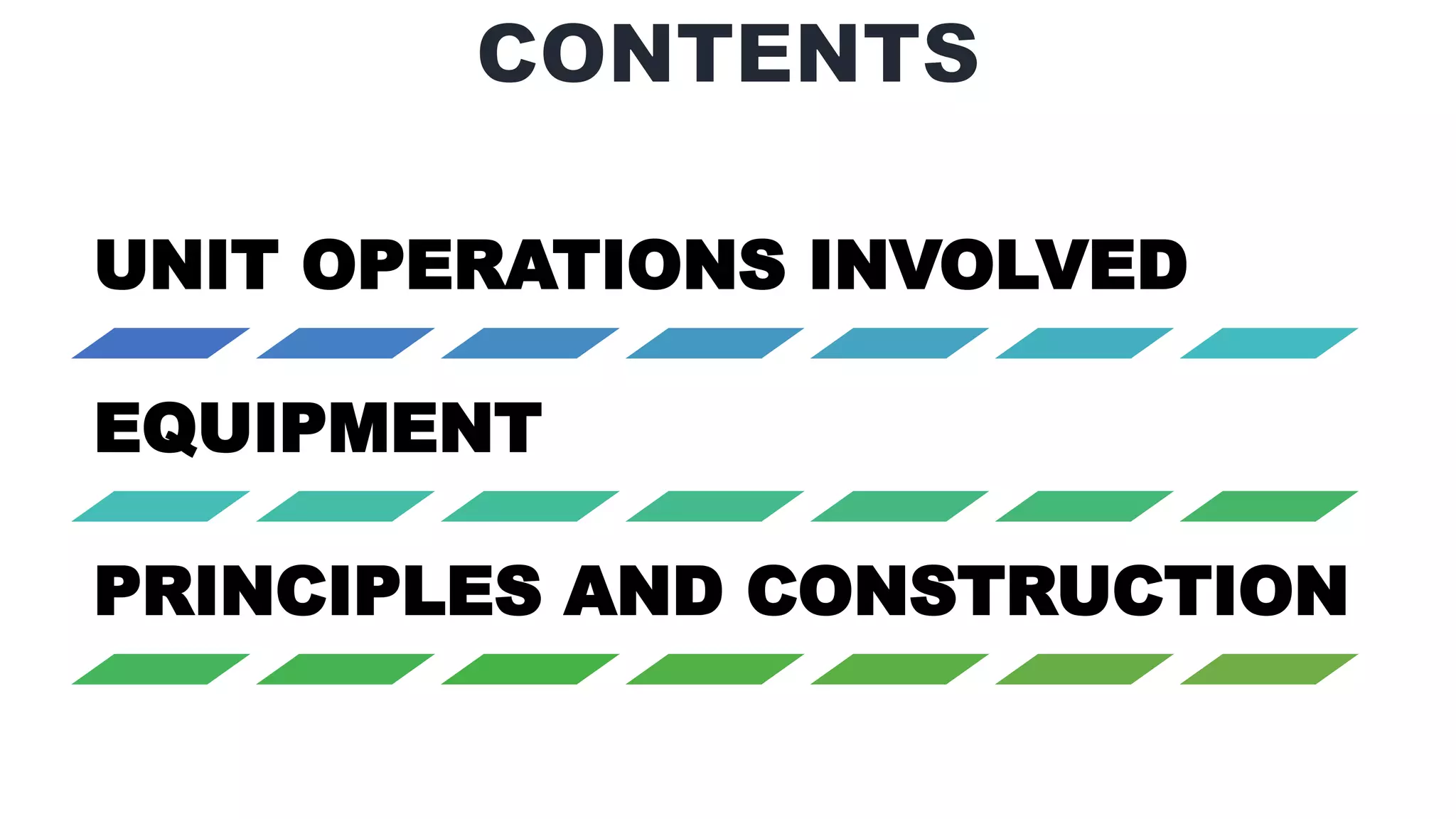

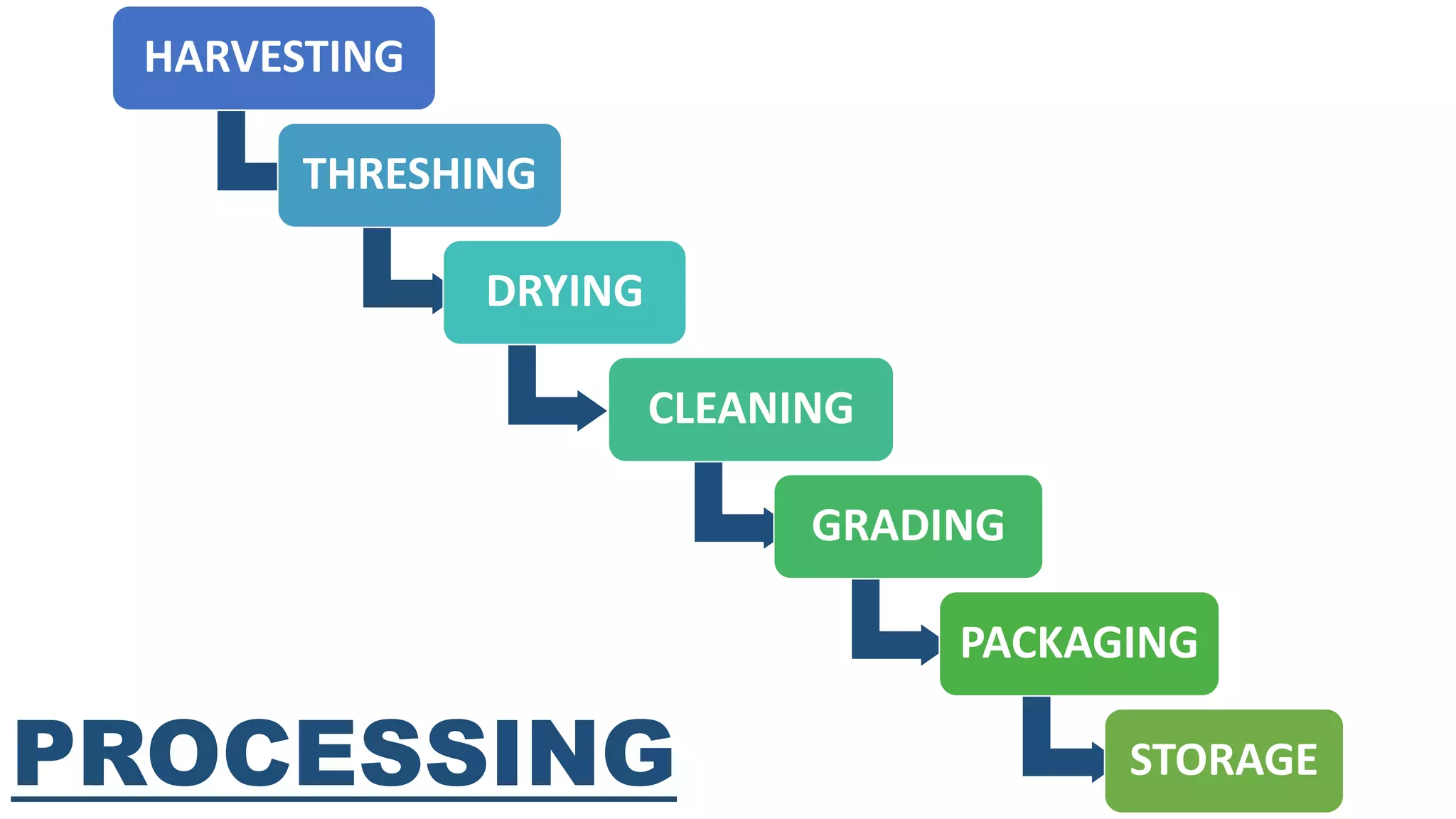

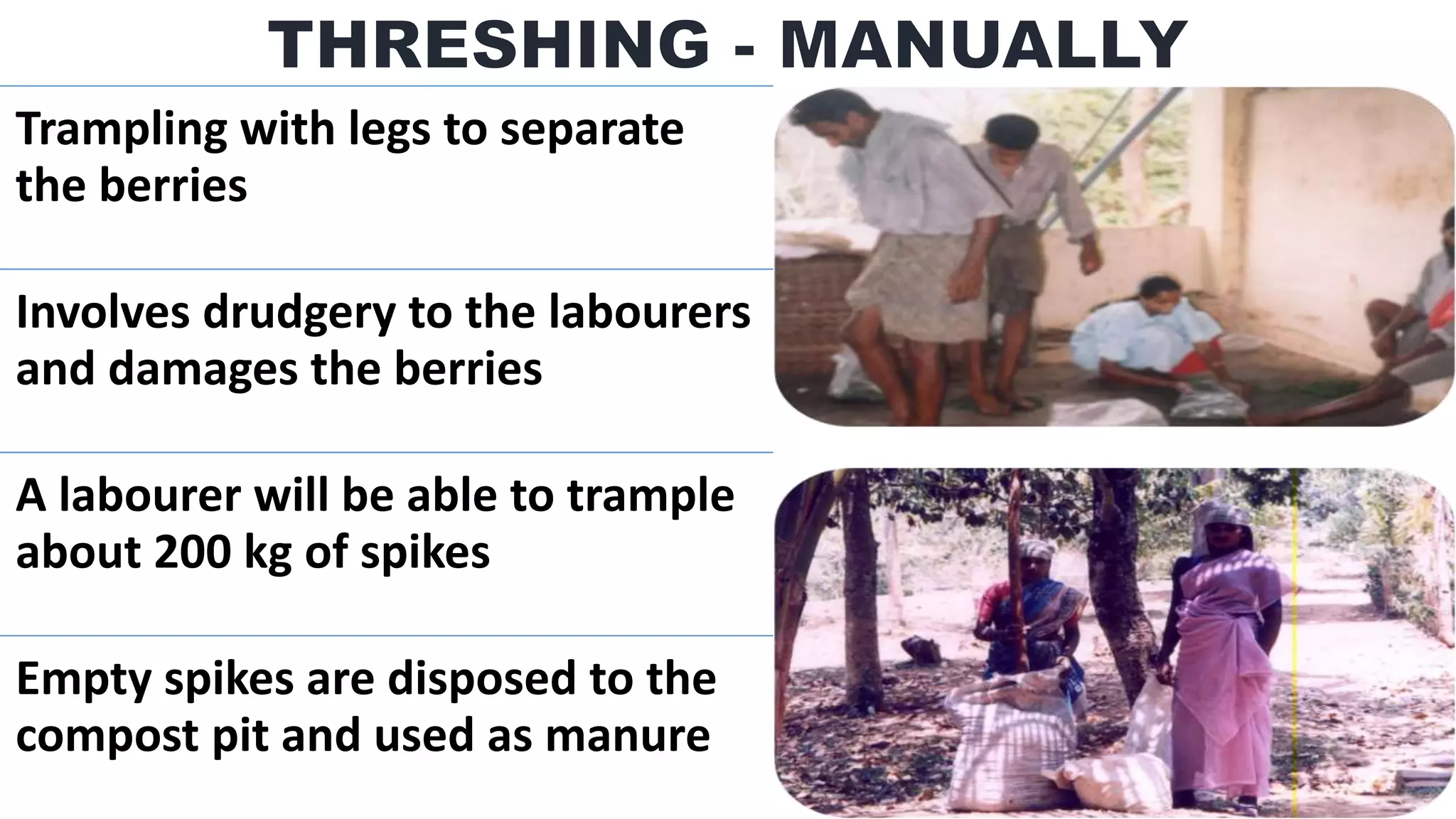

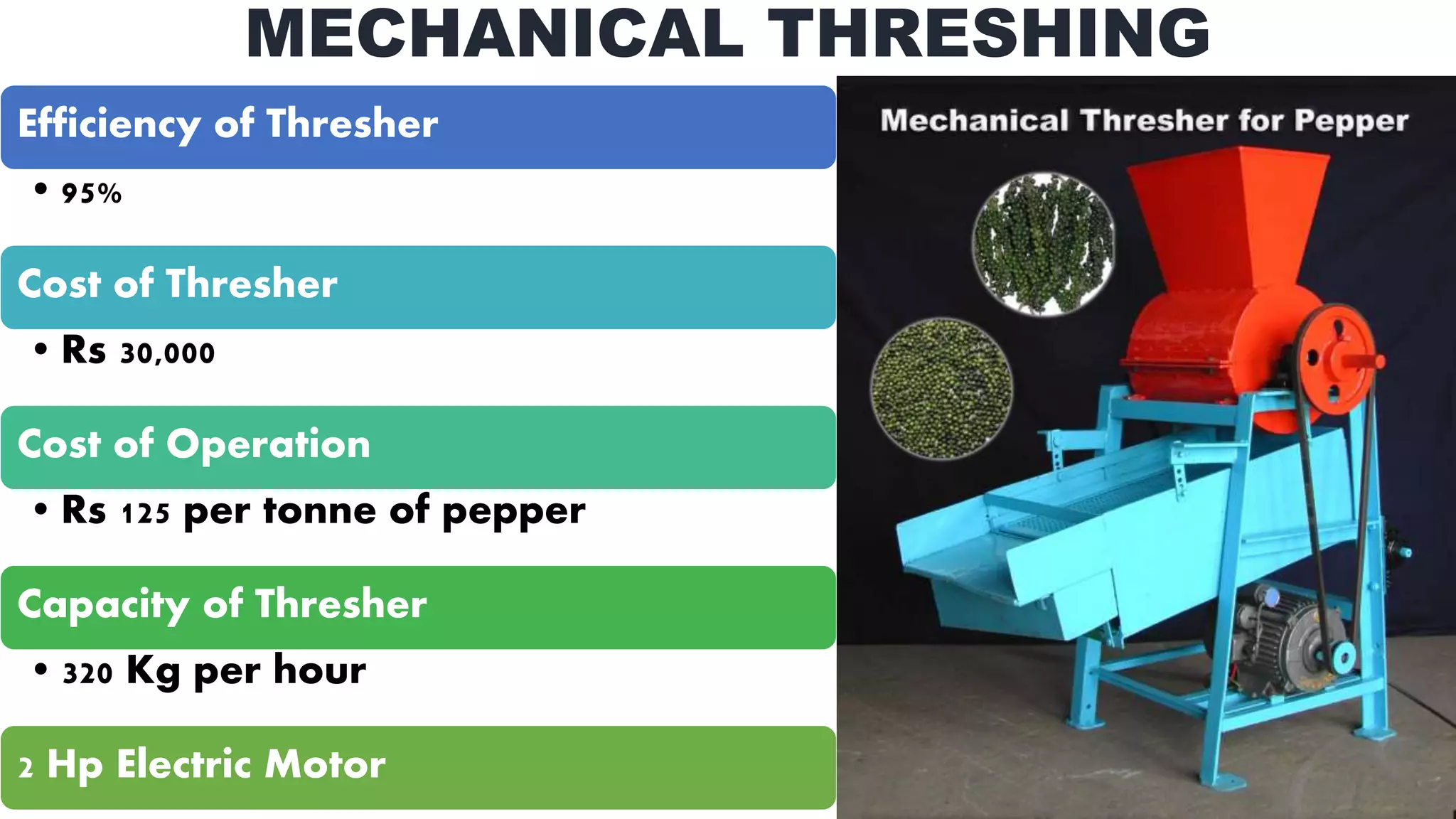

