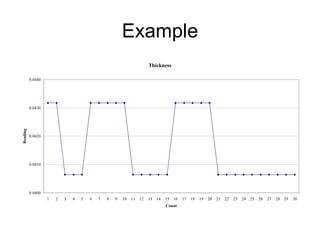

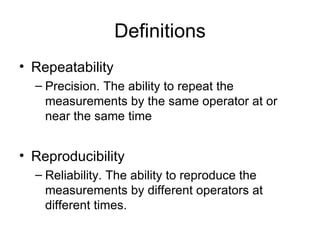

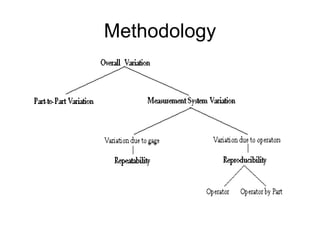

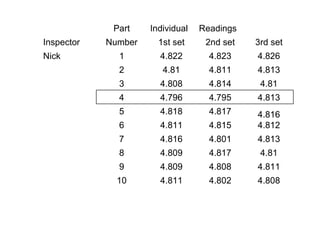

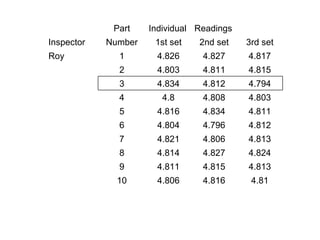

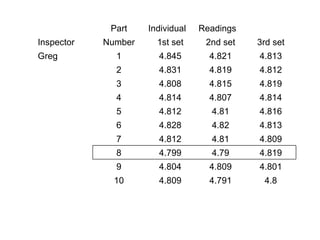

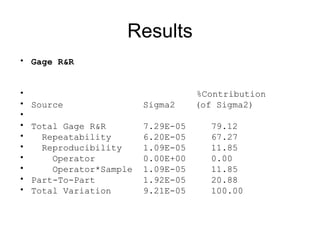

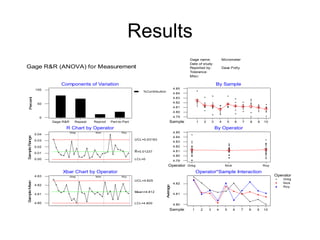

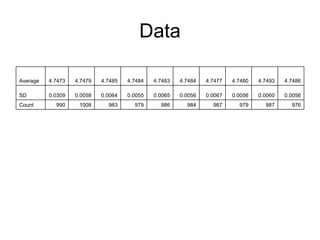

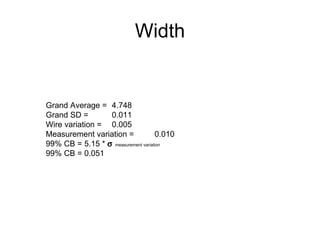

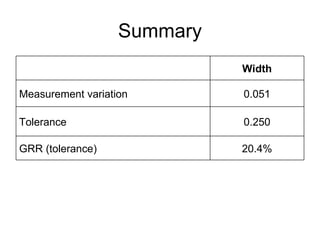

This document discusses gage repeatability and reproducibility (Gage R&R) studies. It defines gage R&R as a method to check if a gage is capable of precise and reliable measurements. It also defines key terms like repeatability, reproducibility, accuracy, and variations. The document provides examples of simple and more complex Gage R&R studies using a micrometer and width measurement. It analyzes the results in terms of variation contributions and control charts. Companies generally aim for gage variation to be less than 30% or 10% of total process variation depending on the gage's purpose.