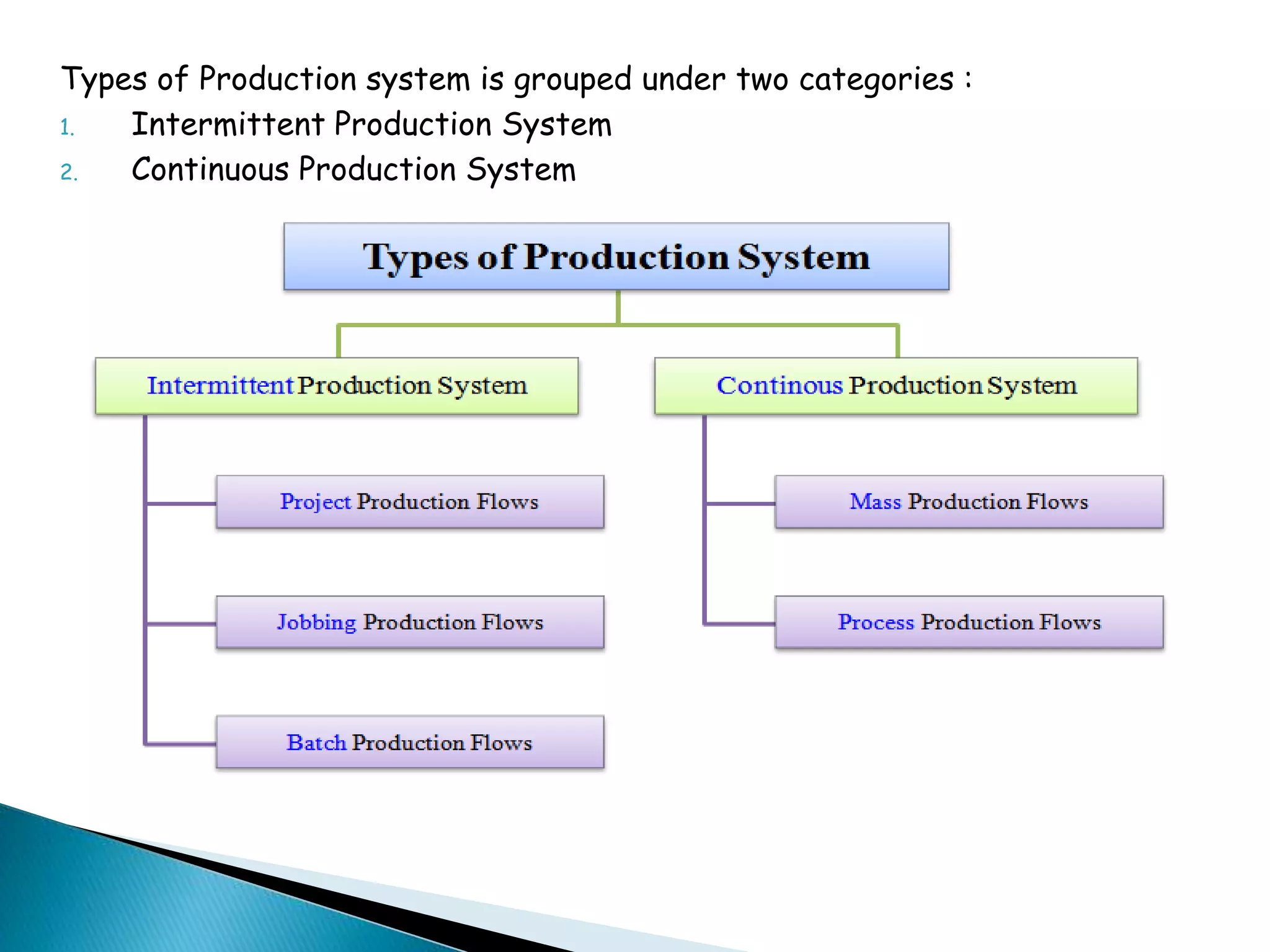

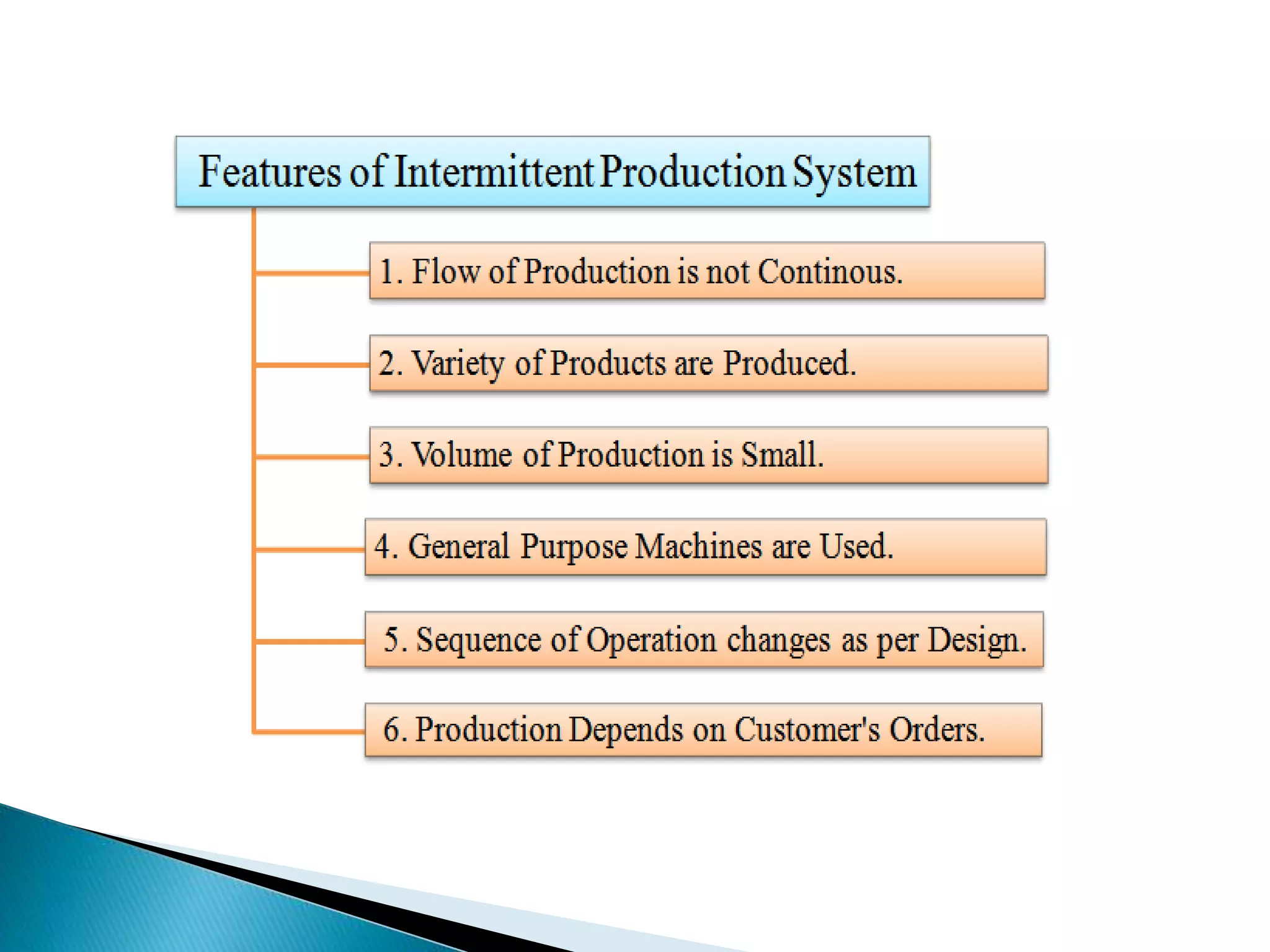

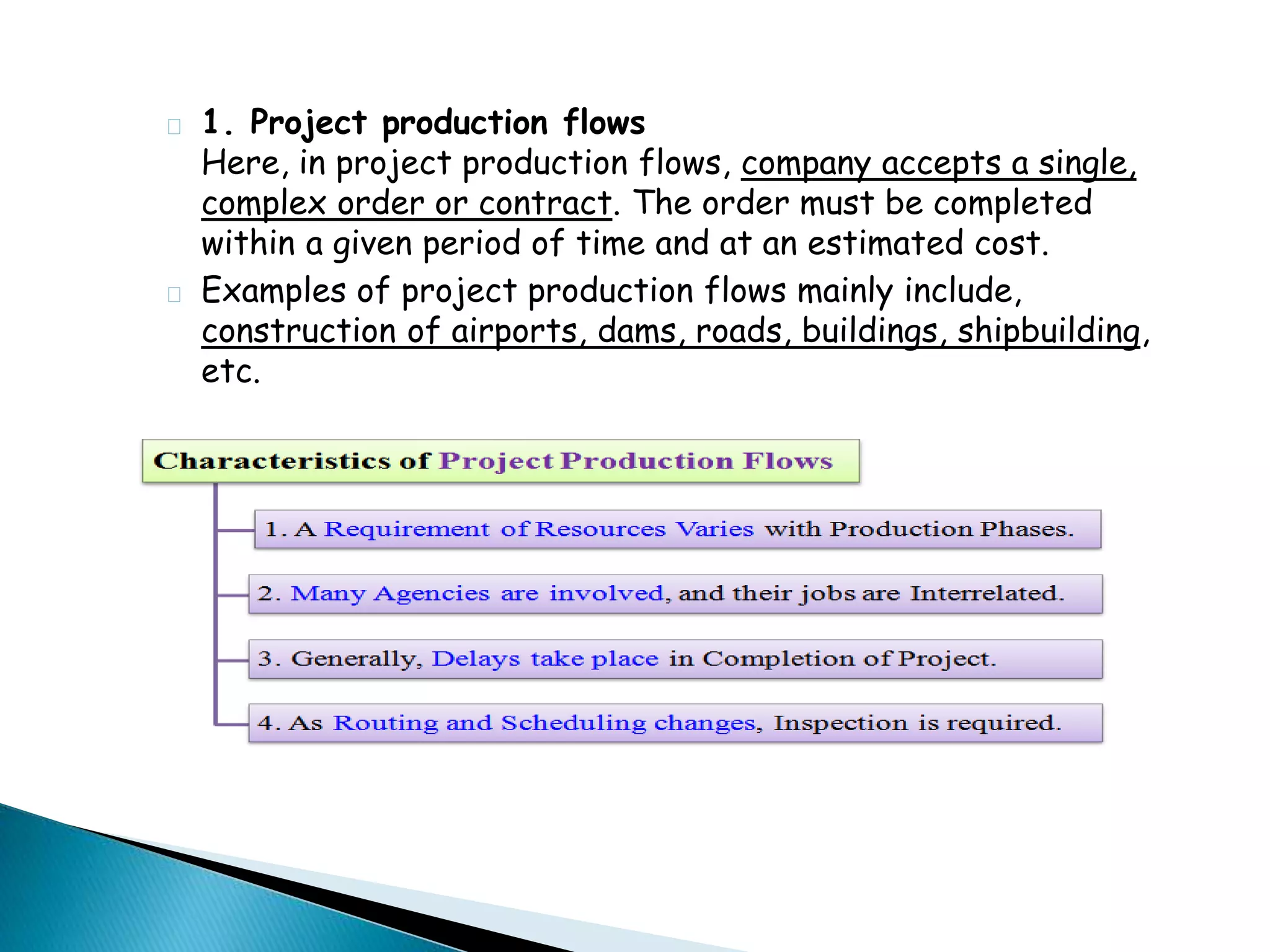

