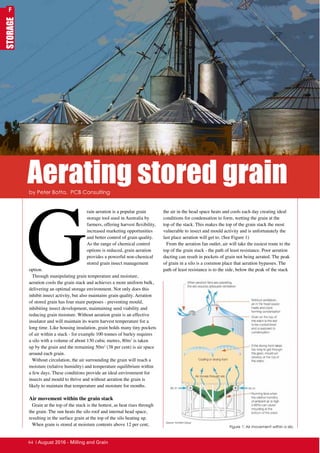

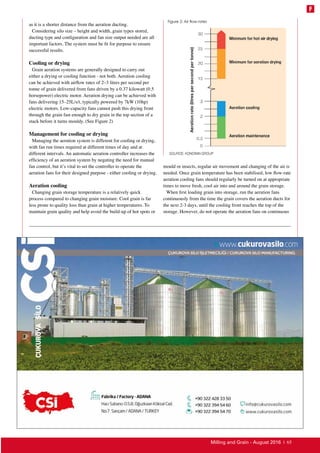

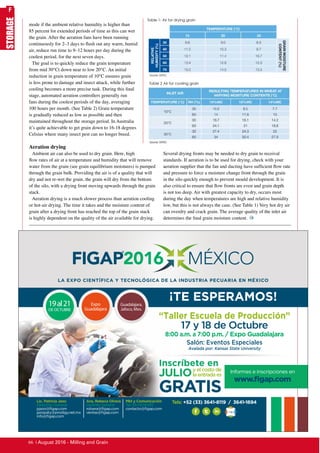

Grain aeration is an essential storage tool for Australian farmers that enhances grain quality by managing temperature and moisture, thereby inhibiting insect activity and preventing mould. Effective aeration systems must be properly designed for cooling or drying, with specific airflow rates and management strategies to ensure optimal grain storage conditions. The process requires continuous monitoring and adjustment to maintain grain temperature and moisture levels while preventing condensation that can lead to spoilage.