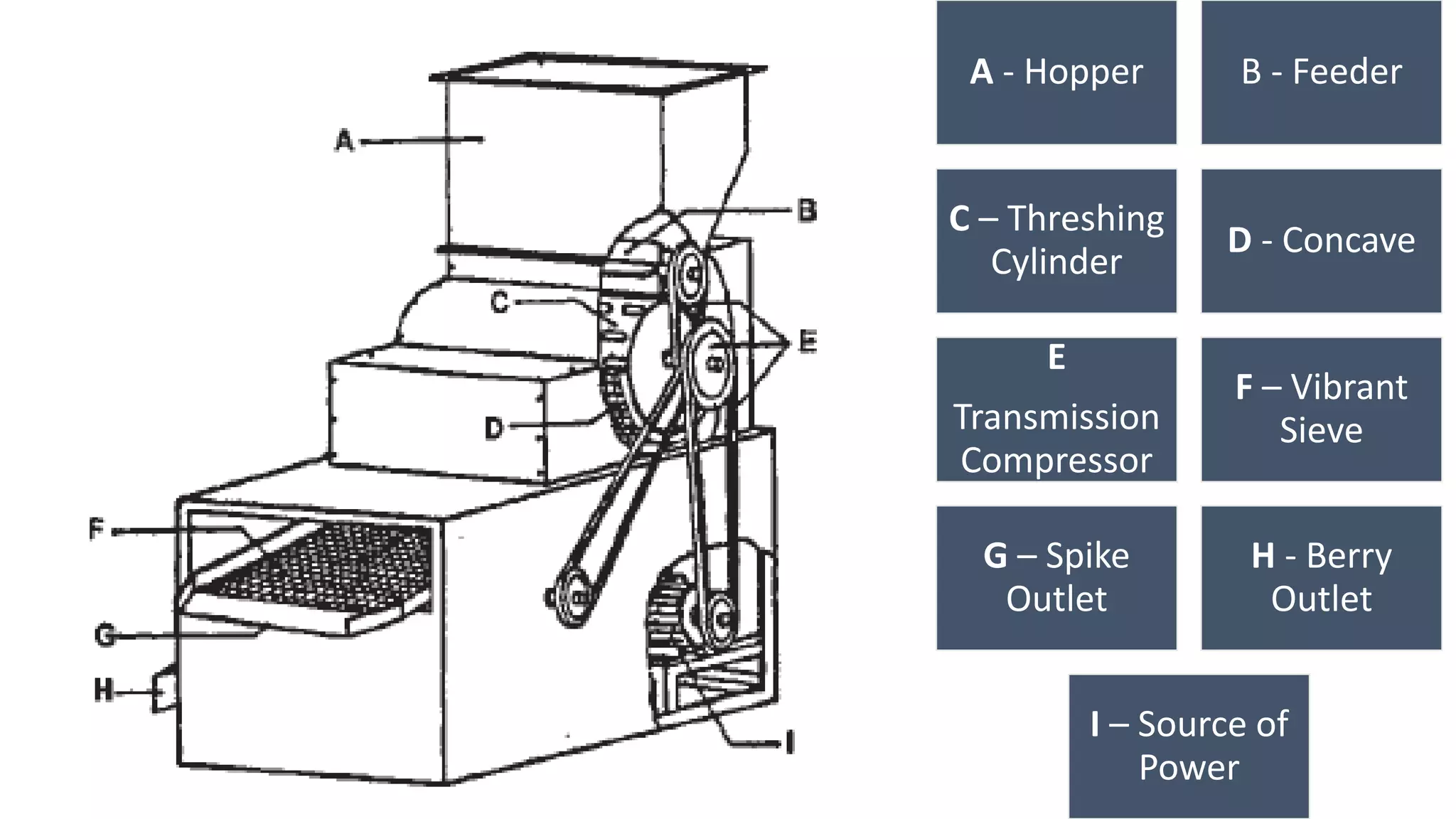

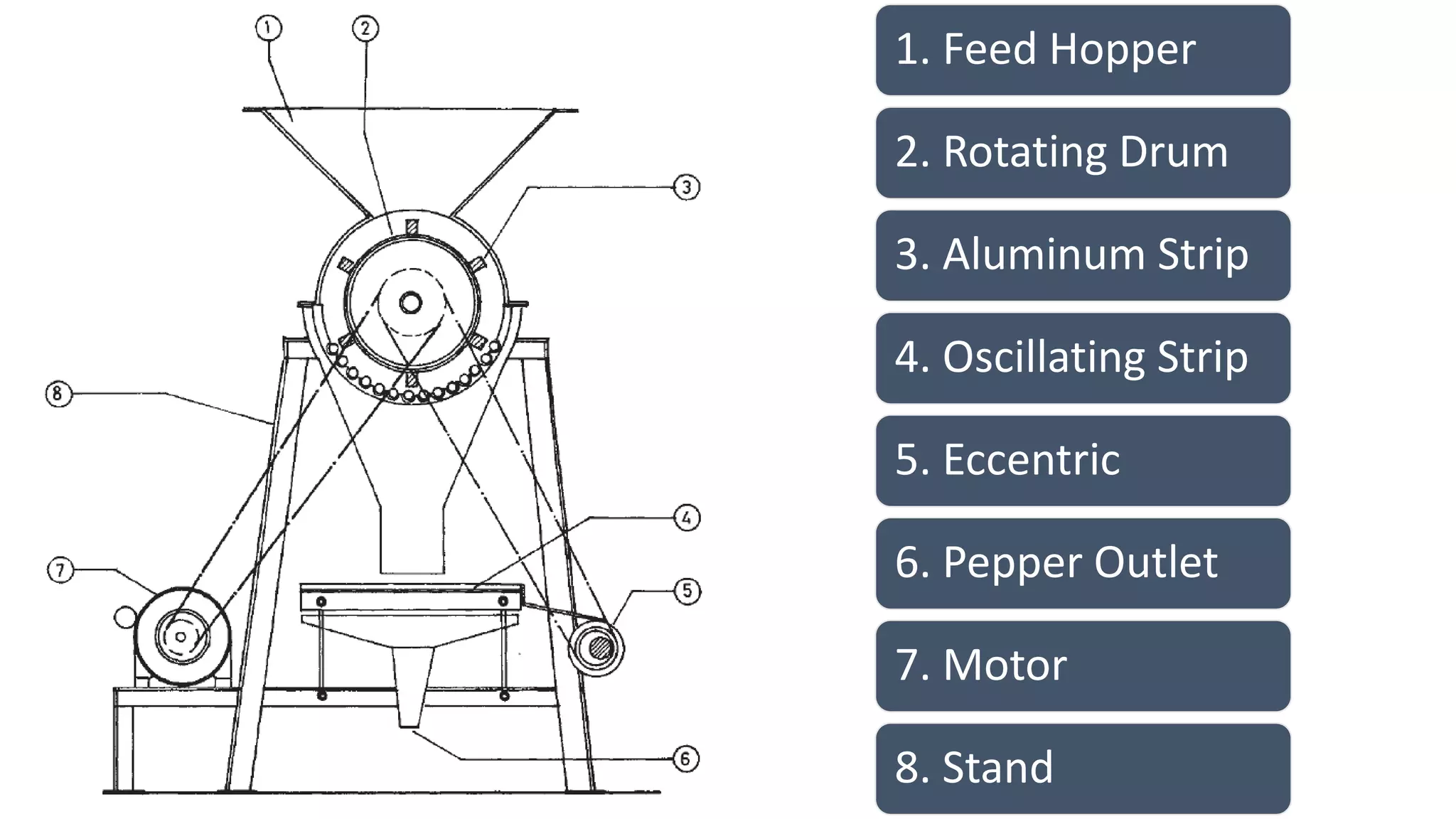

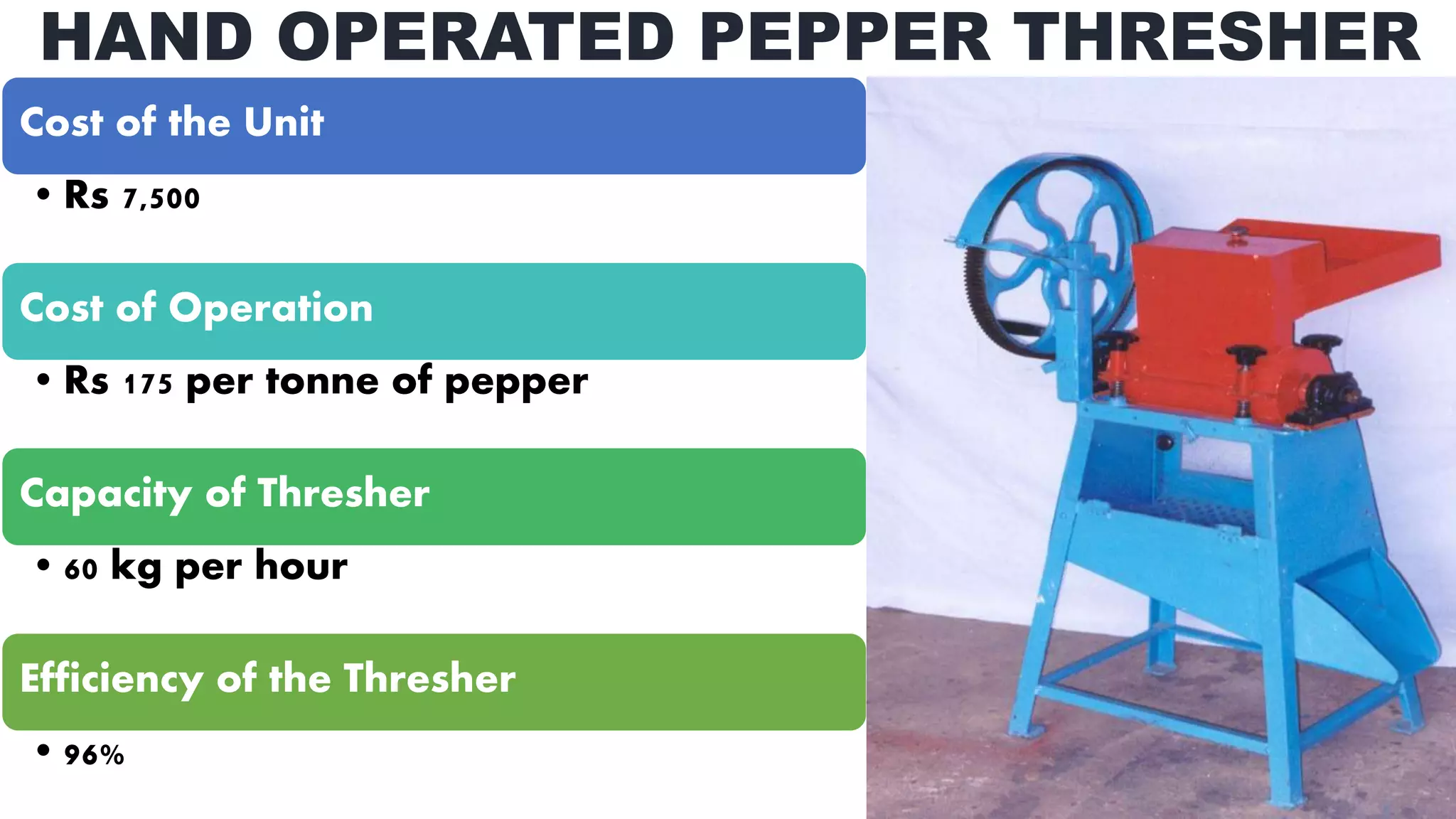

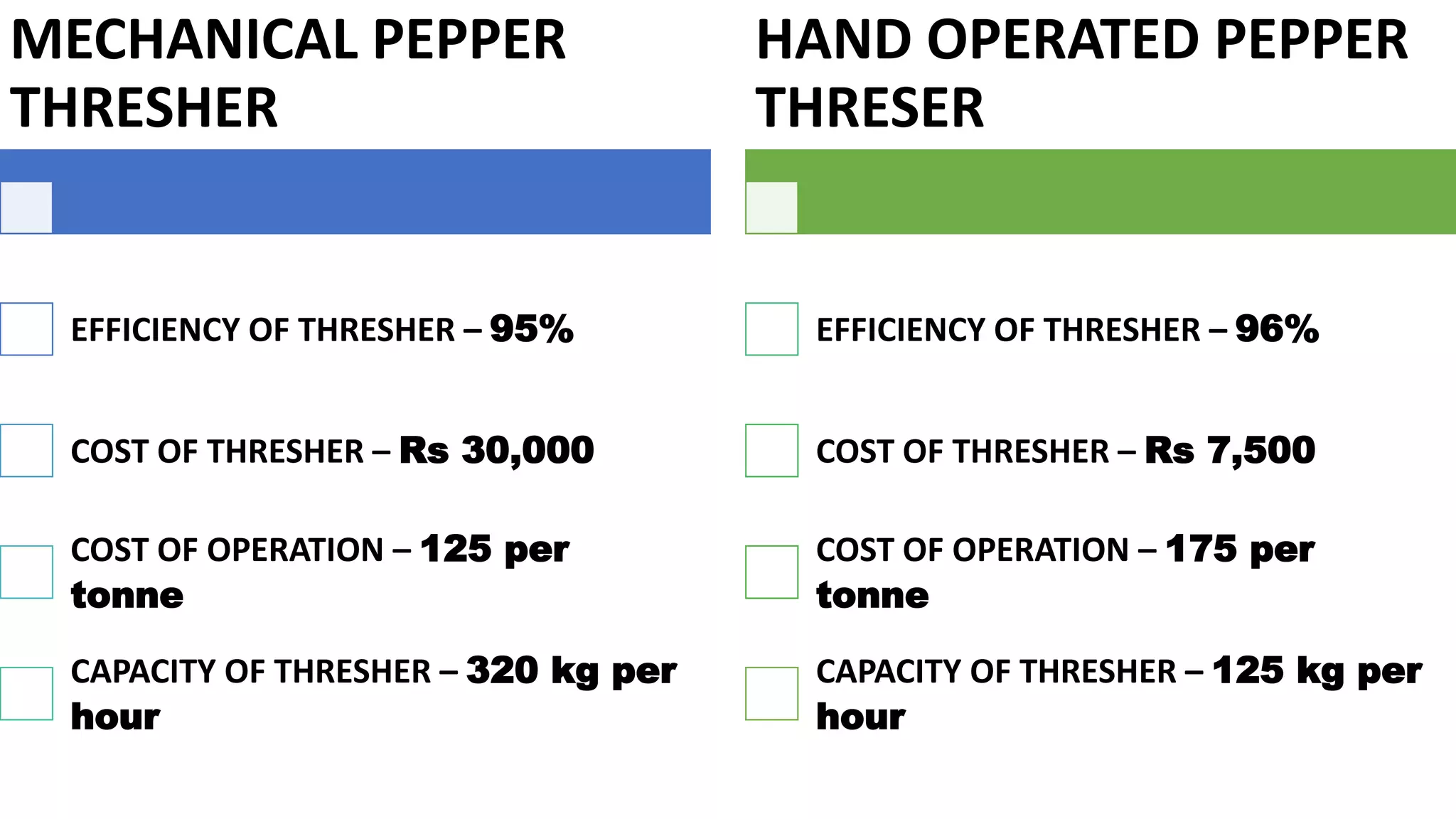

