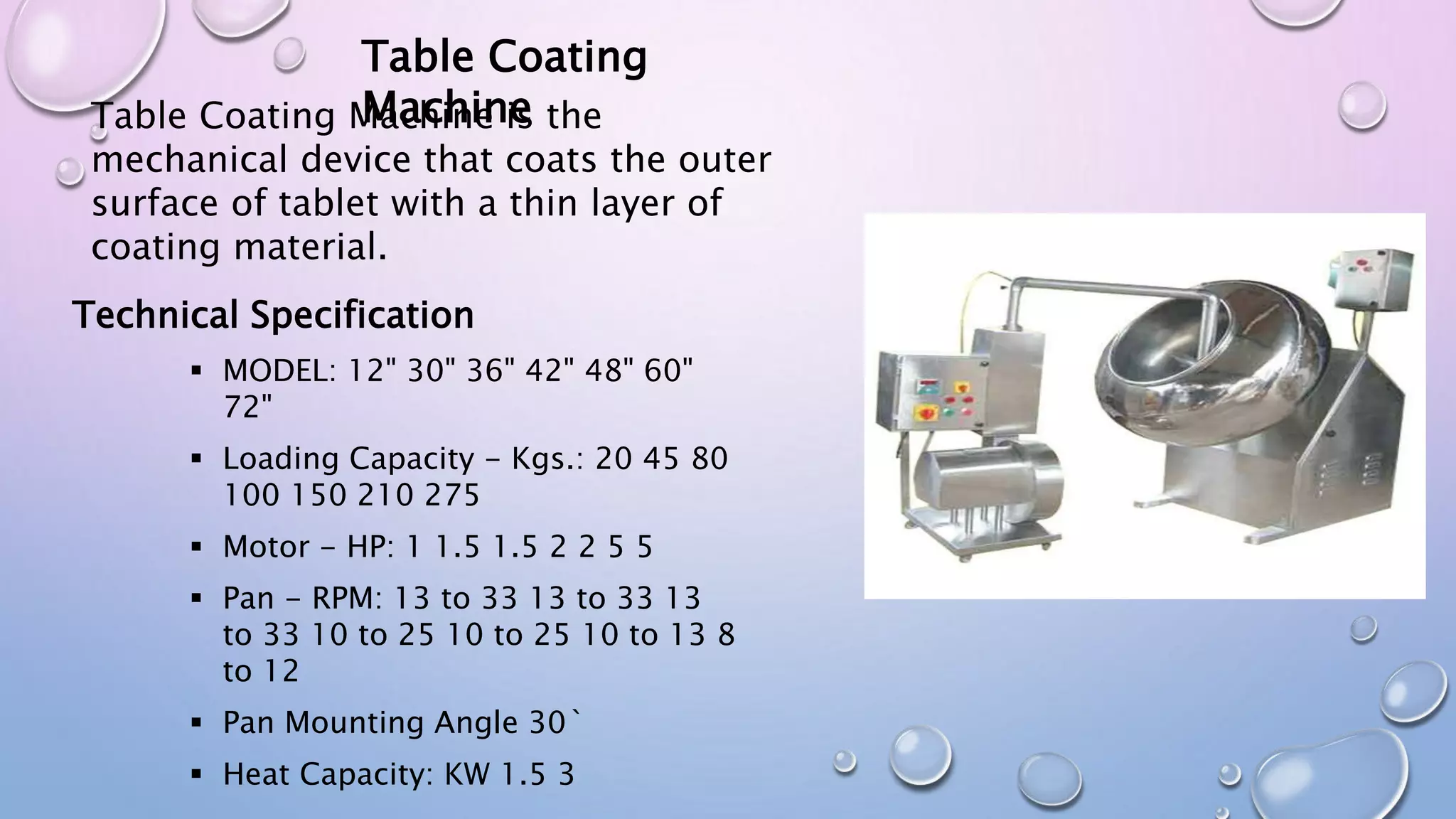

Tablet coating machines provide a thin outer layer or coating to tablets. They come in various sizes depending on loading capacity and motor power. The coatings are used to mask tastes and odors, provide protection, and control drug release. Common types of coatings include sugar, film, enteric, and controlled release. Coating components include polymers, solvents, plasticizers, opacifiers, and colors. Tablet coating machines include standard pans, perforated pans, and fluidized beds. Standard pans have a rotating metal pan to apply and dry coatings. Perforated and fluidized bed systems improve coating uniformity. Coatings provide benefits but also require significant capital costs and extraction systems.