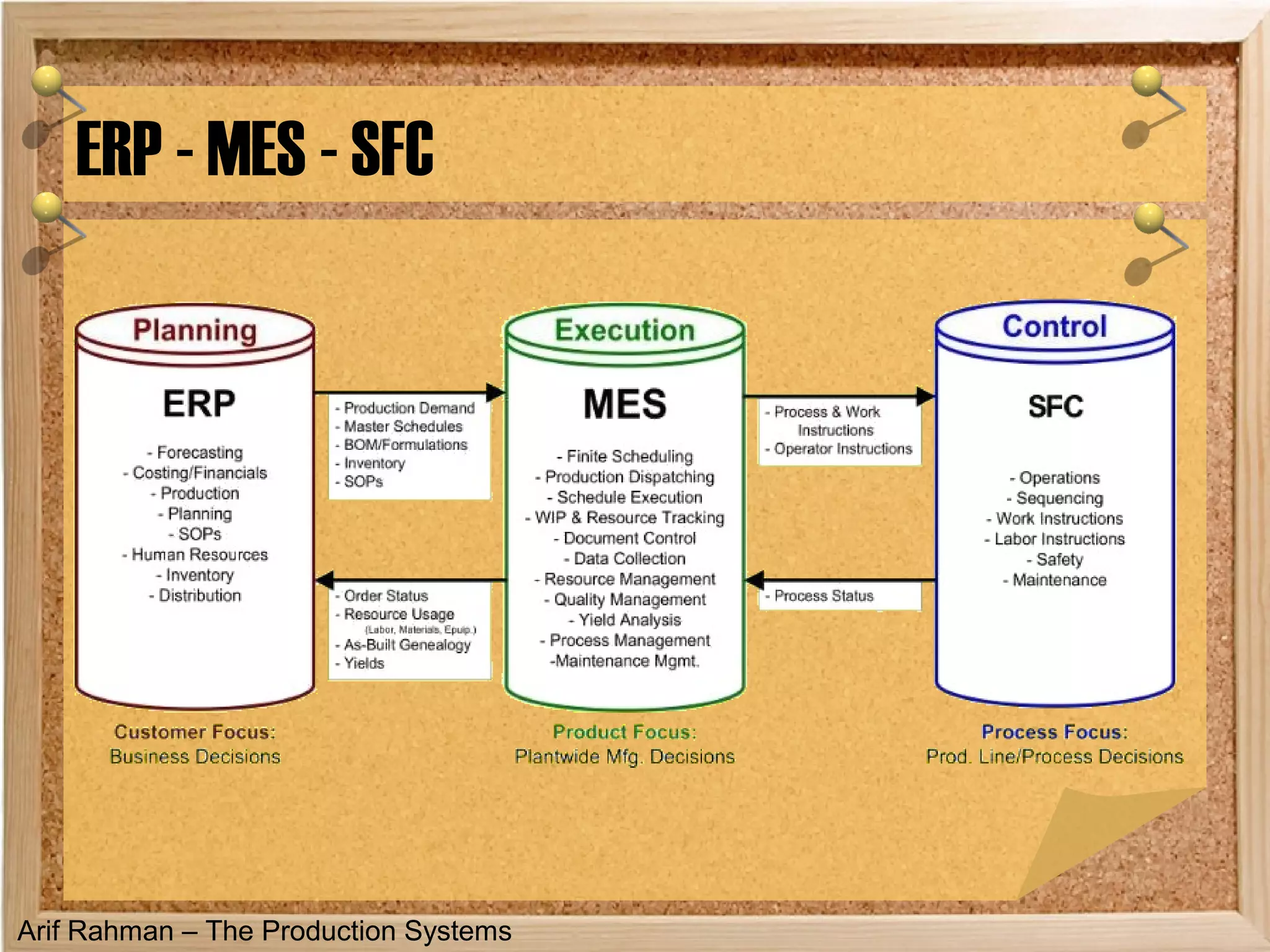

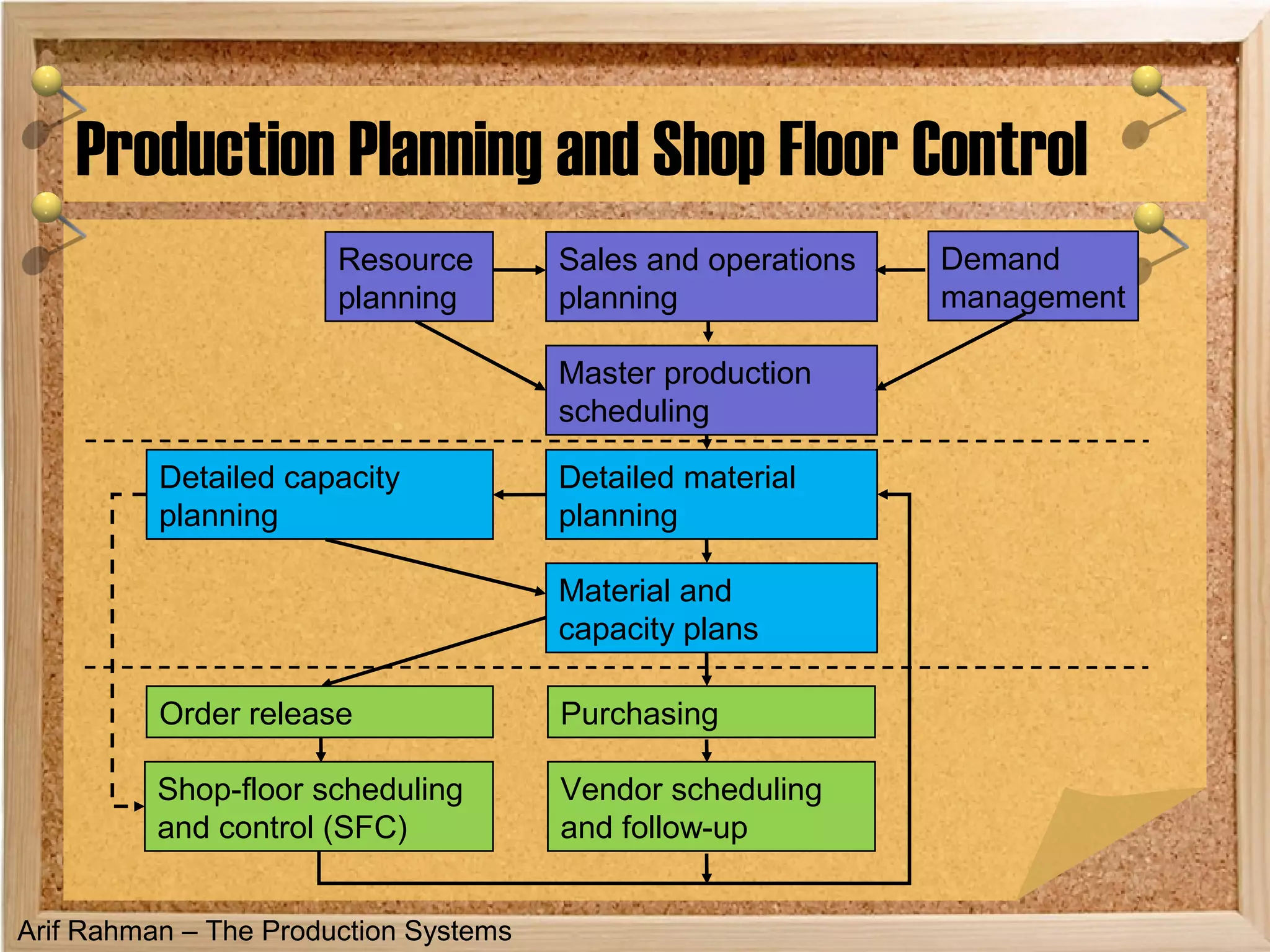

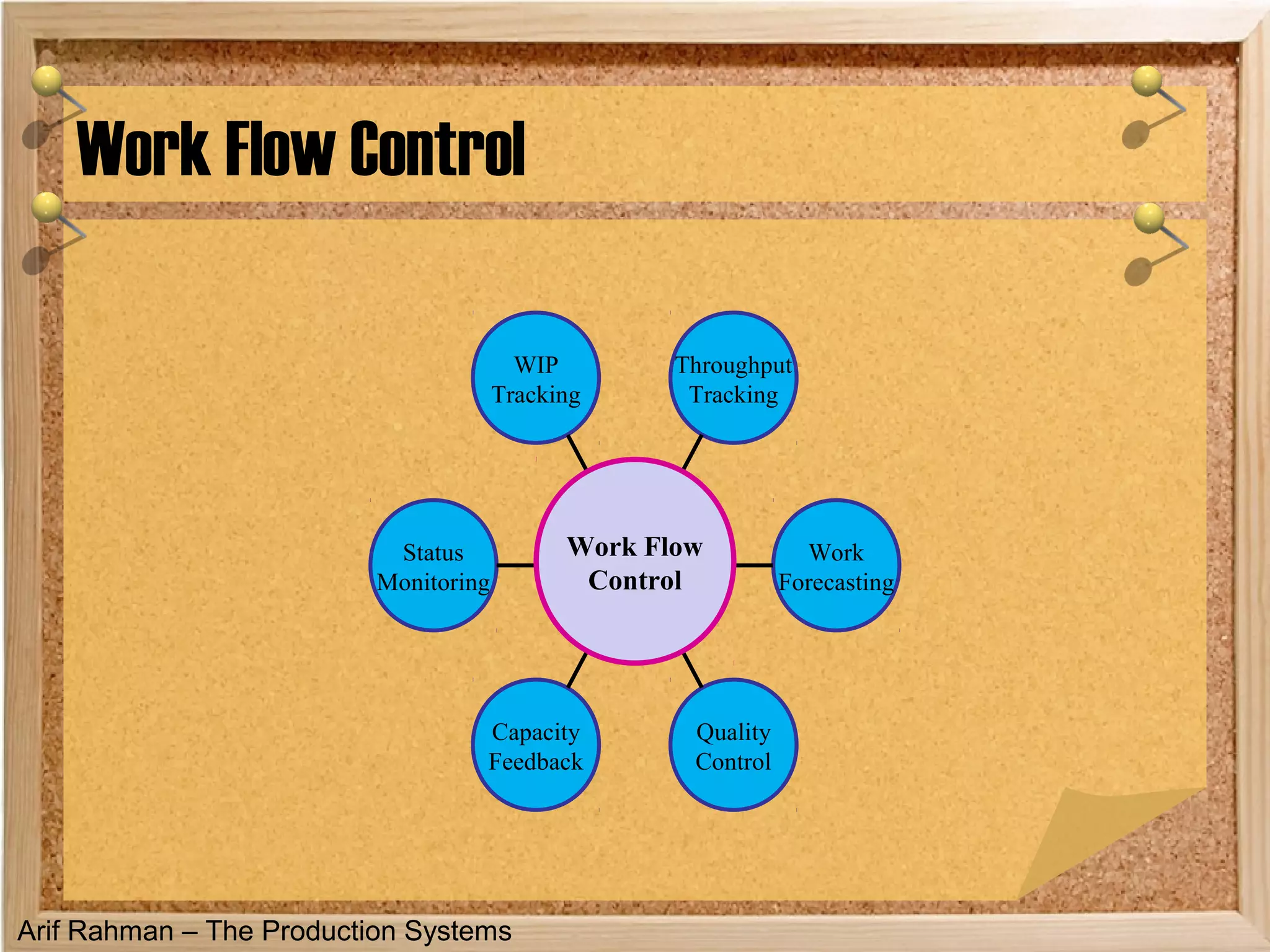

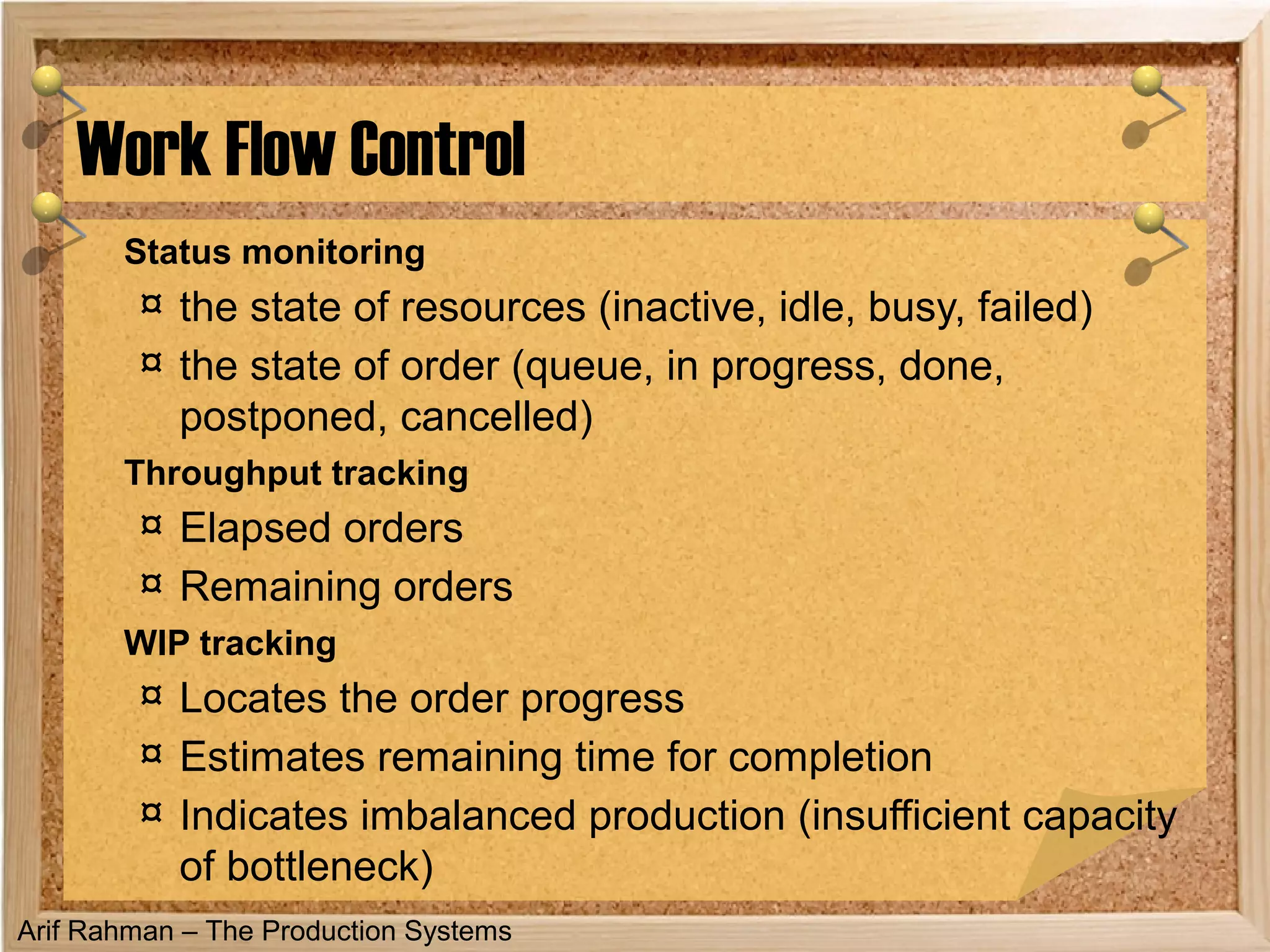