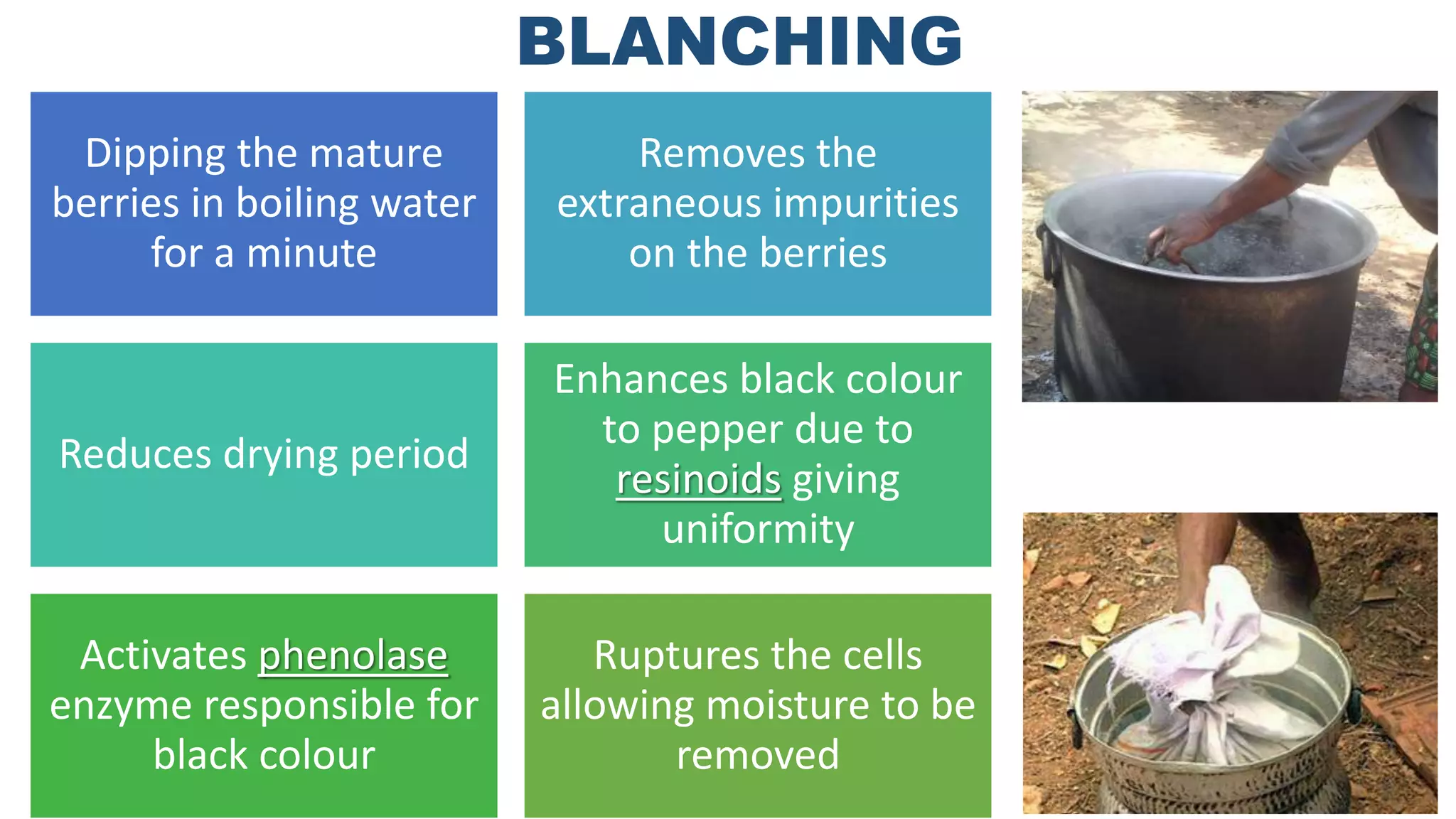

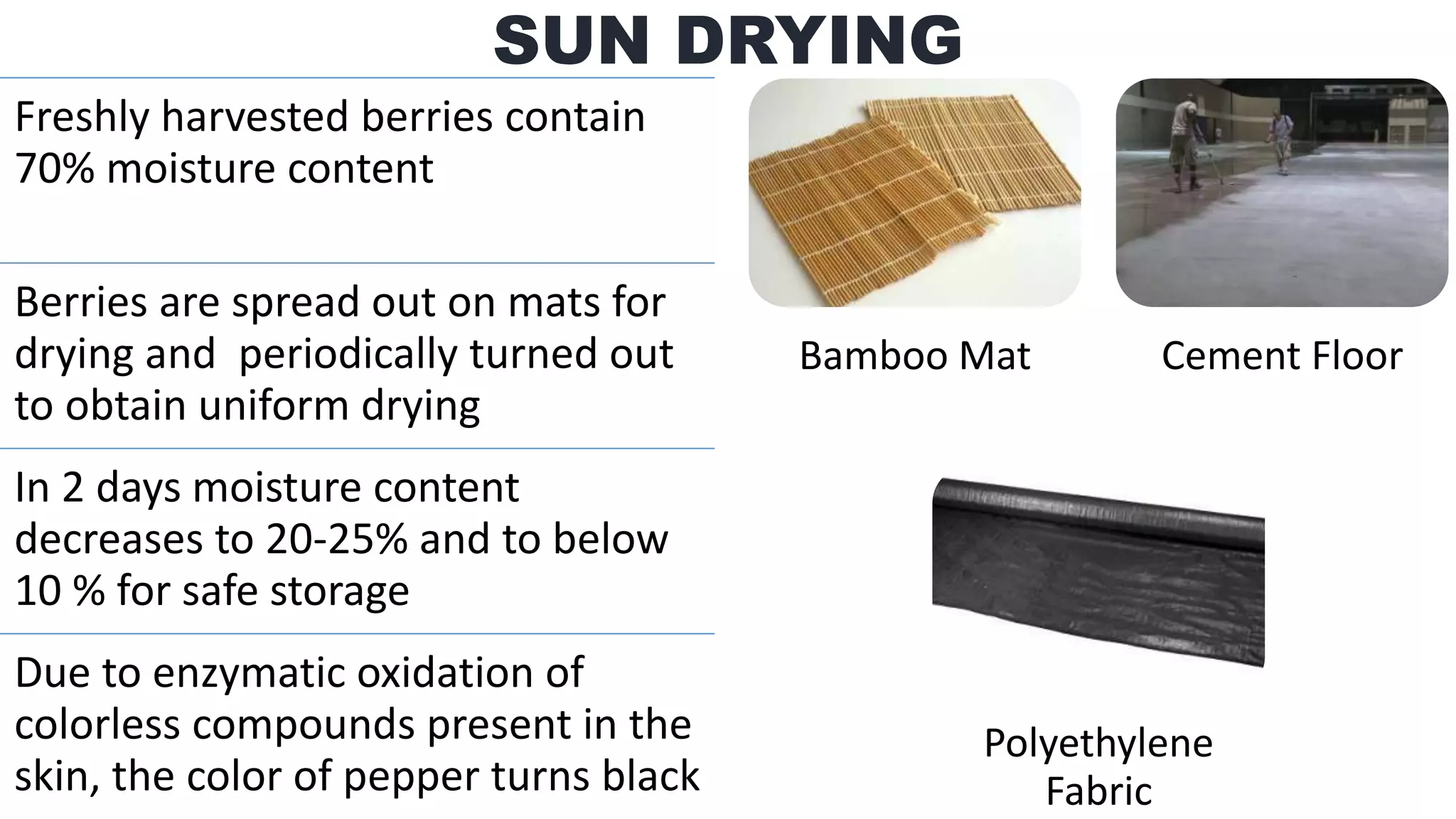

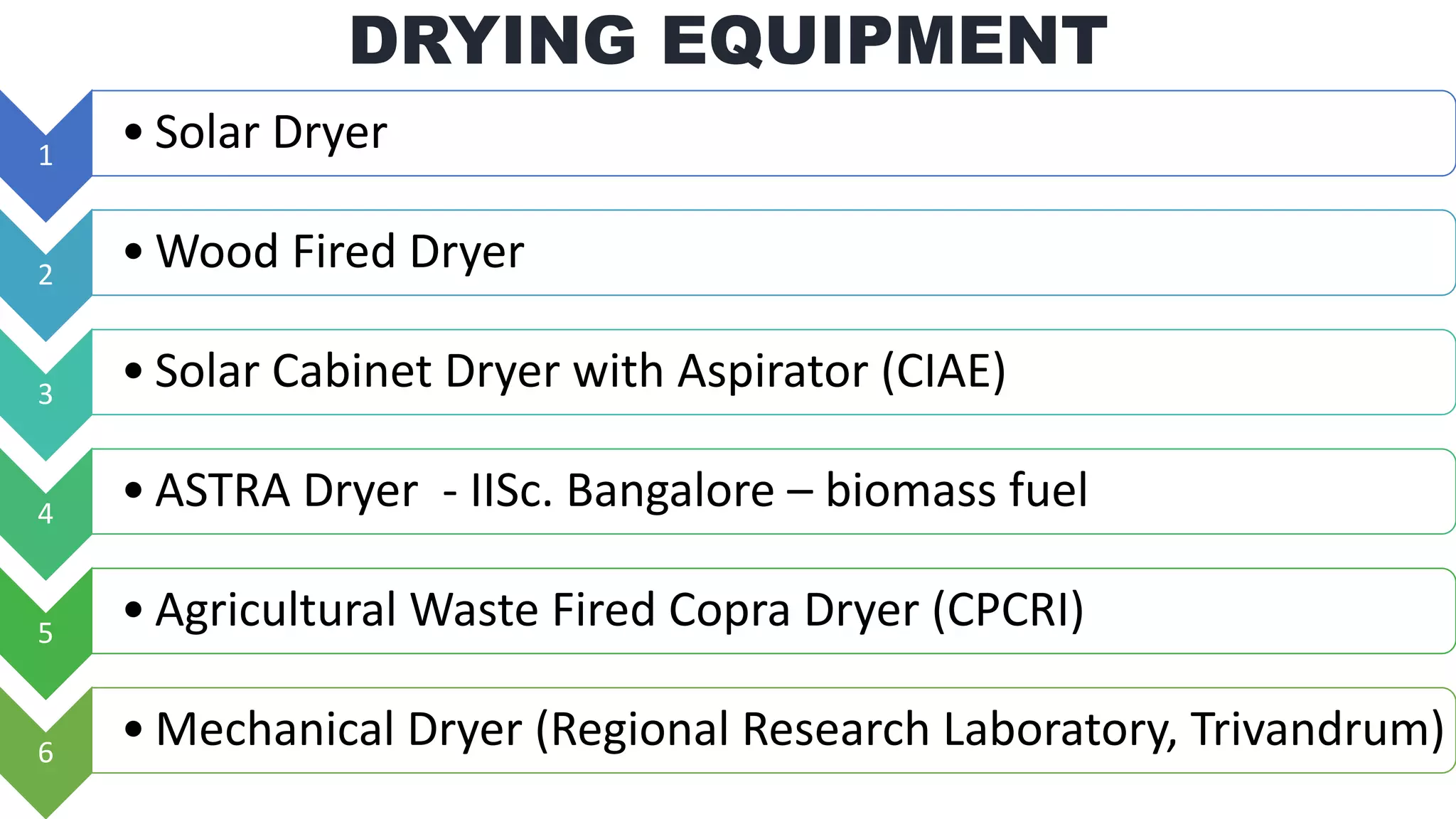

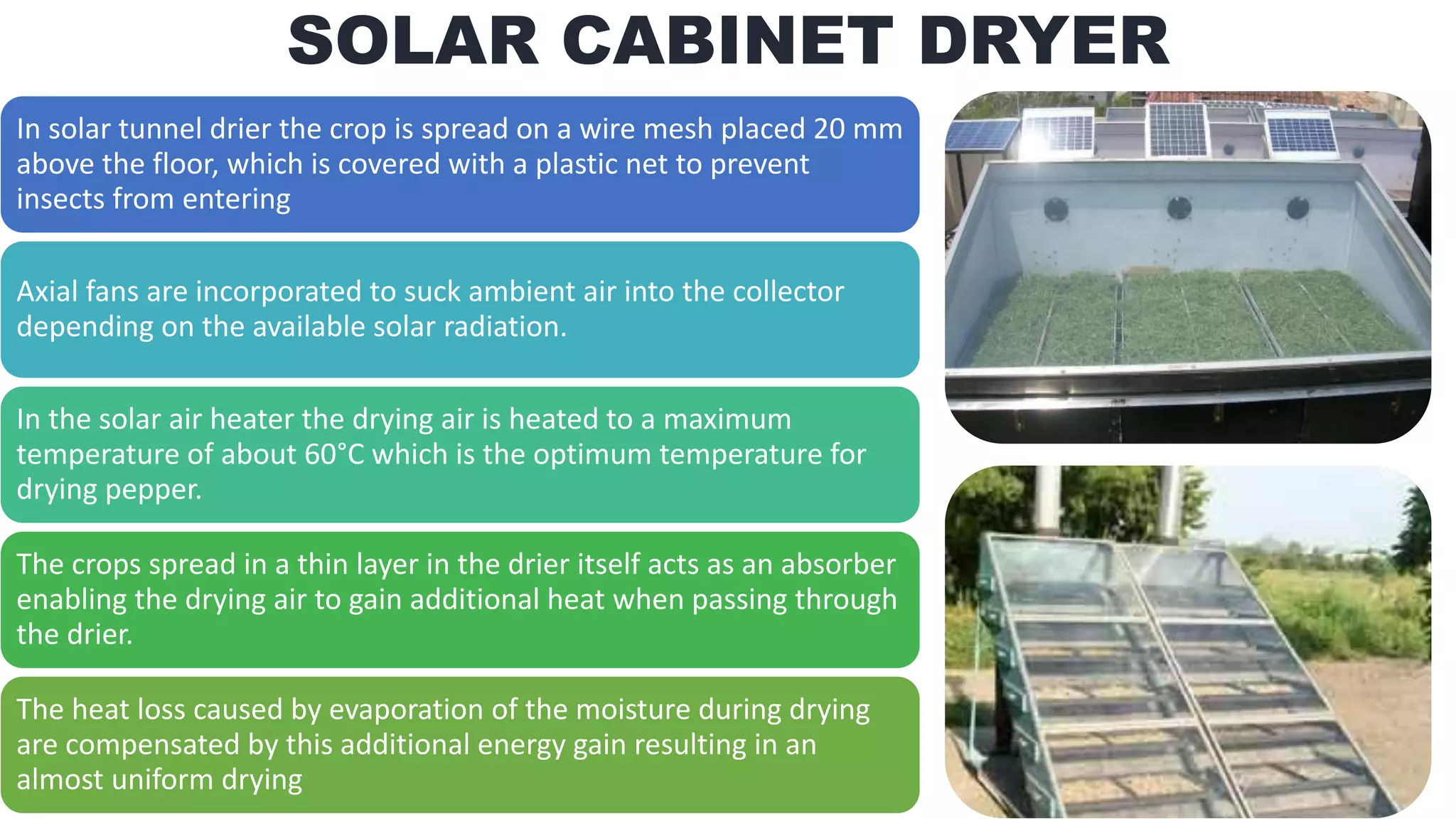