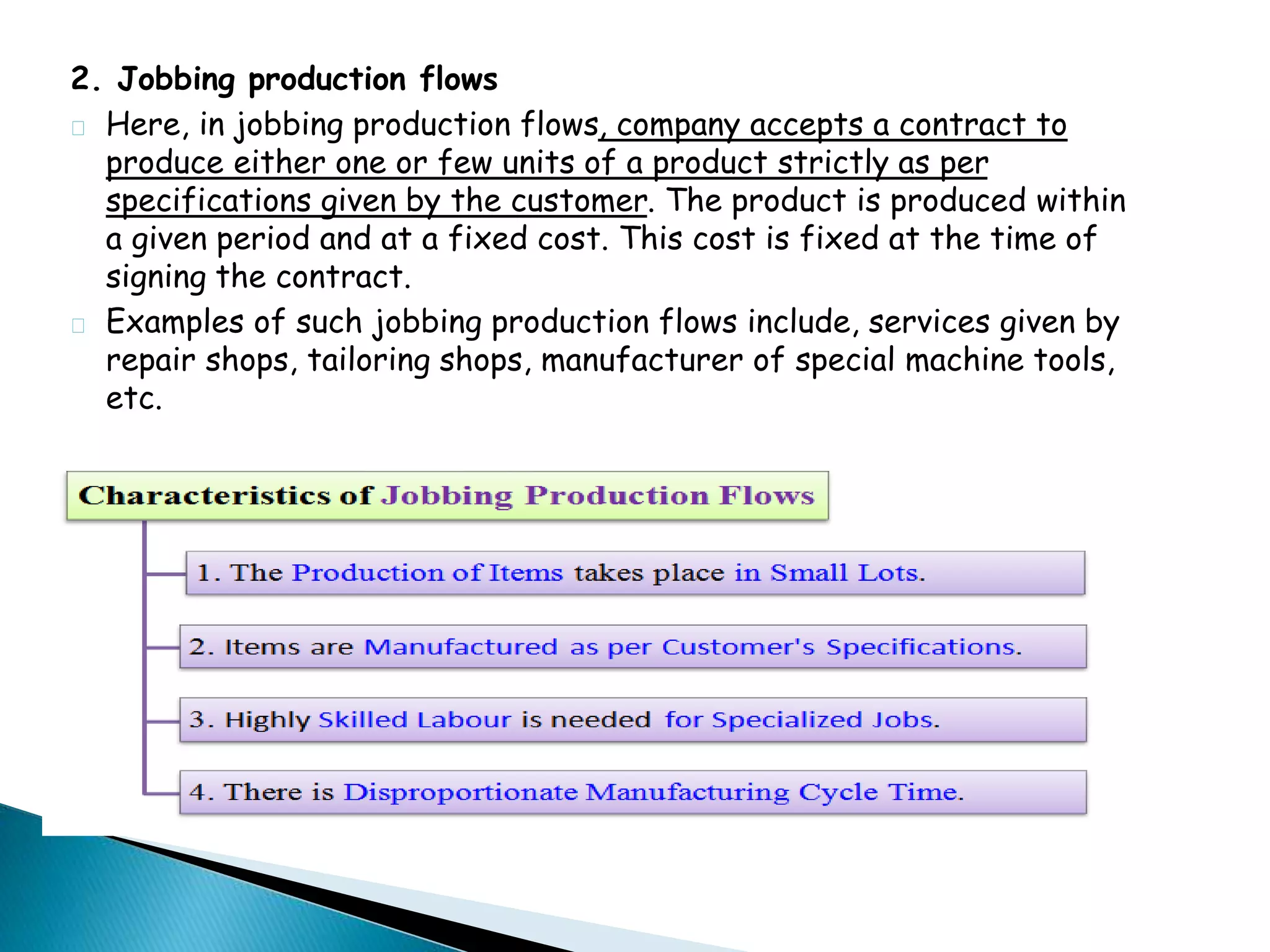

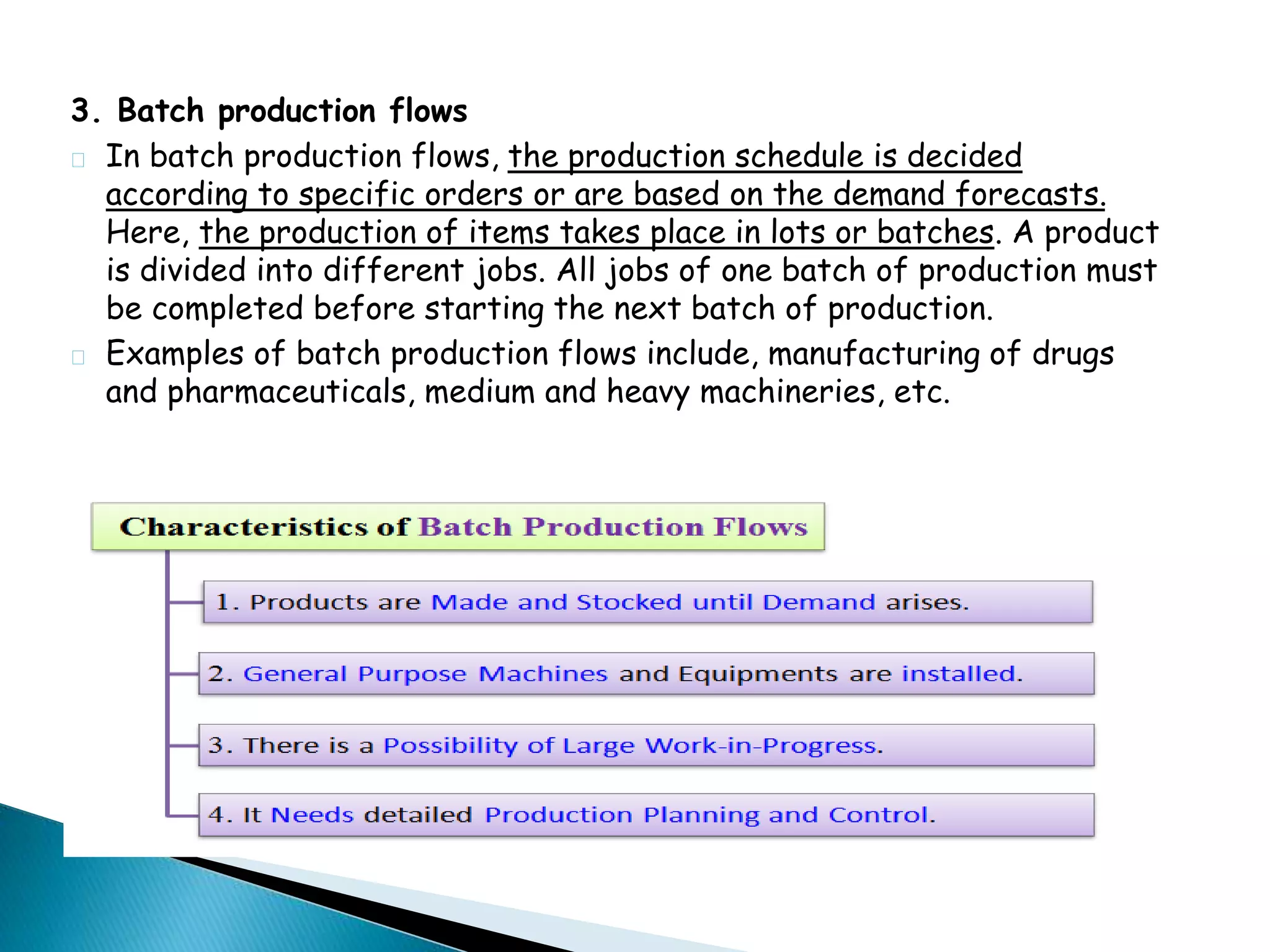

