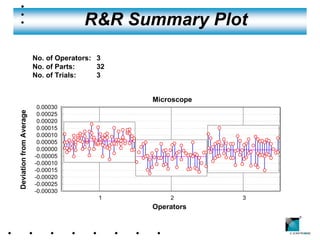

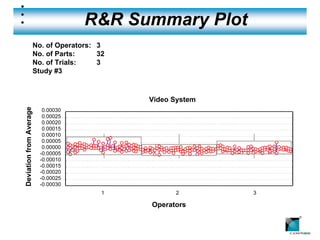

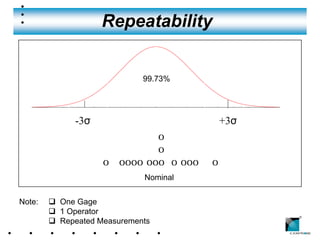

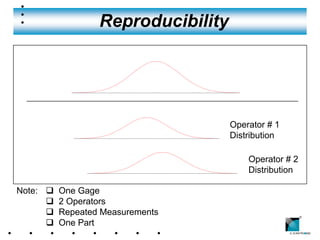

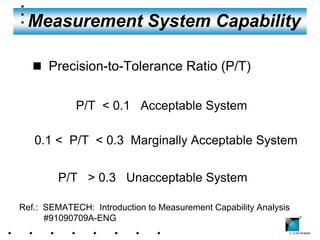

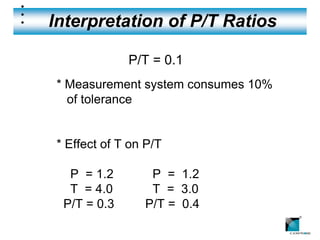

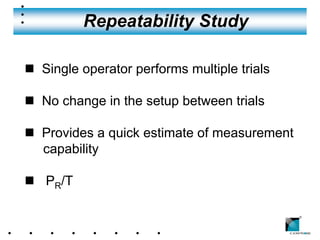

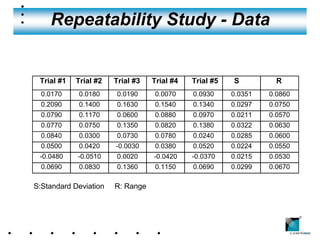

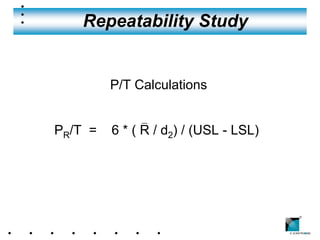

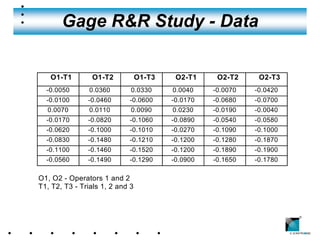

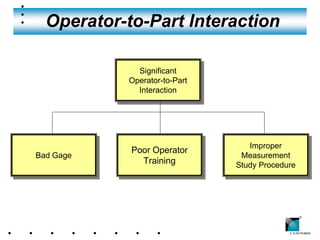

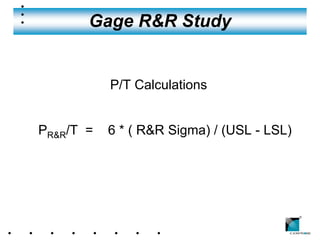

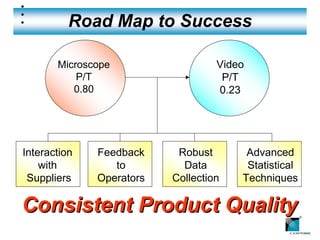

Hank Scutoski and Chander Sekar presented at the Southwest Test Conference on Gage R&R studies. They discussed how Gage R&R studies are important to understand measurement system capability before comparing or controlling manufacturing processes. The presentation covered key topics like repeatability, reproducibility, sources of variation, how to perform Gage R&R studies, and ways to analyze the data including calculating precision-to-tolerance ratios. The goal is to use statistical tools and Gage R&R results to improve processes and ensure consistent high quality products.