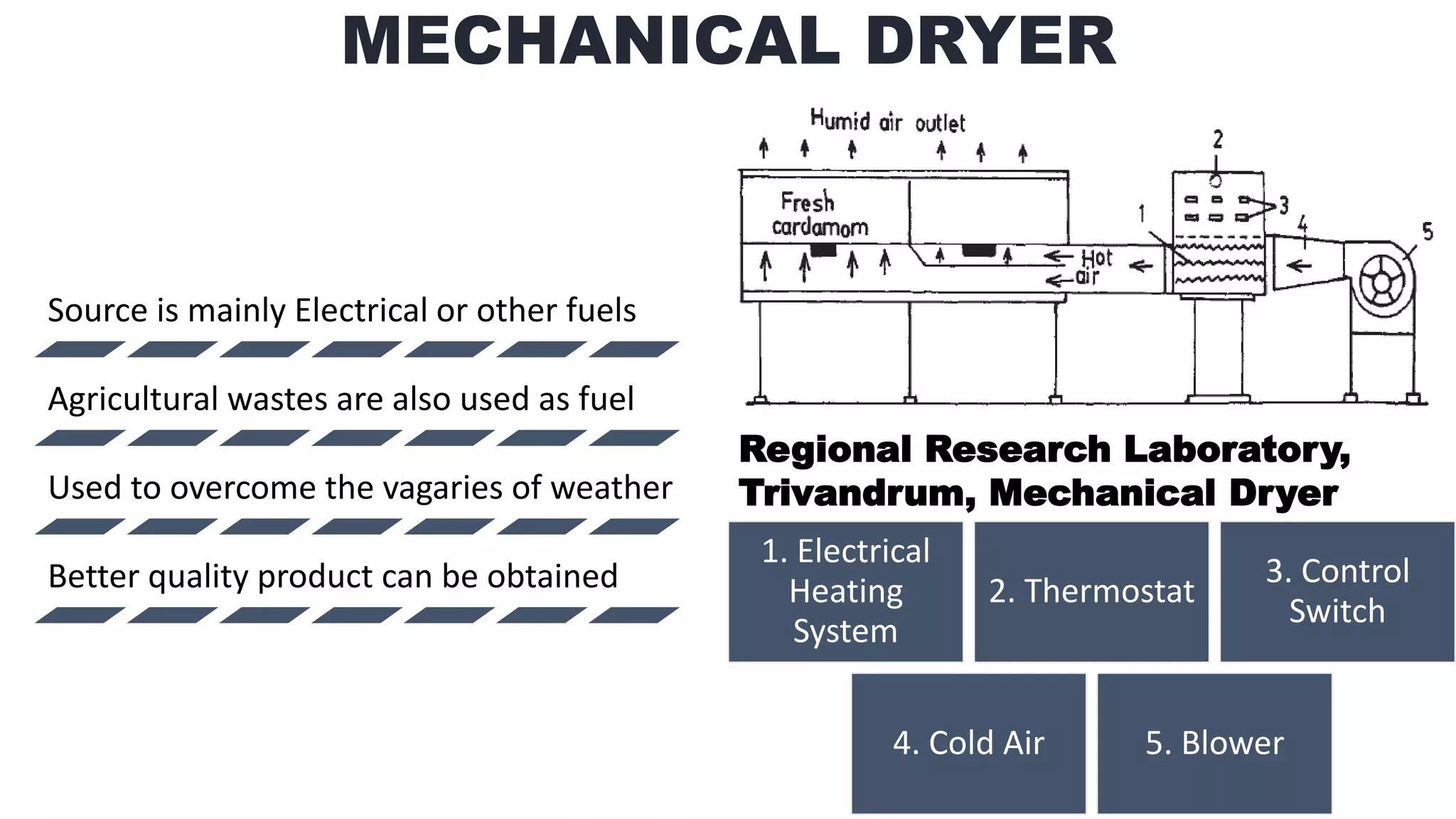

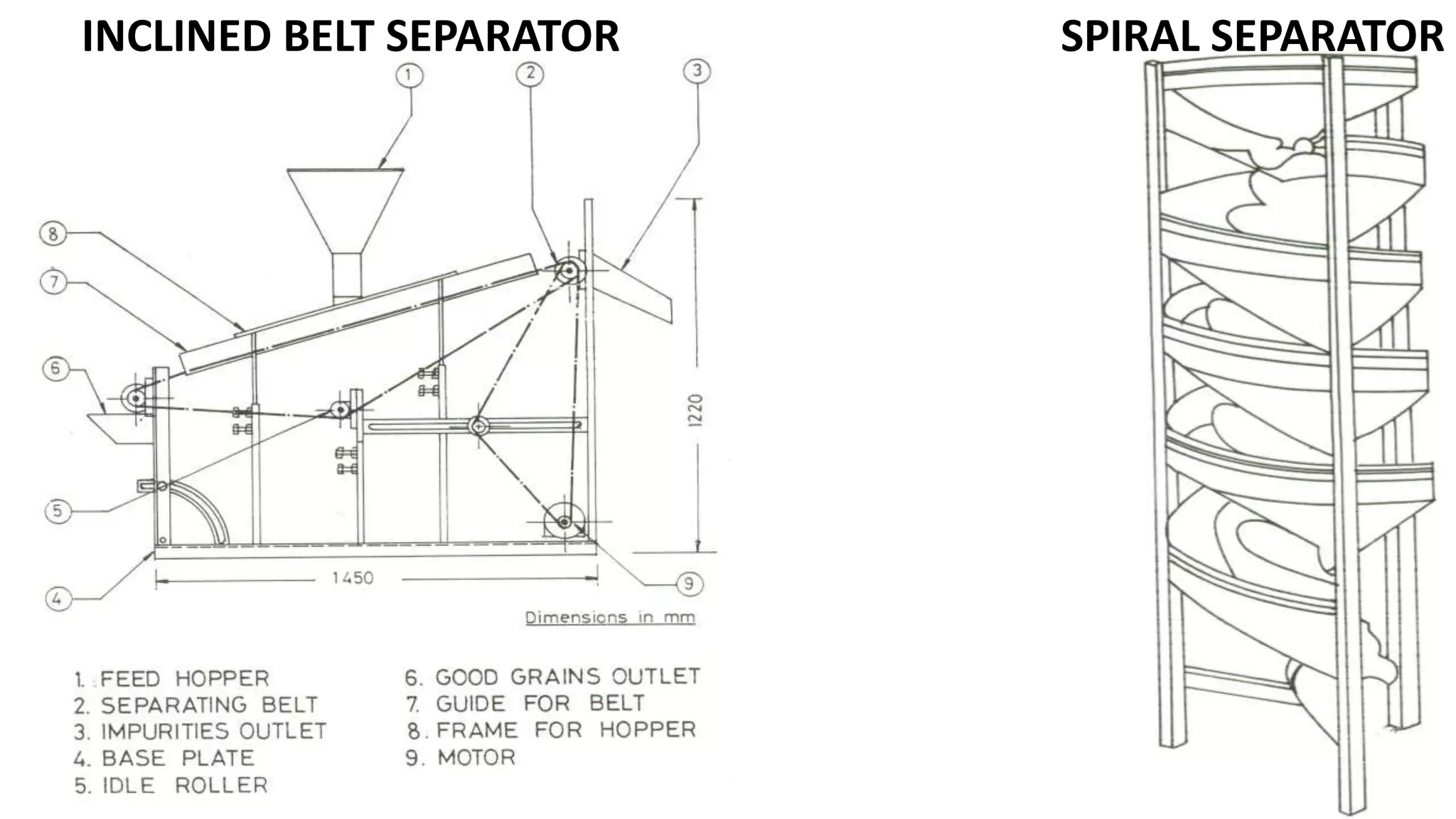

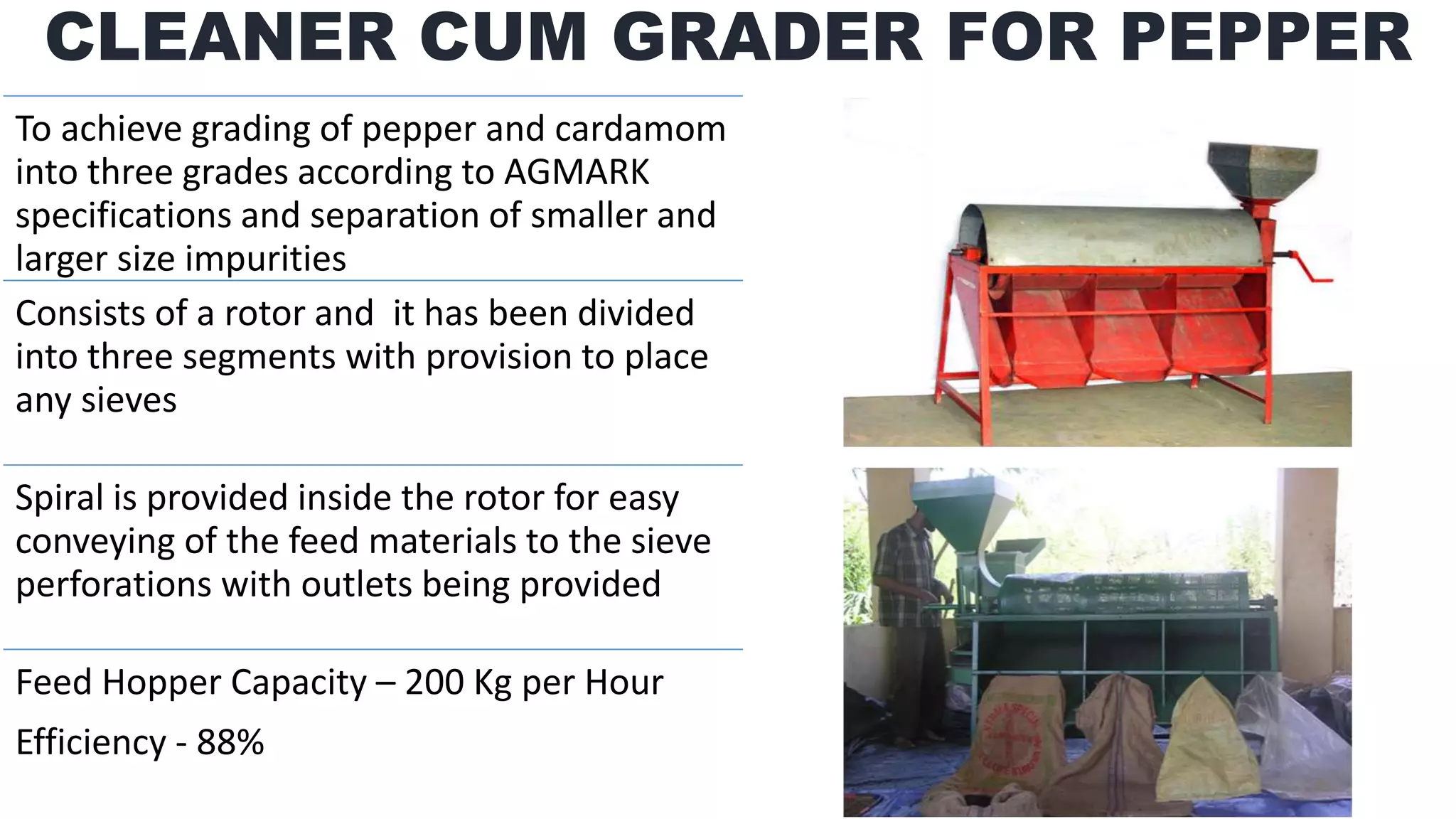

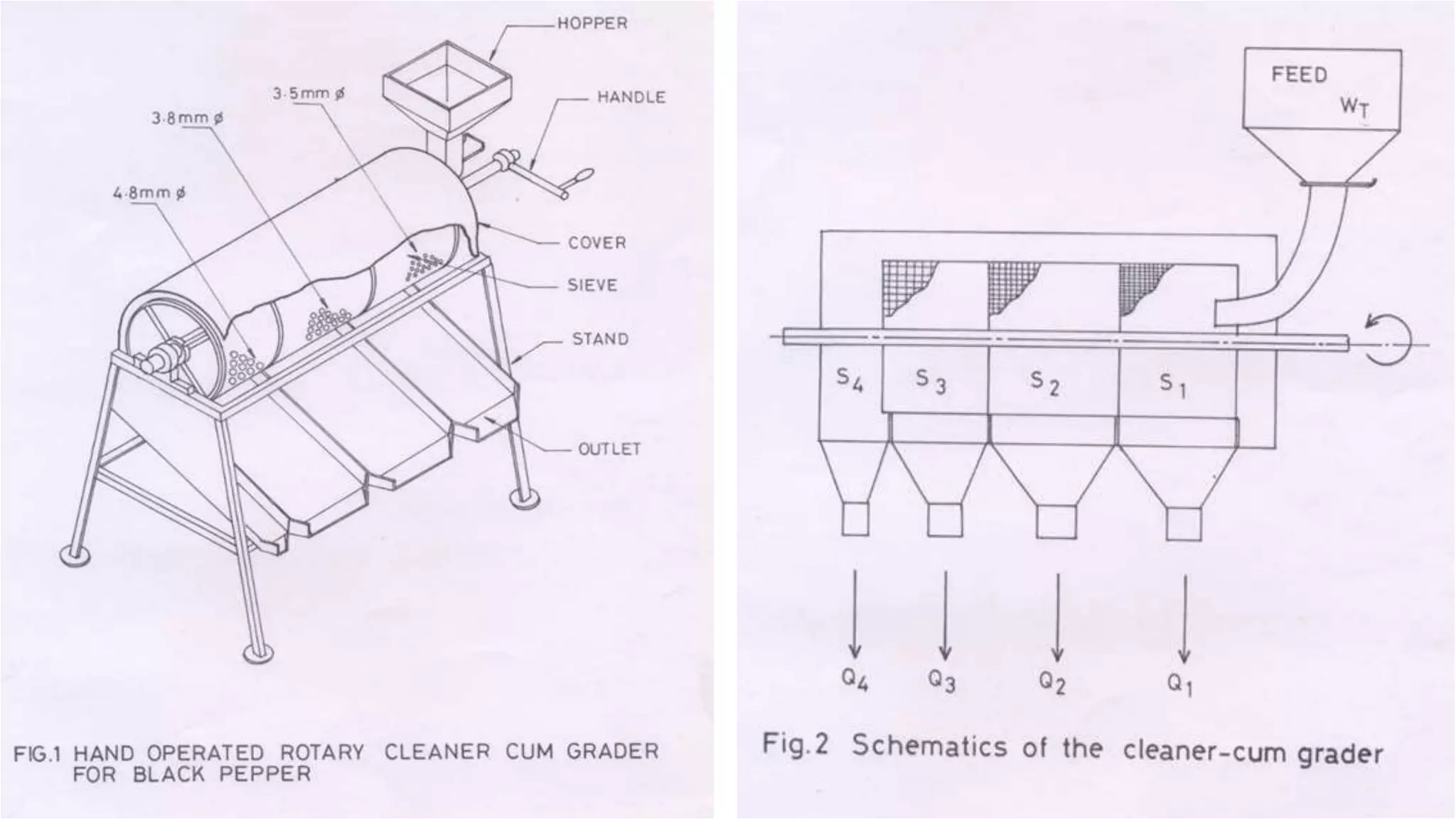

