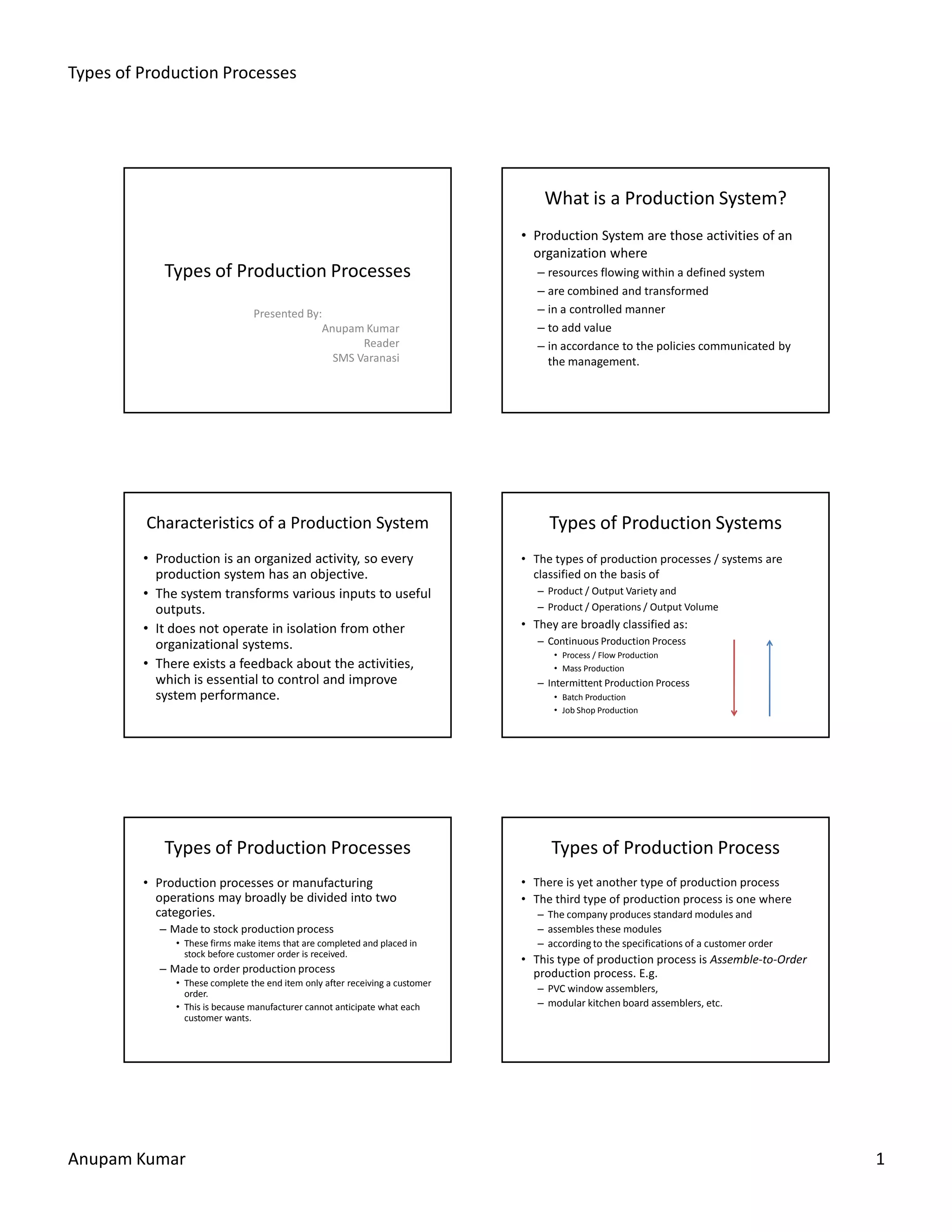

The document discusses different types of production processes. There are four main types: job shop production, batch production, mass production, and continuous/flow production. Job shop production involves unique custom products in low volumes. Batch production groups similar products into batches. Mass production focuses on high volumes of standardized products. Continuous production involves a linear and automated process with no backtracking.