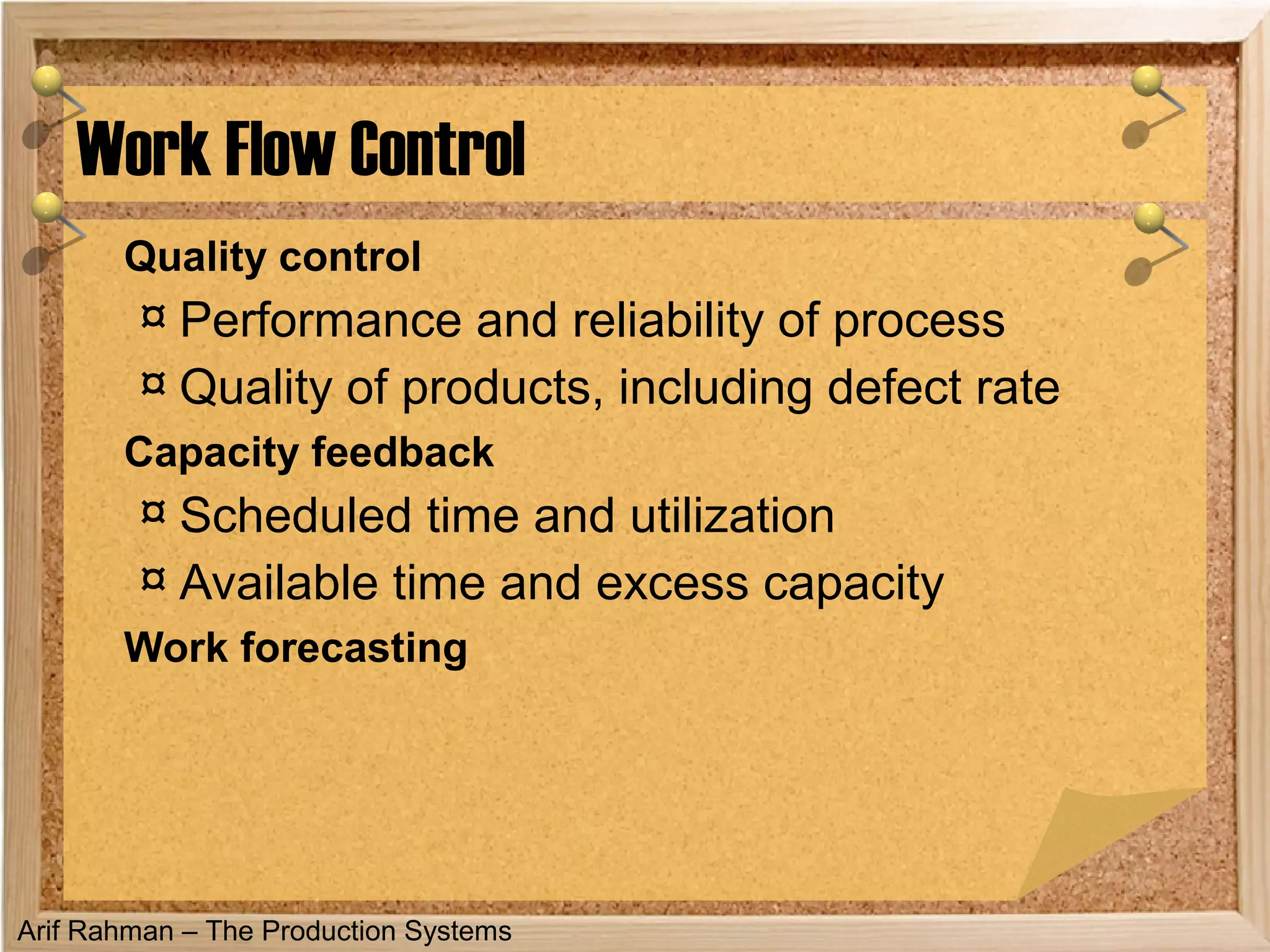

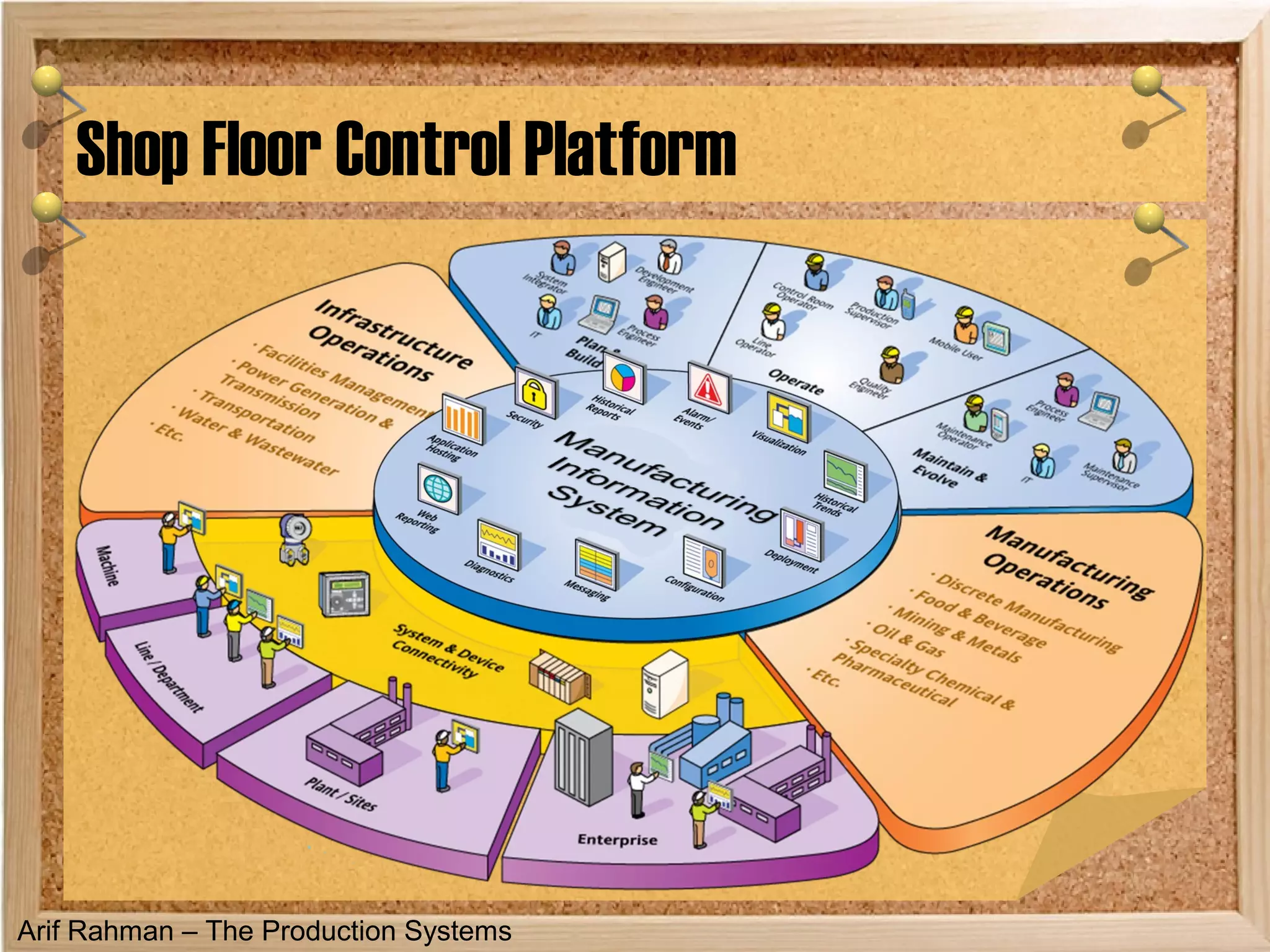

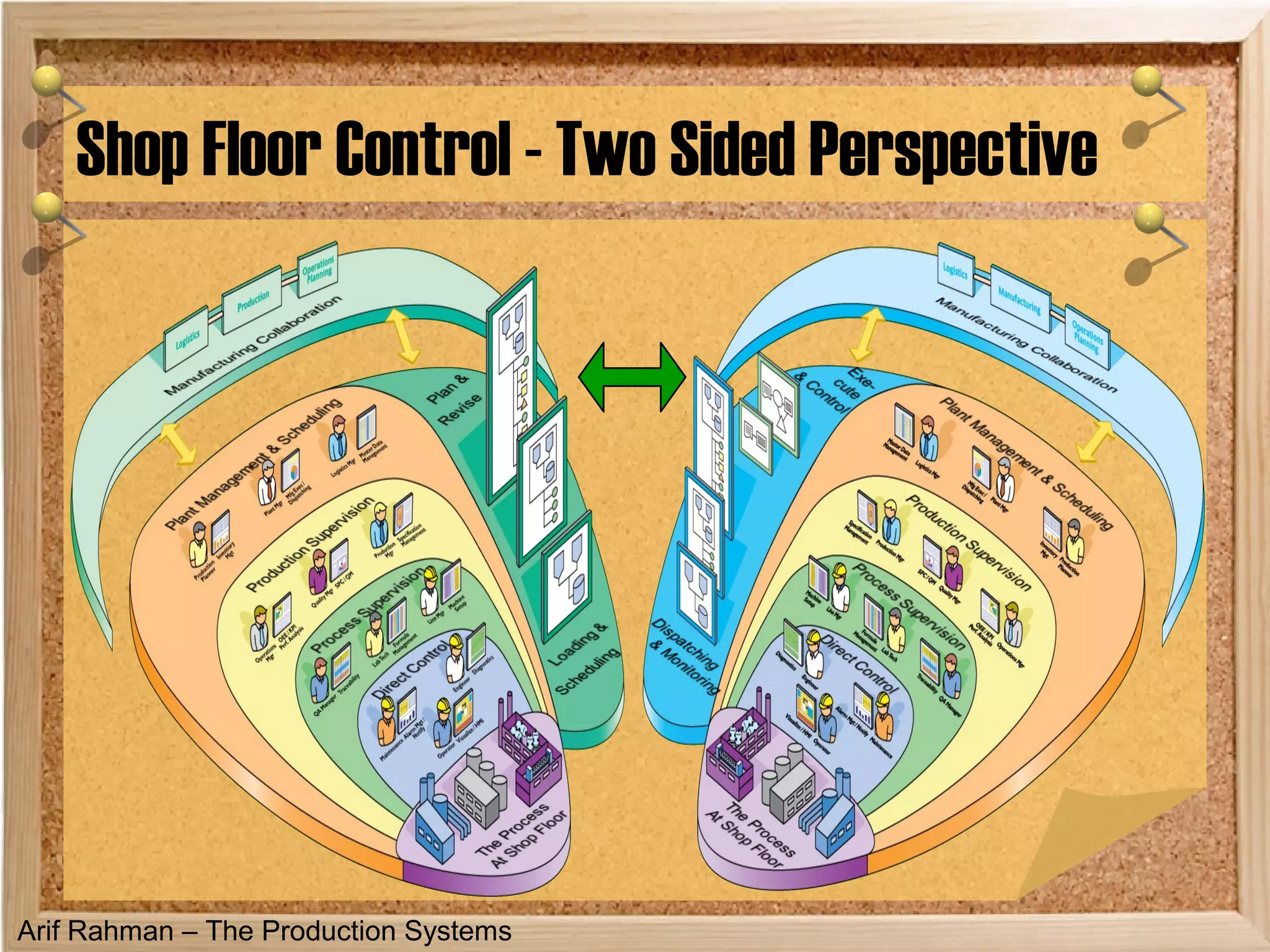

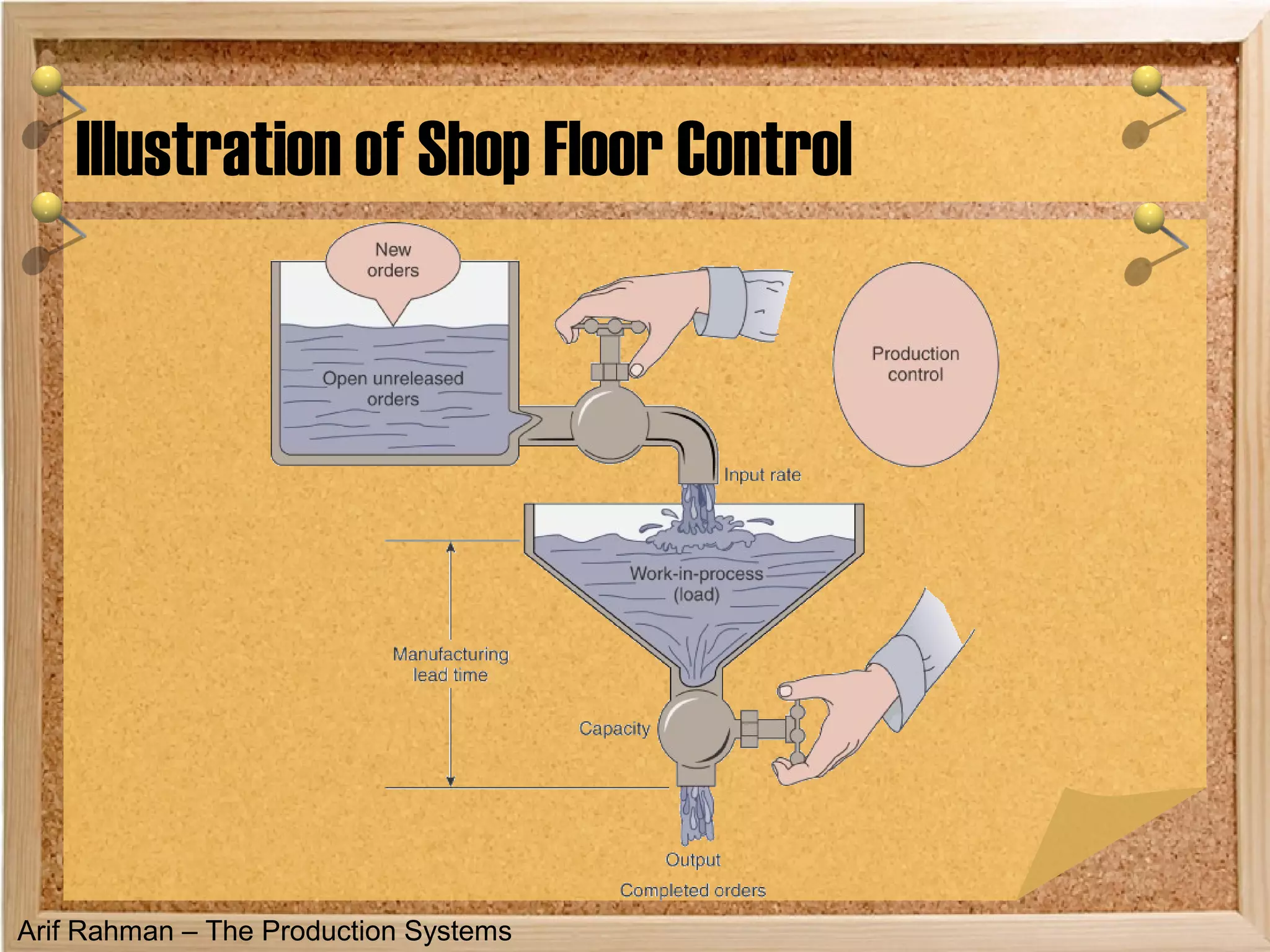