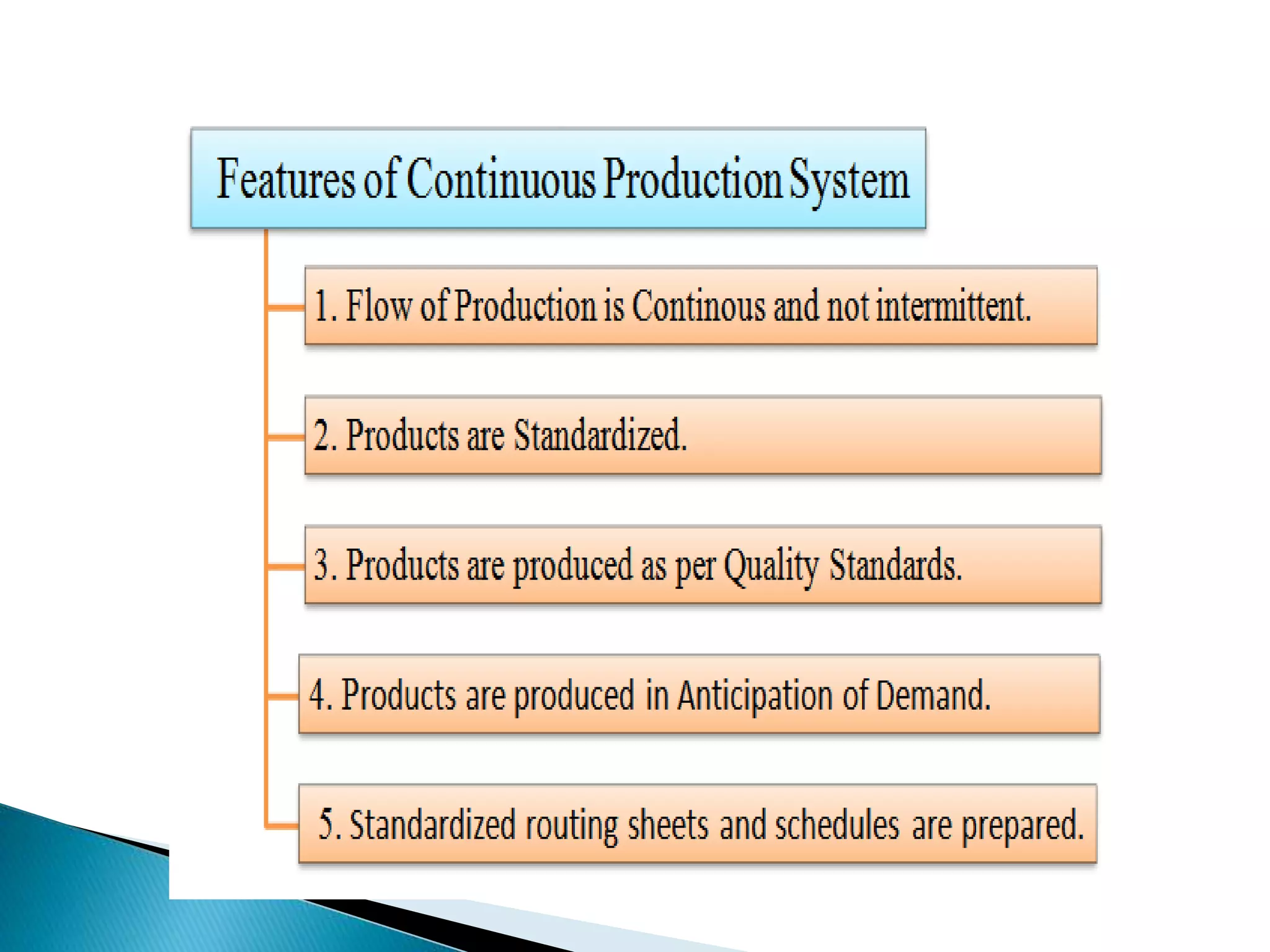

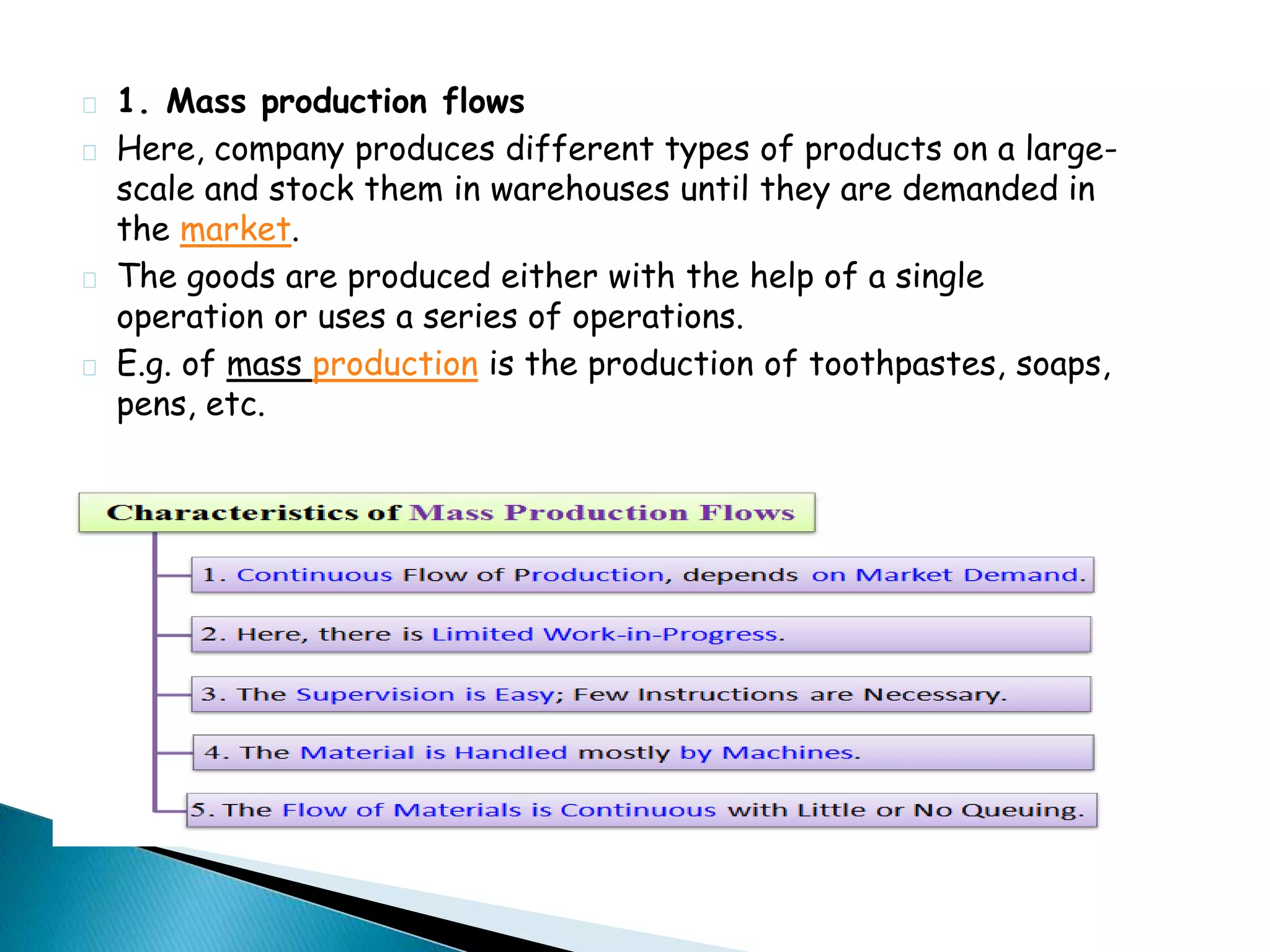

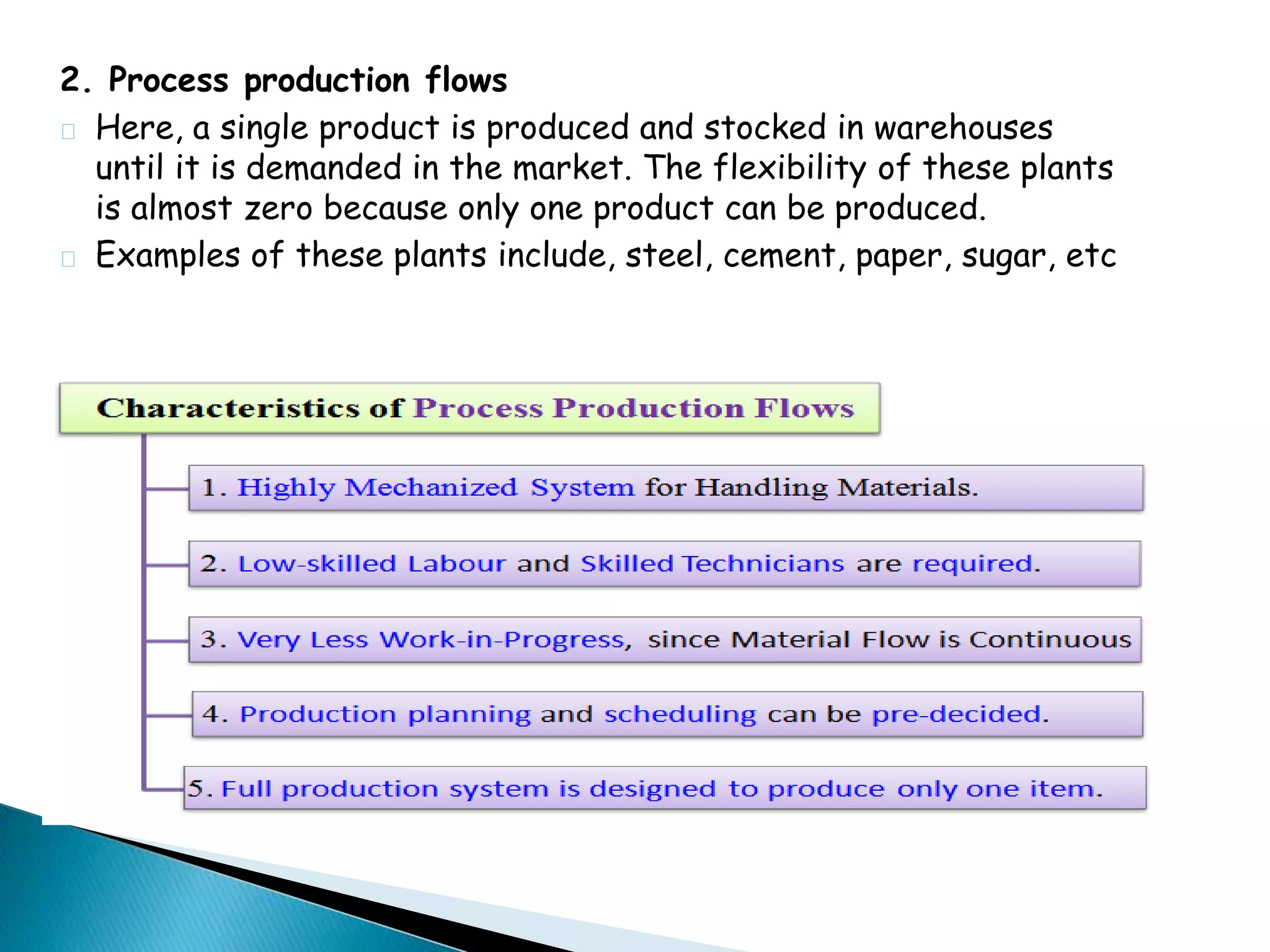

The document discusses two types of production systems: intermittent and continuous. Intermittent production occurs on a small scale based on customer orders and is flexible. Continuous production occurs on a large scale based on demand forecasts and has standardized processes. Within each system there are different types of production flows, such as project, jobbing, and batch production for intermittent systems, and mass and process production for continuous systems. Examples are provided for each type of production flow.