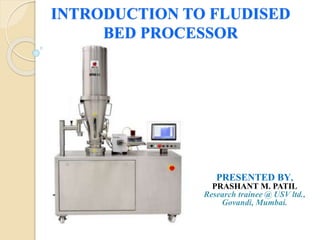

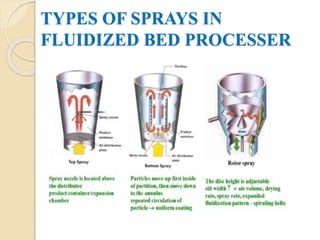

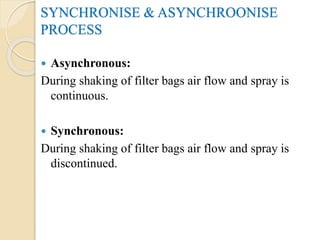

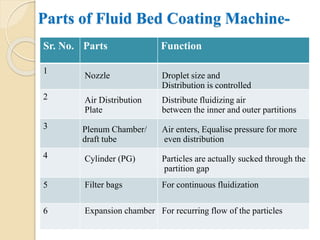

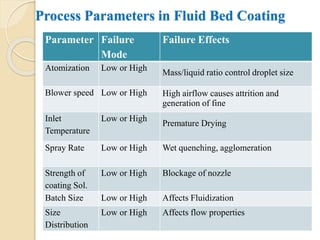

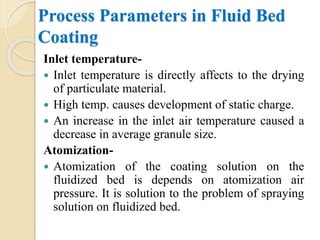

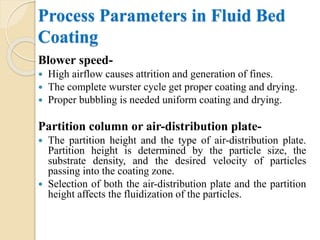

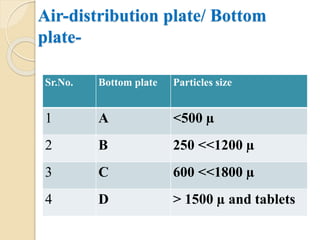

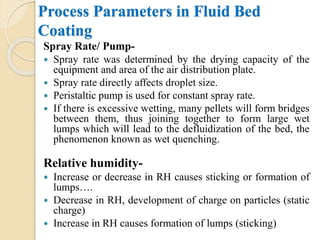

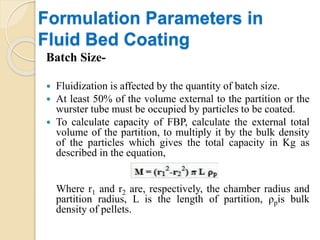

This document provides an introduction to fluidized bed processing, which involves coating, granulation, and drying of particulate materials. It describes the different types of spray processes in fluidized beds, including top spray, bottom spray, and tangential spray. Bottom spray processing, developed by Dr. Dale Wurster, is commonly used in pharmaceutical applications for coating uniformity. The document outlines the key components of a fluidized bed coater and discusses important process parameters like inlet temperature, spray rate, and batch size that can impact performance. Formulation factors like coating solution strength and batch size are also reviewed. Fluidized bed processing is used to improve drug properties like taste, appearance, and release characteristics.