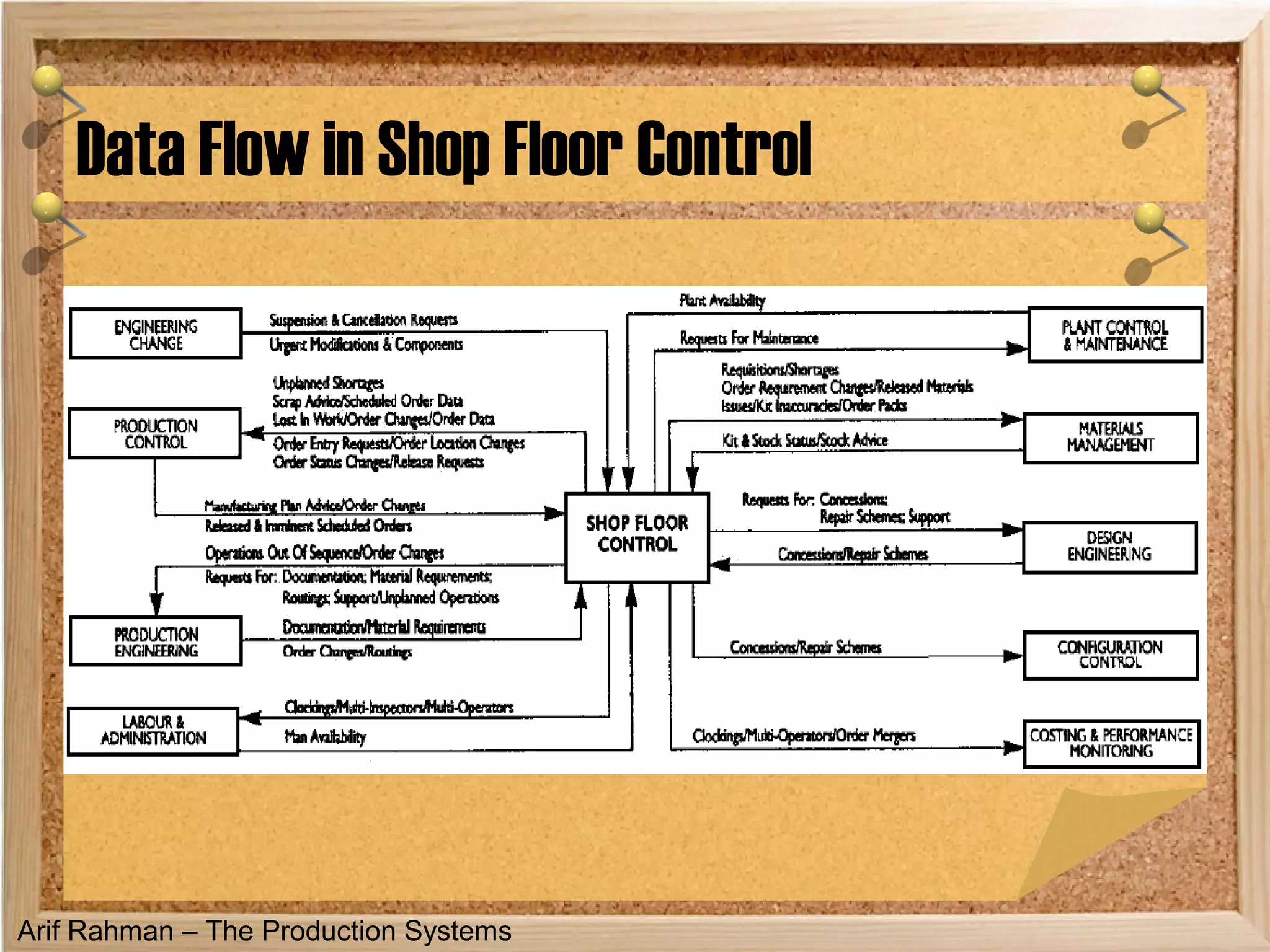

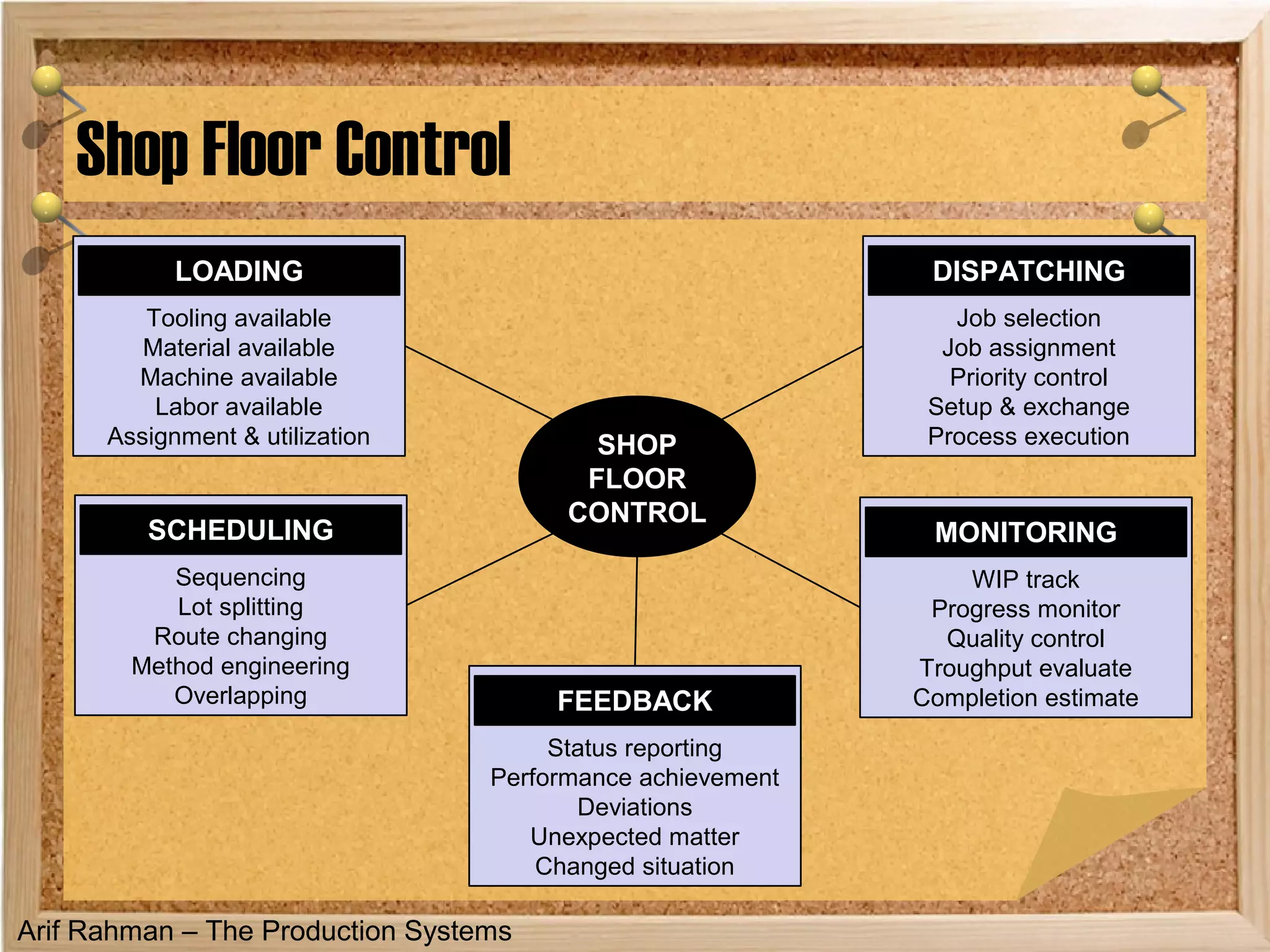

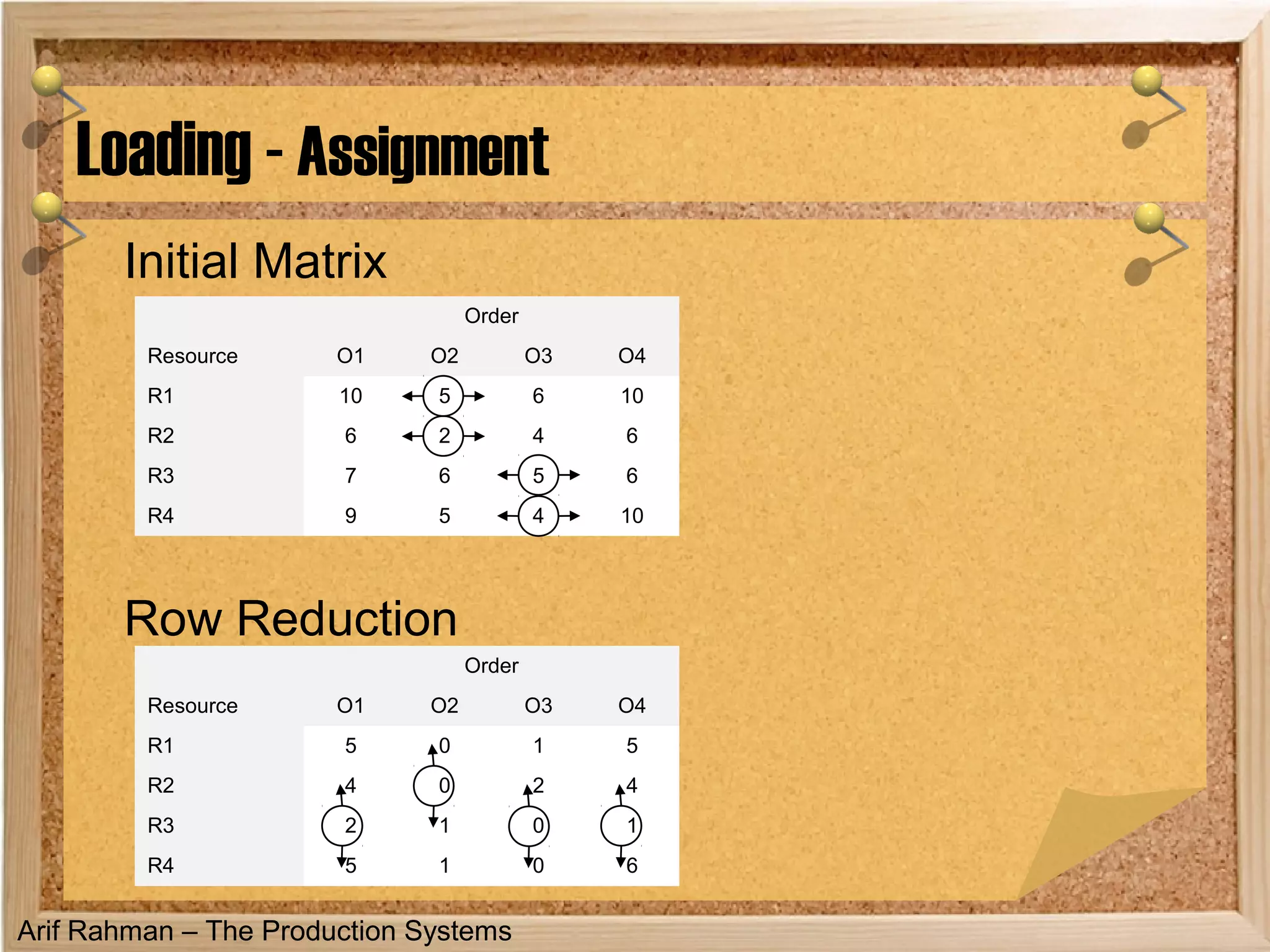

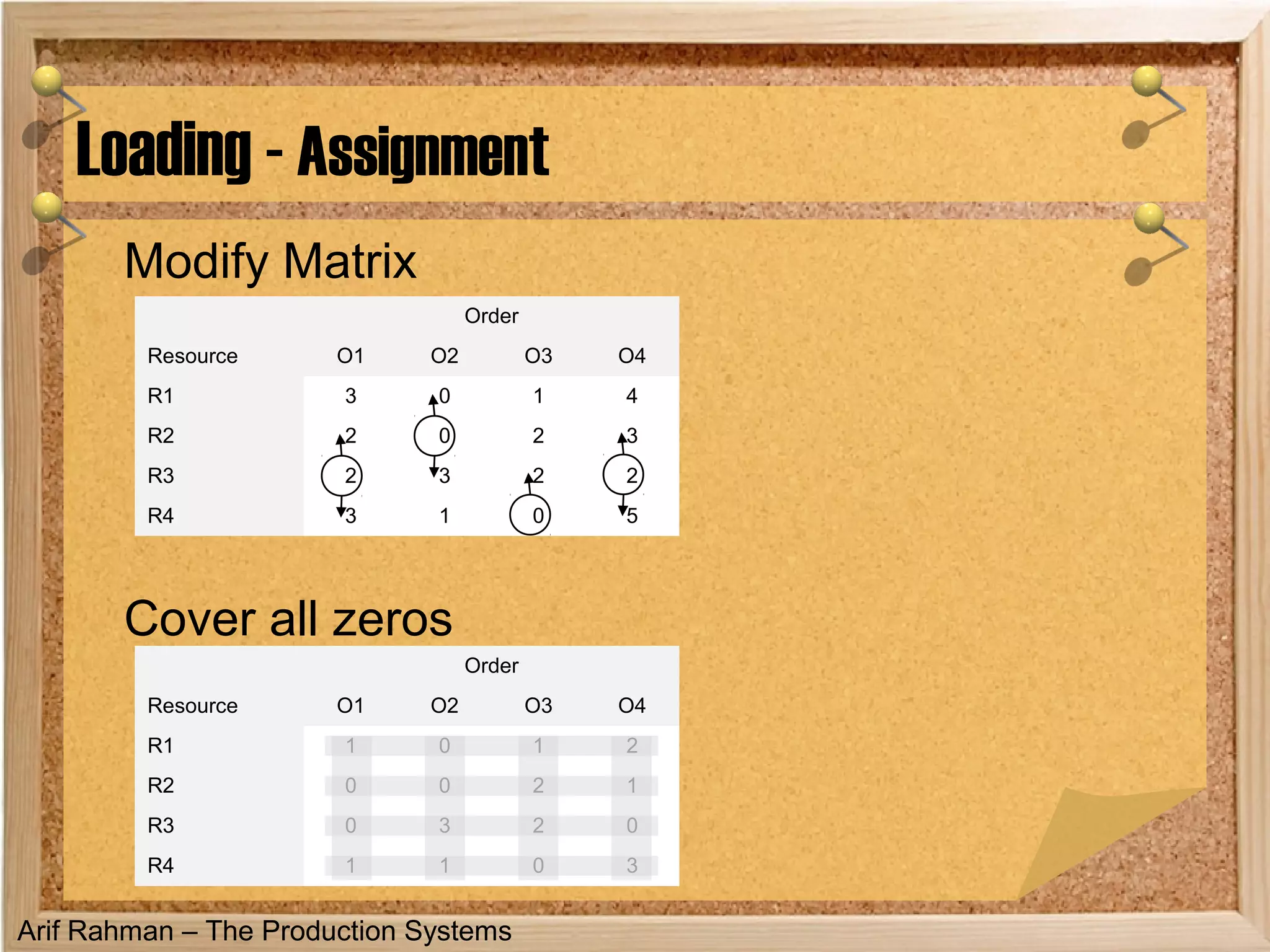