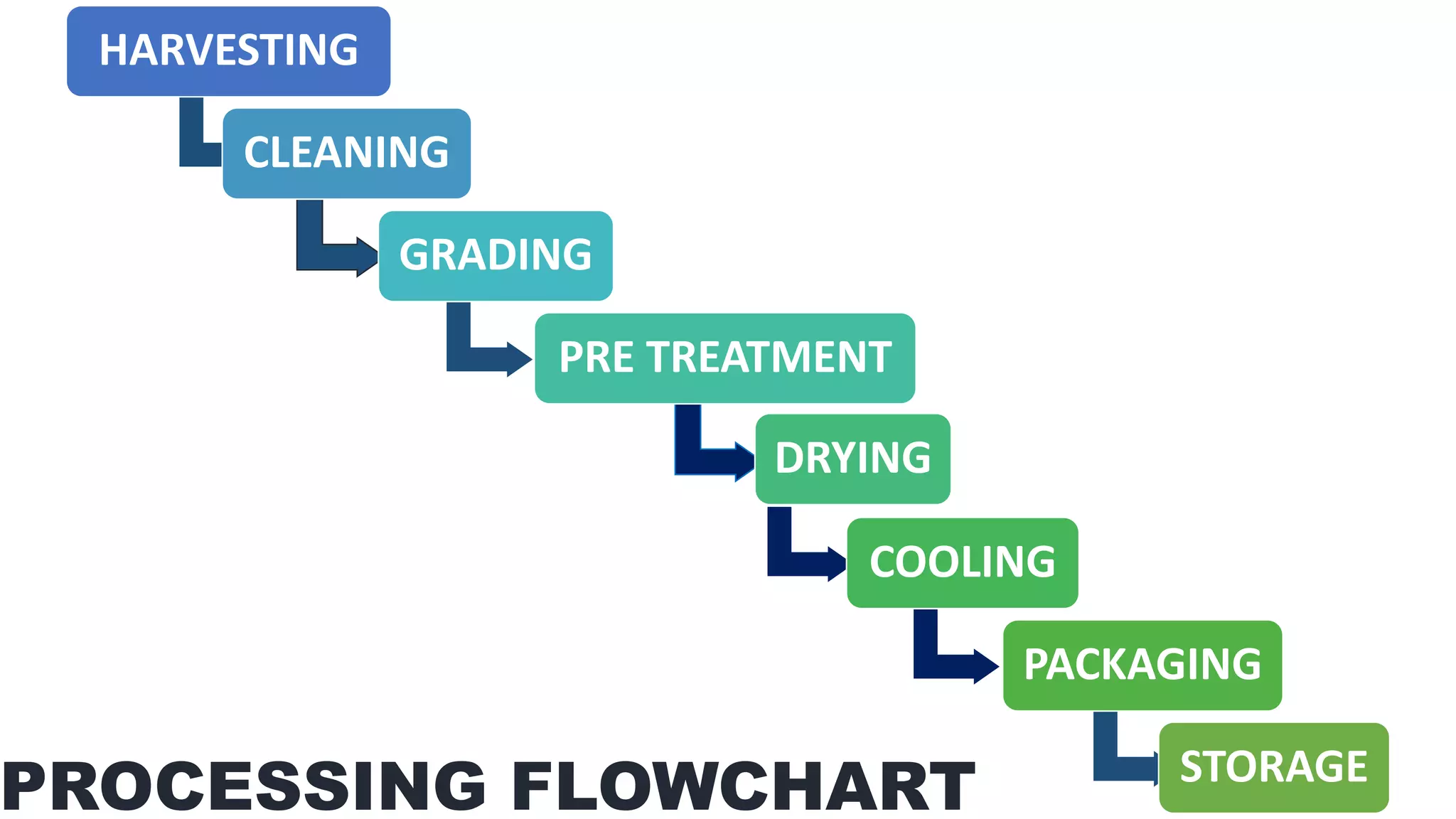

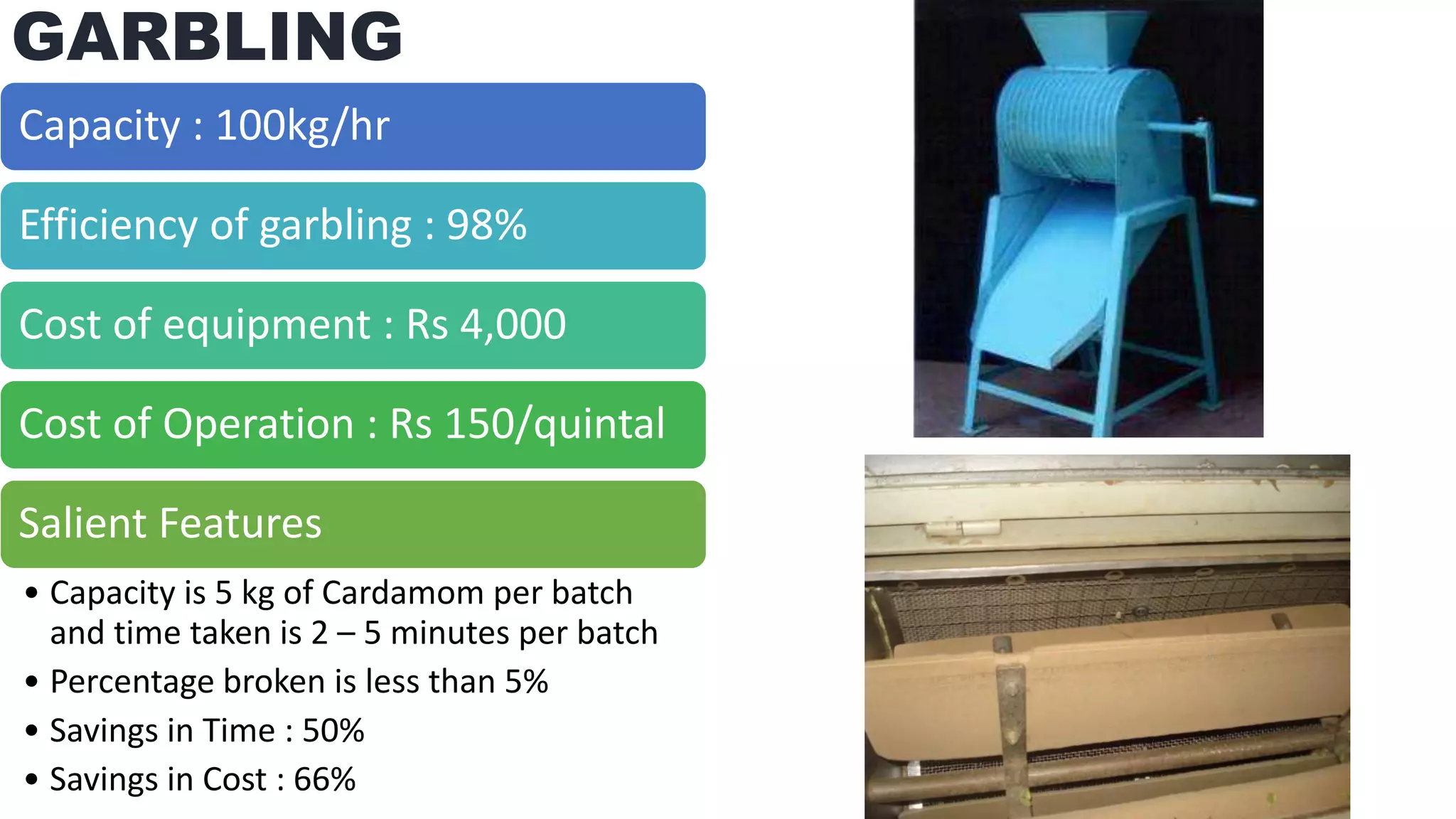

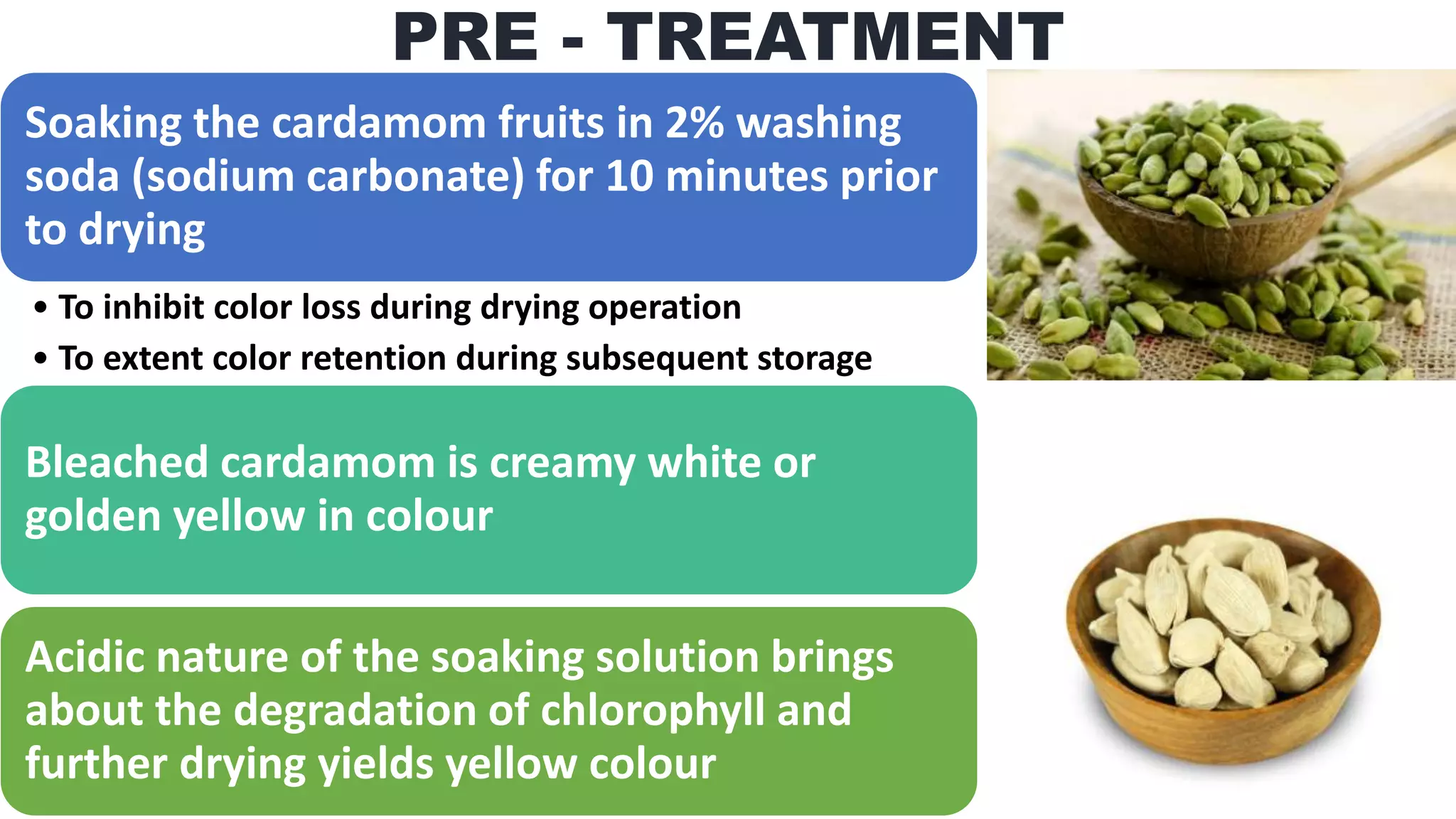

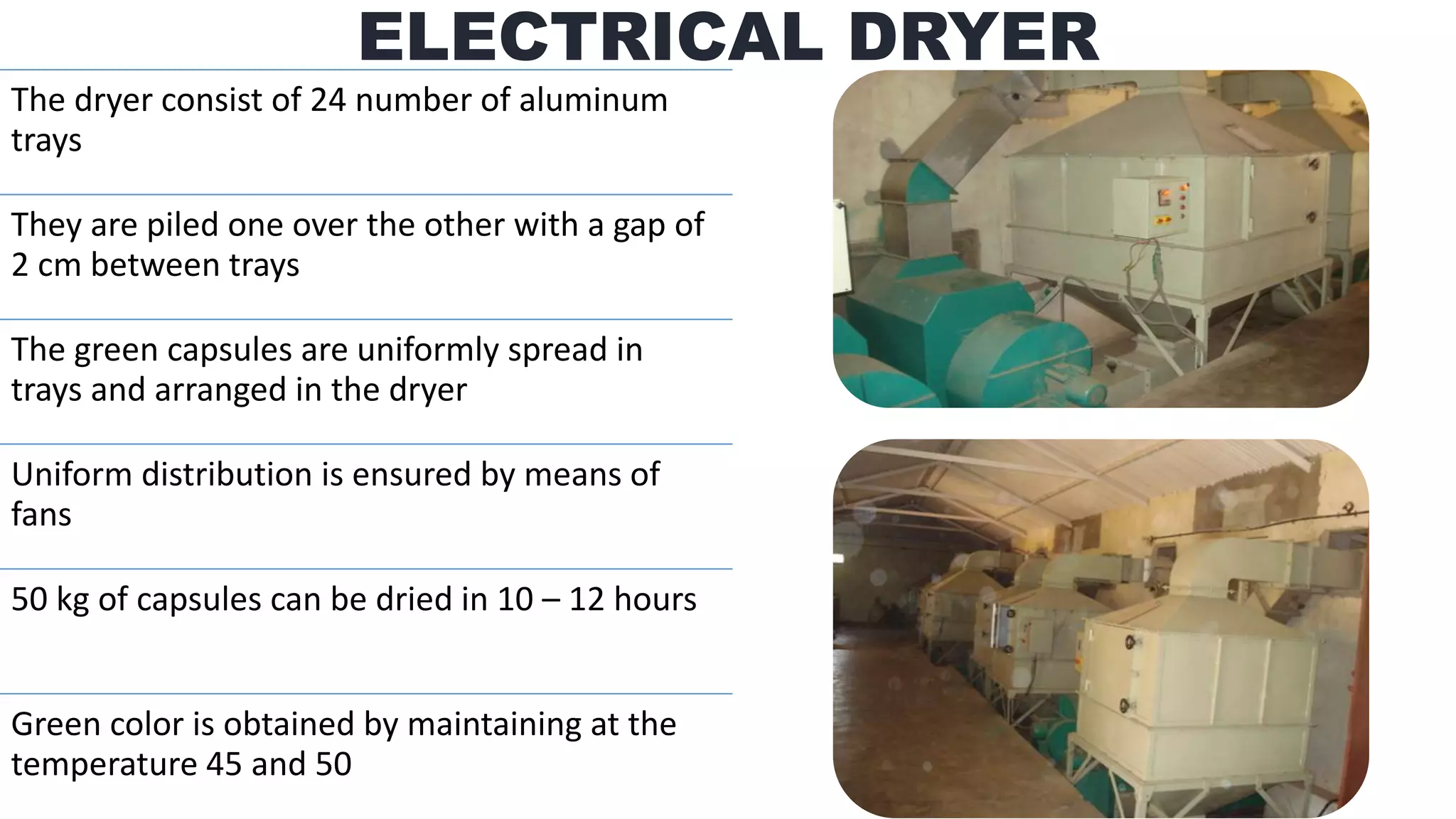

