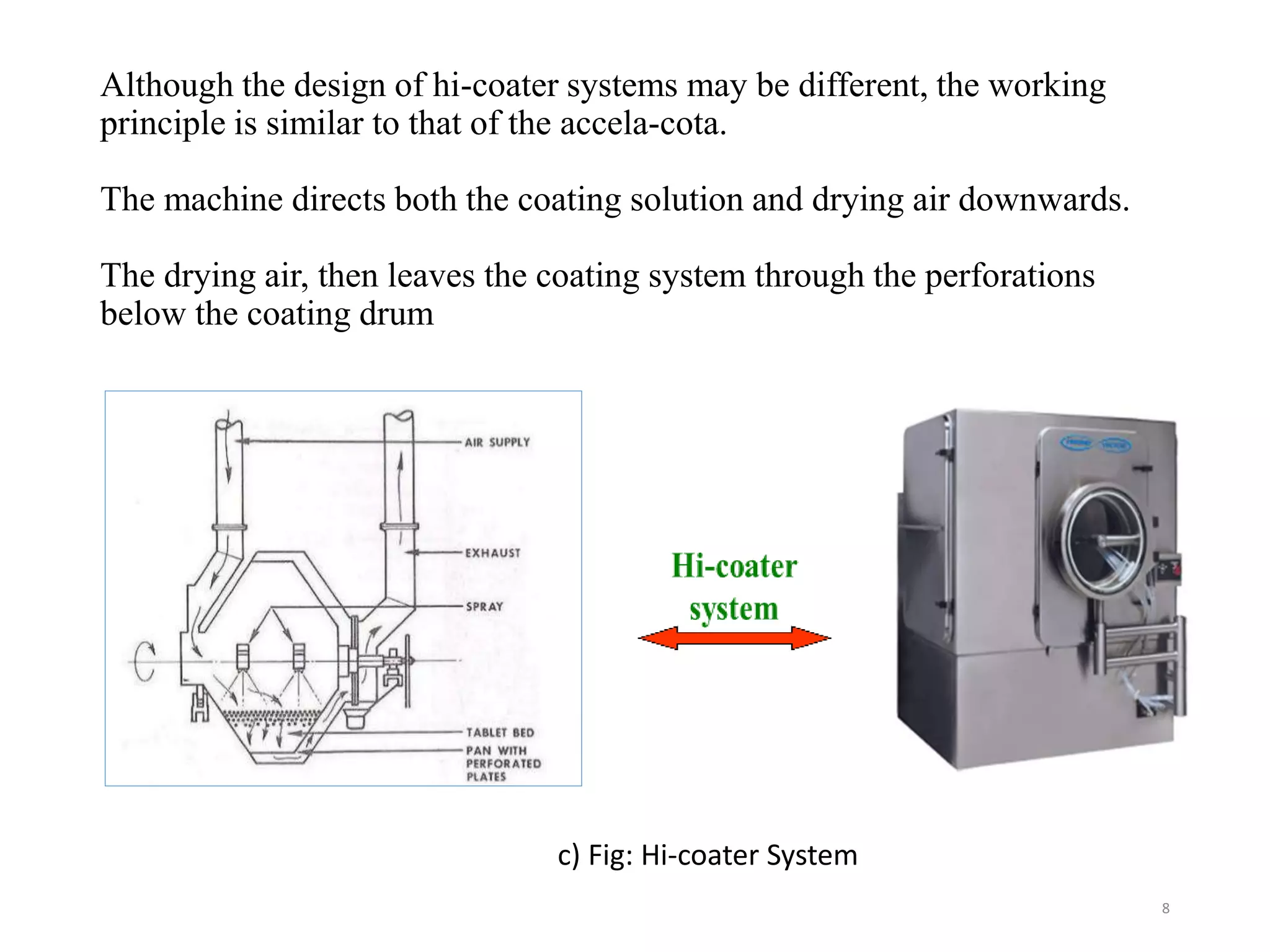

The document details the specifications and types of tablet coating machines produced by MD. Faysal, including various models, loading capacities, and motor specifications. It describes three main types of coating equipment: standard coating pans, perforated pan systems, and fluidized bed coaters, along with their operational principles. The document also references authoritative sources on pharmacy and coating technologies.