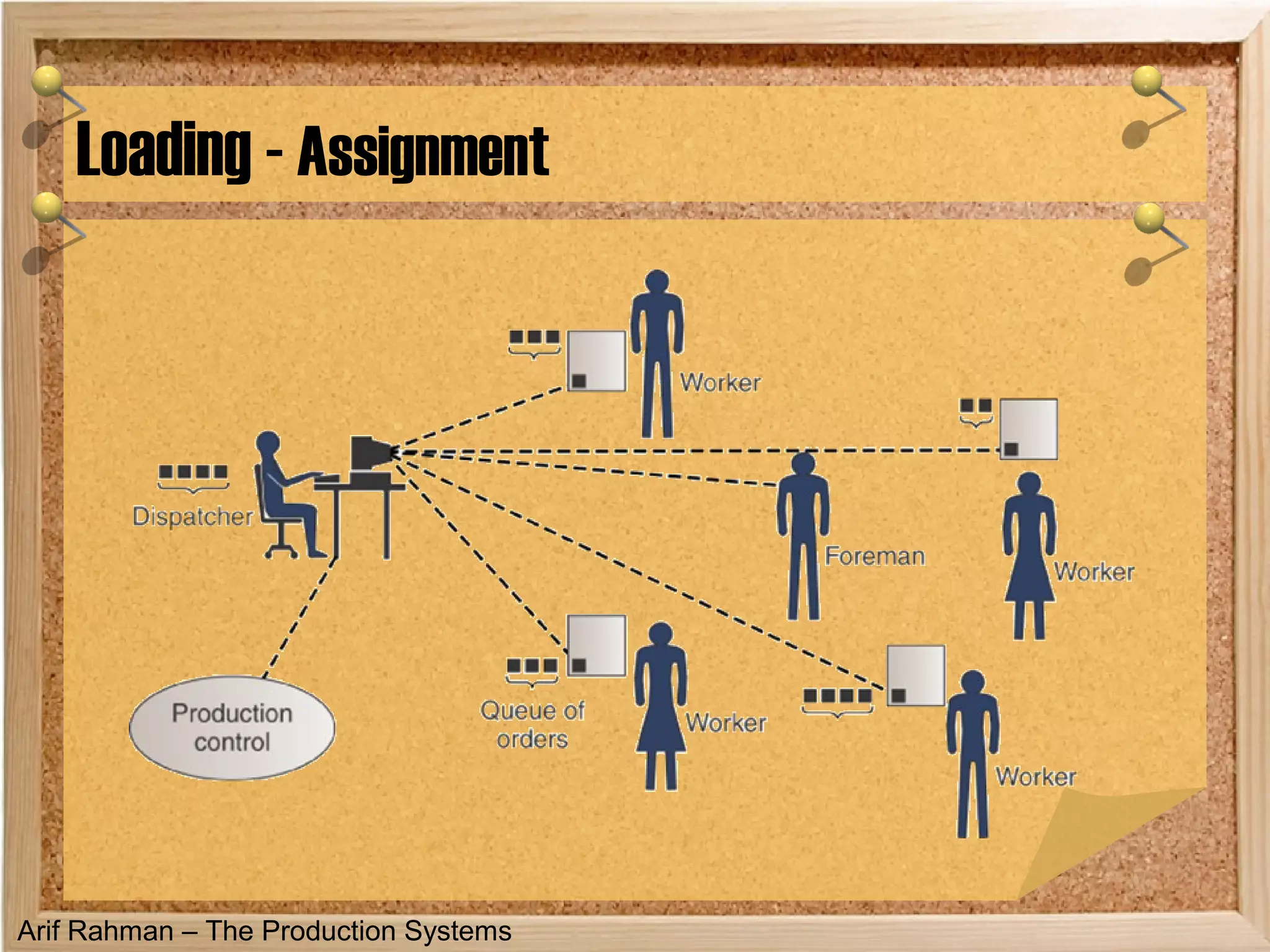

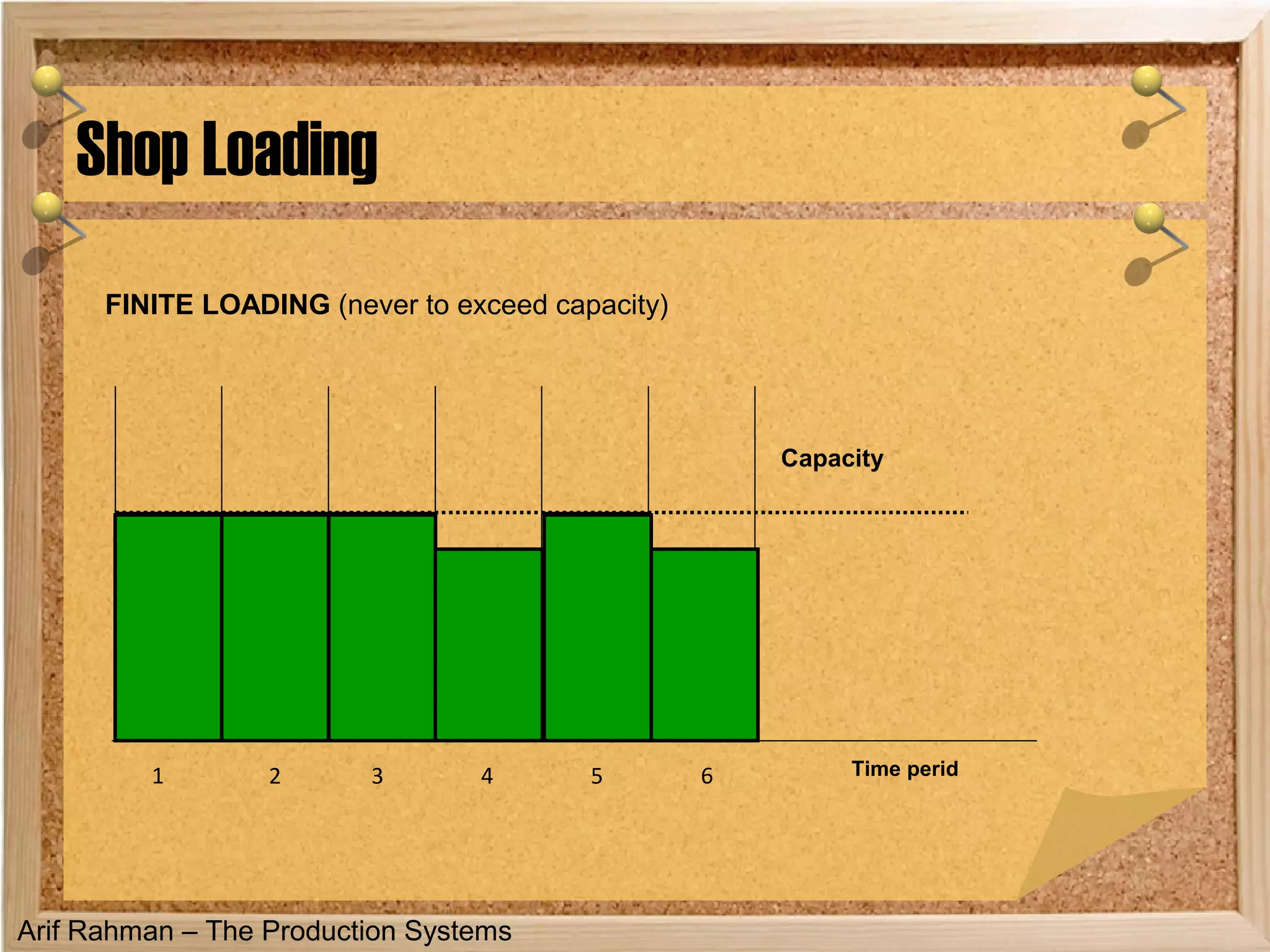

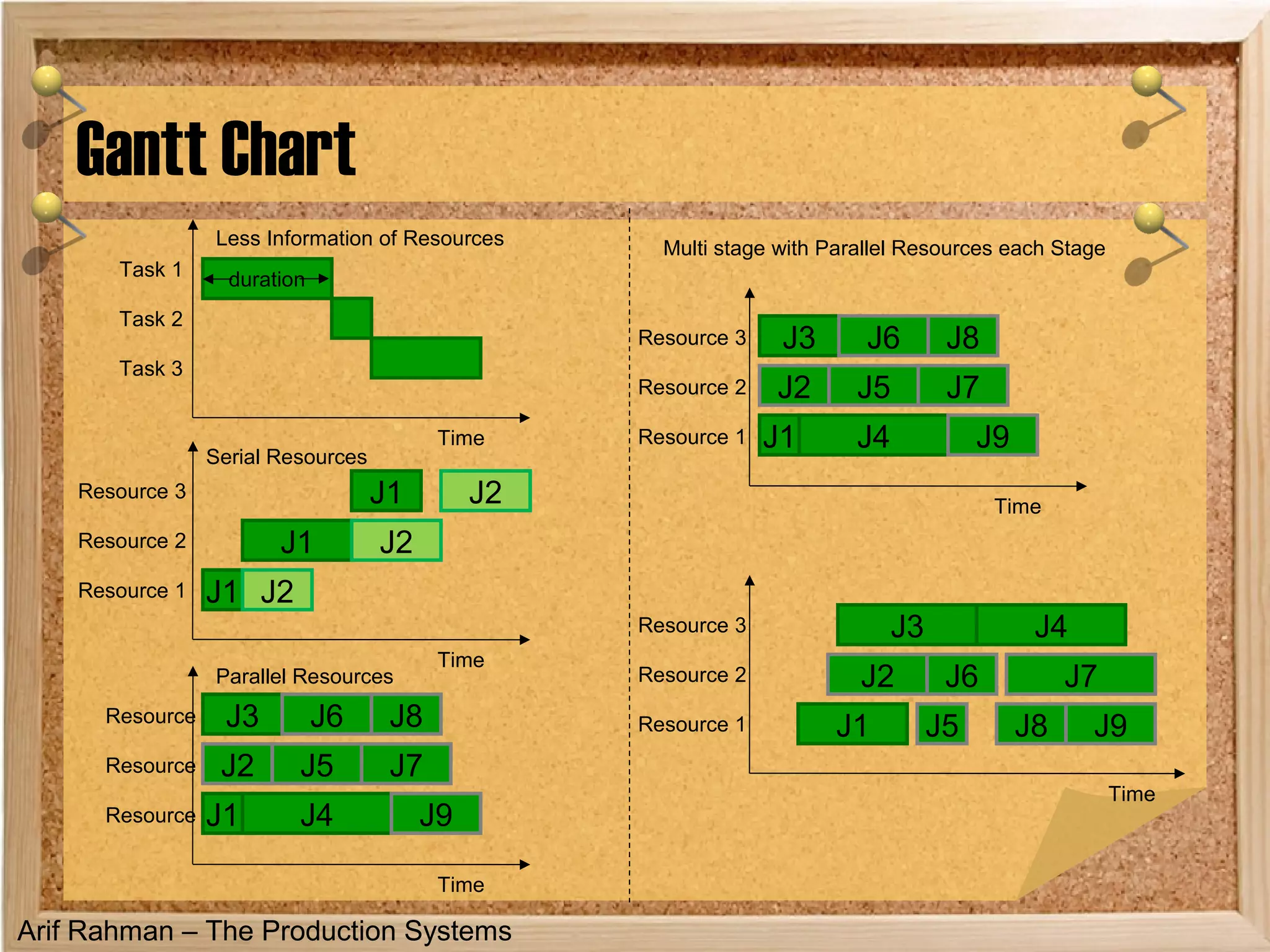

The document discusses shop floor control in manufacturing. It covers key concepts like loading, scheduling, dispatching, and monitoring in shop floor control. Loading involves checking resource availability and assigning work orders. Scheduling develops detailed production schedules using techniques like forward/backward scheduling and priority rules. Dispatching implements schedules based on real-time shop floor status. Monitoring tracks work progress, throughput, quality and provides performance feedback using tools like dashboards and Gantt charts. Overall, the document provides an overview of the main functions and processes involved in shop floor control systems that plan and control work flow on the manufacturing plant floor.