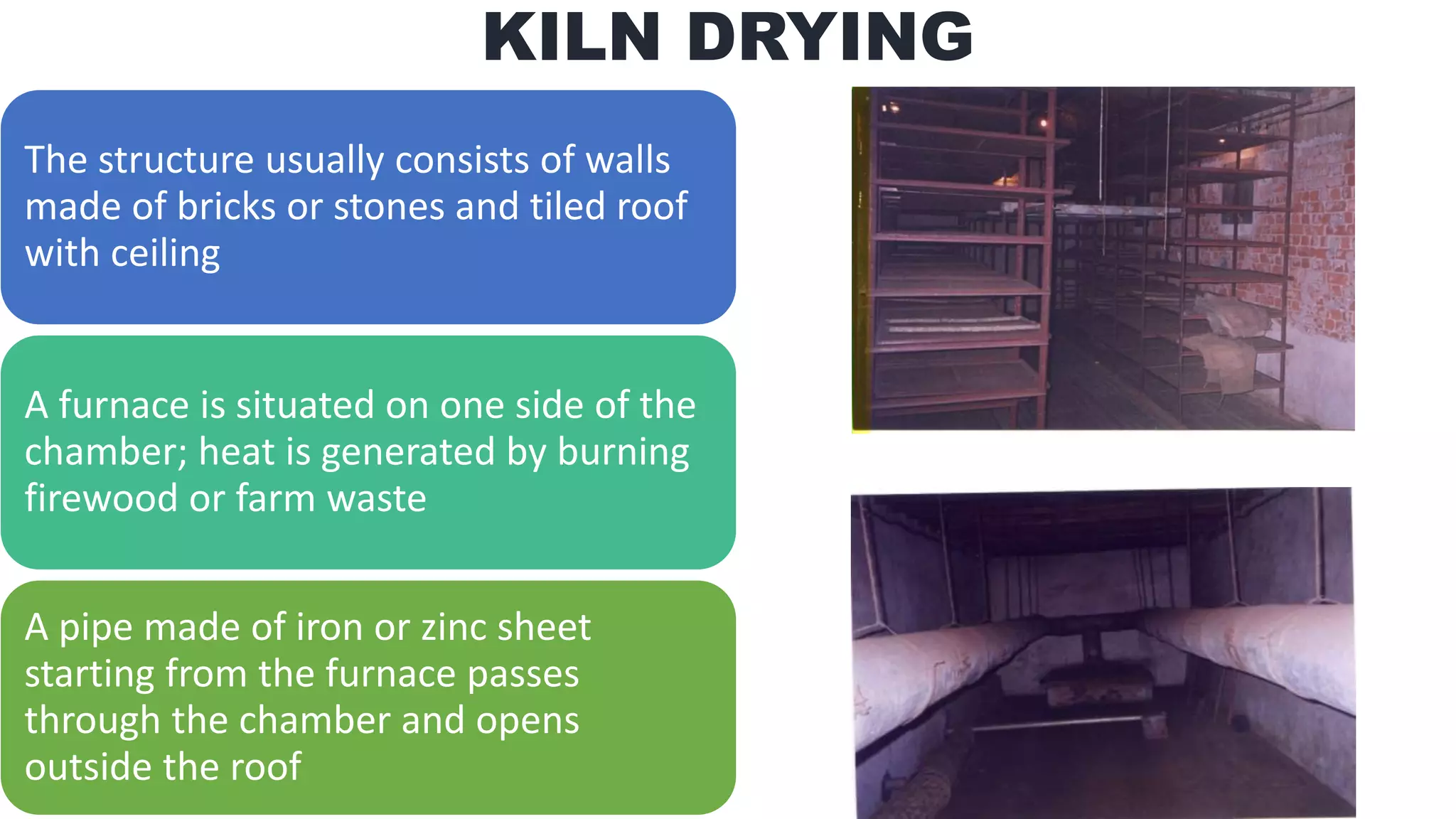

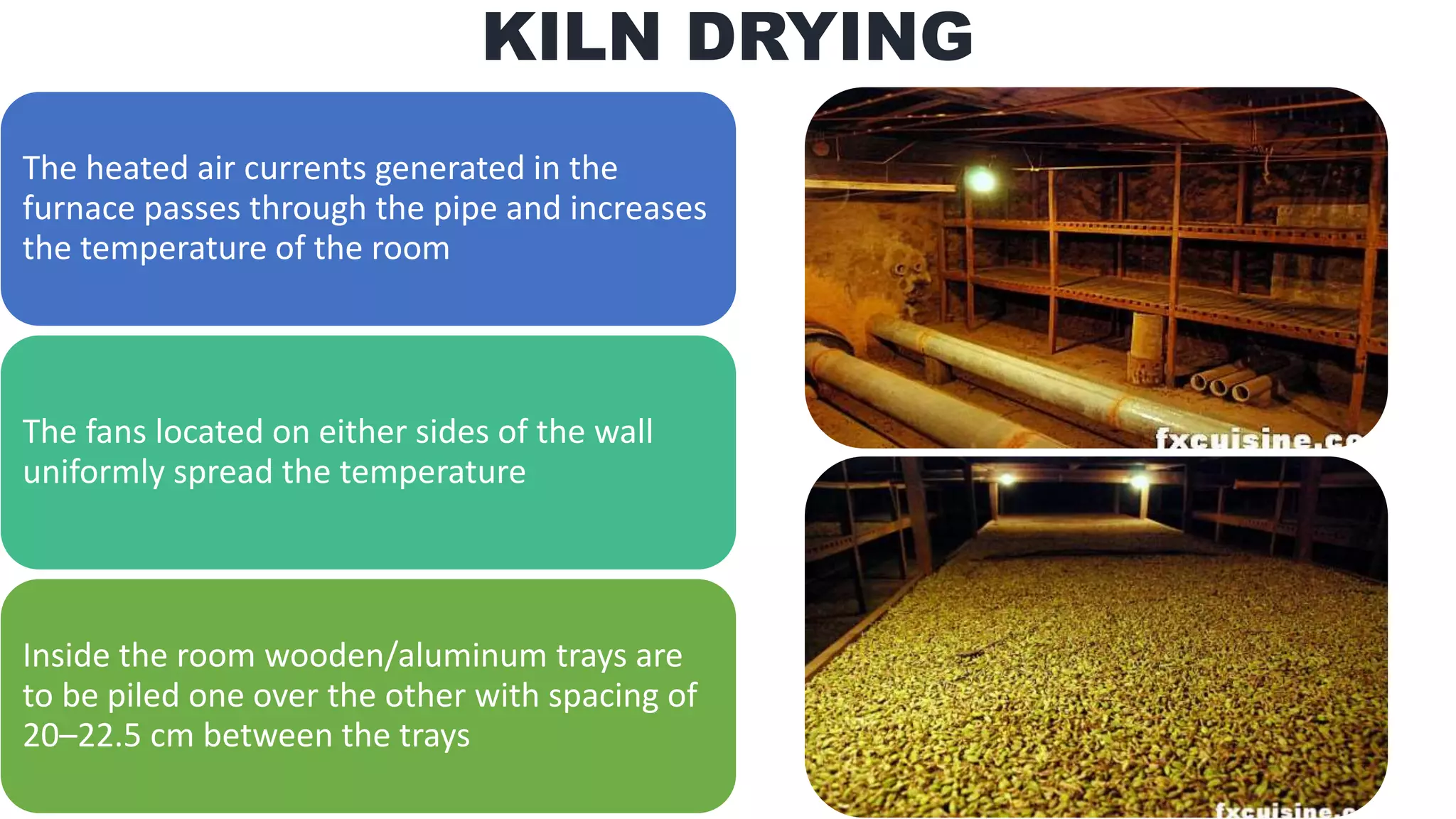

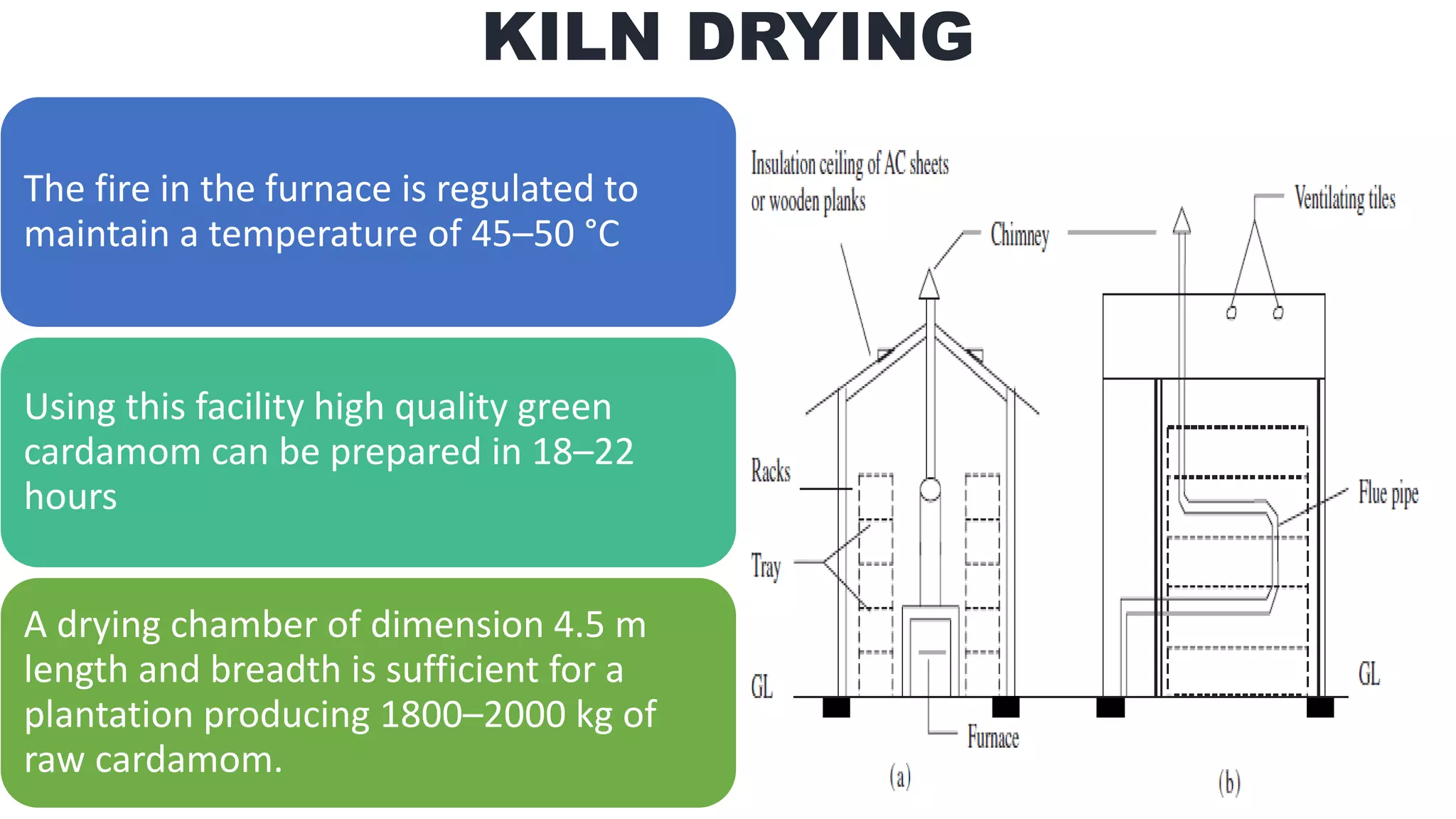

The document outlines the process engineering aspects of harvesting, processing, and storing spices like pepper and cardamom. It details various methods and equipment used for threshing, drying, cleaning, grading, and packaging, highlighting costs, efficiencies, and operational practices. Additionally, it emphasizes the importance of moisture control during storage to prevent quality loss and contamination.