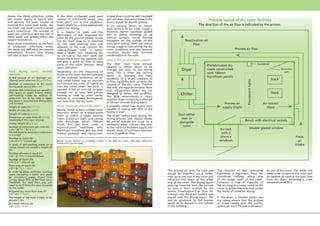

The document provides guidelines for designing and operating a dry room for seed banking, emphasizing the importance of reducing seed moisture to prolong storage life. It outlines necessary equipment, construction materials, and operational procedures to maintain low humidity and cool temperatures. Detailed calculations for space requirements and air flow management are also included, highlighting the significance of proper ventilation and moisture control for effective seed conservation.