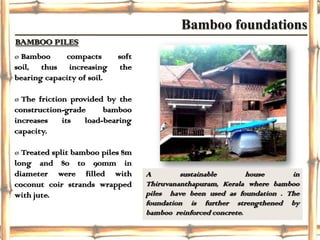

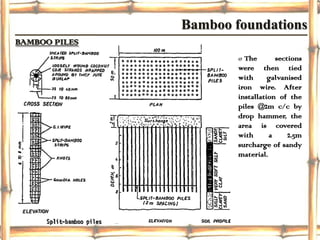

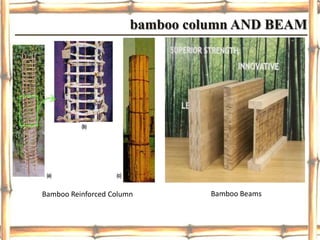

Bamboo is a versatile building material with several advantages such as strength, flexibility, earthquake resistance, low cost and minimal environmental impact. However, untreated bamboo has low durability. Various treatments like borax-boric acid preservation, neem oil treatment can improve the durability. Bamboo can be used for walls, foundations, columns, beams and roofing. It provides cost and energy benefits compared to concrete while maintaining structural strength. However, limitations include jointing techniques, flammability and lack of codified design guidance.